Preparation method of bionic bracket material in bone tissue engineering

A technology of bone tissue engineering and scaffold materials, which is applied in the field of biomaterials and tissue engineering for the regeneration and repair of bone tissue defects. The effect of promoting new bone growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

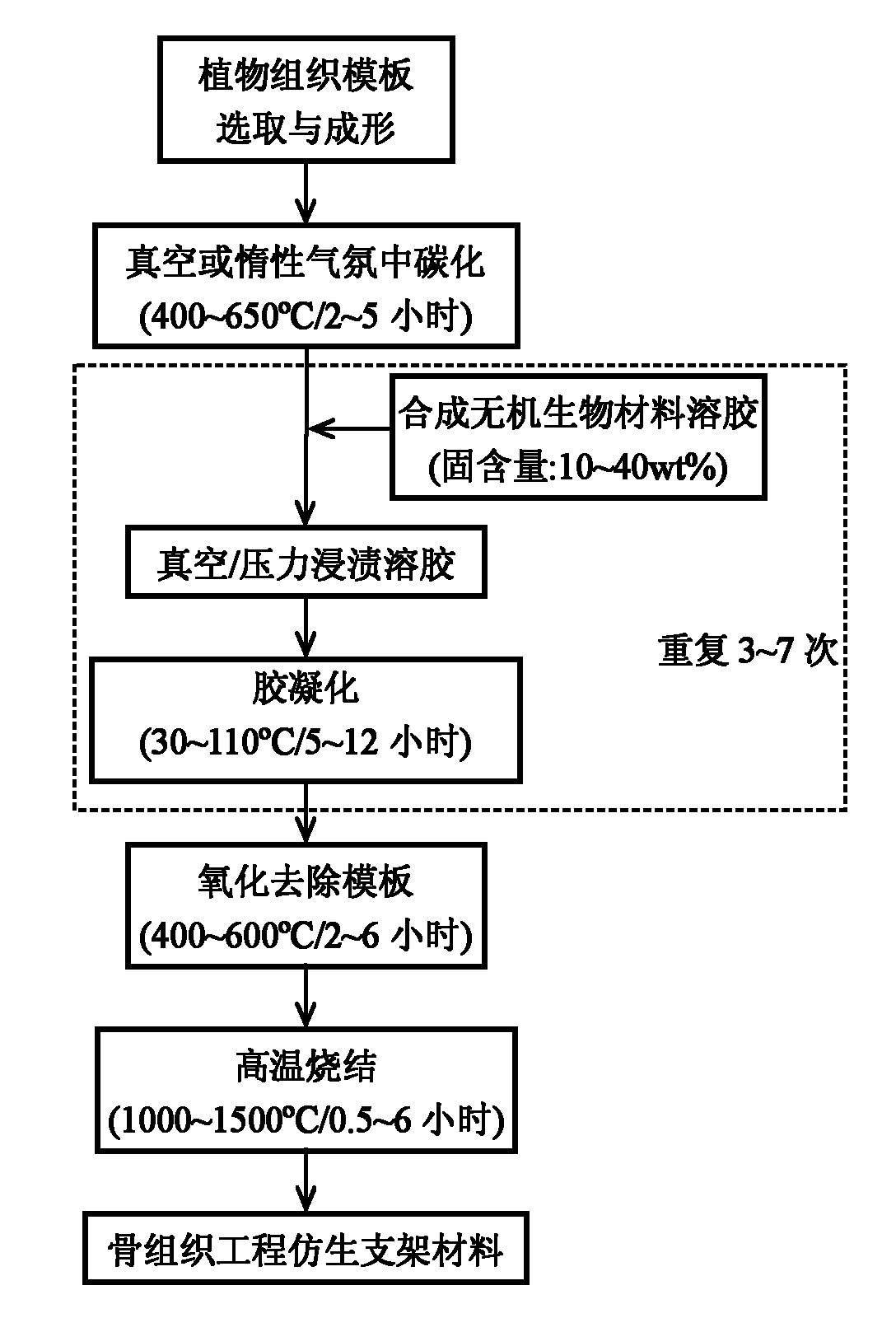

[0031] refer to figure 1 As shown, the preparation method includes the following steps: (1) mechanically processing a certain shape of wood, rattan or straw plant tissue templates, such as paulownia, pine, wisteria, sugar cane, etc., in a vacuum or inert gas environment with 1 Heat up to 400-650°C at a heating rate of ~15°C / min, and carbonize for 2-5 hours; (2) Using calcium nitrate, sodium nitrate, ethyl orthosilicate, butyl titanate, triethyl phosphate, etc. as raw materials, Prepare the mixture according to the chemical composition of the target product, dissolve it in a mixed solvent of ethanol and water at a concentration of 0.5-2mol / L, and synthesize hydroxyapatite sol and 45S5 glass sol with a solid content of 10-40wt% in an environment of pH 2-11 , calcium silicate sol, calcium titanate sol, etc.; (3) the porous carbon obtained in (1) is placed in an impregnation tank, first vacuumed and kept for 0.5 to 3 hours, after adding the inorganic sol obtained in (2), the Use ...

Embodiment 1

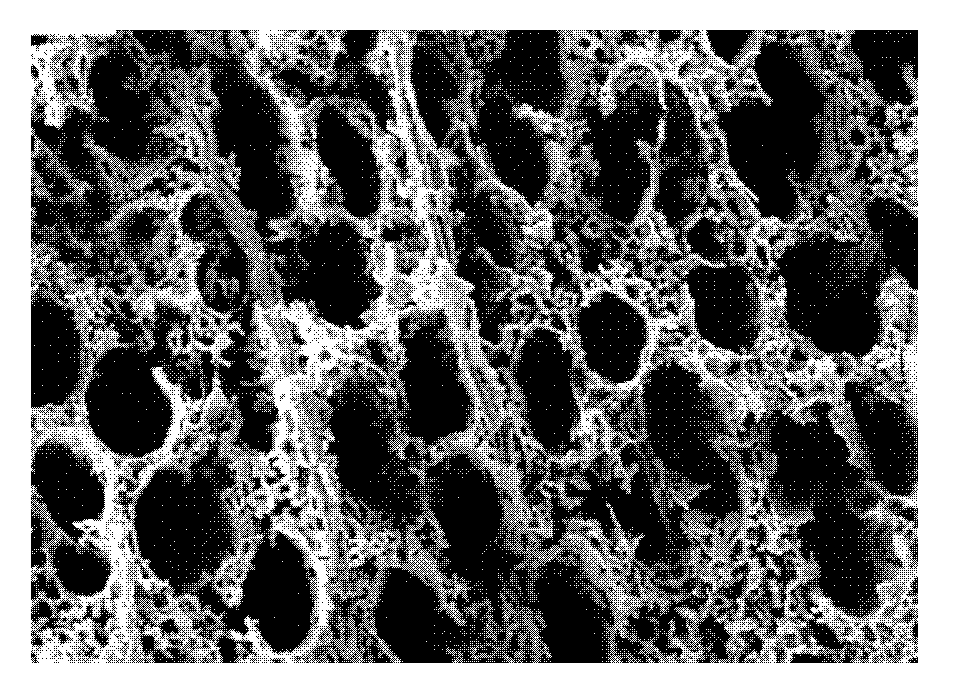

[0036] (1) Plant template selection and forming: choose the woody rattan wisteria as the initial template, its tubular hole diameter is 20-240 μm, the porosity is 86%, and it is made into a cylindrical block material through mechanical addition;

[0037] (2) Carbonization: Place the bulk material in (1) in a vacuum resistance furnace, heat it to 550°C at a heating rate of 5°C / min, and keep it carbonized for 3 hours to obtain a porous material that retains the external geometry and internal pore structure of the template. carbon;

[0038] (3) Sol preparation and vacuum / pressure impregnation: according to the Ca / P molar ratio of 1.67, measure the corresponding amount of calcium nitrate and triethyl phosphate, under the catalysis of hydrochloric acid, in a mixed solvent of ethanol and water, prepare at room temperature The hydroxyapatite precursor sol with a solid content of 20wt%; after aging at room temperature for 12 hours, the porous carbon is impregnated by a vacuum / pressure...

Embodiment 2

[0041] (1) plant template selection and shaping: same as (1) in embodiment 1;

[0042] (2) Carbonization: Place the bulk material in (1) in a vacuum resistance furnace, heat it to 500°C at a heating rate of 2°C / min, and keep it carbonized for 5 hours to obtain a porous material that retains the external geometry and internal pore structure of the template. carbon;

[0043] (3) Sol preparation and vacuum / pressure impregnation: according to the composition of SiO 2 ,P 2 o 5 , CaO and Na 2 The mass percent of O is respectively 45wt%, 6wt%, 24.5wt% and 24.5wt%, measures corresponding amount of tetraethyl orthosilicate, triethyl phosphate, calcium nitrate and sodium nitrate respectively, under citric acid catalysis, In a mixed solvent of ethanol and water, 45S5 bioactive glass precursor sol with a solid content of 30wt% was prepared at room temperature; after aging at room temperature for 24 hours, the porous carbon was impregnated by vacuum / pressure impregnation process, as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com