Solar battery based on silicon nano material

A technology of solar cells and silicon nanometers, which is applied in the field of solar cells, can solve problems such as no solar cell research, and achieve the effects of improving photoelectric conversion efficiency, wide electrochemical window, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] see Figure 13 Shown, a kind of solar cell based on silicon nanostructure comprises n-type silicon chip 6, and described silicon chip is provided with conductive glass (conductive glass comprises transparent glass 1 and conductive film layer 2), between conductive glass and silicon chip It is surrounded by an insulating sealing layer 3, forming an electrolyte chamber between the conductive glass and the silicon wafer, that is, the hole transport layer 4, and the electrolyte chamber is provided with an ionic liquid electrolyte; the back of the silicon wafer is provided with an extraction electrode 7, forming an ohmic electrode structure . Silicon nanostructures 5 are provided on the silicon wafer 6 .

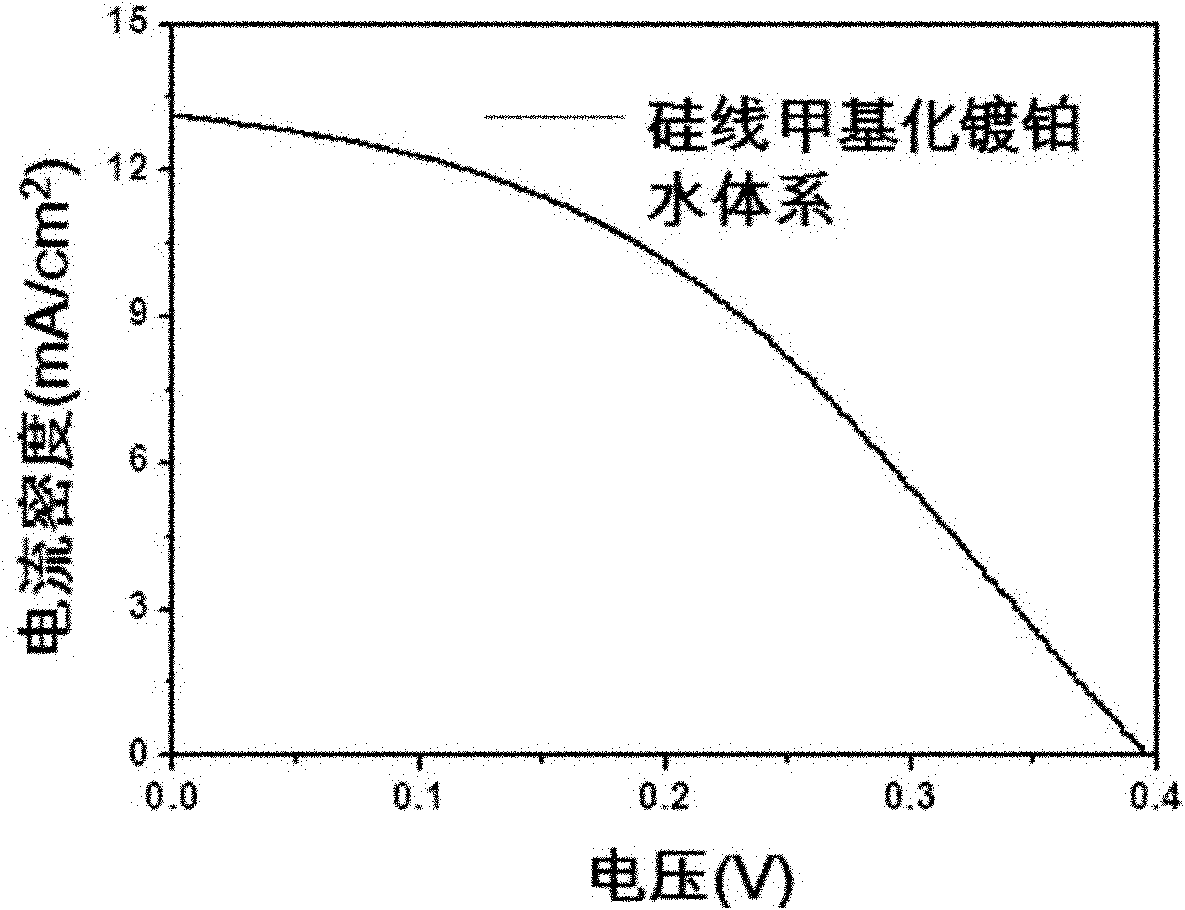

[0060] The preparation method is as follows: first, the n-type silicon wafer is etched in a mixed solution of 0.02M silver nitrate and 5M hydrofluoric acid at room temperature, and silicon nanowires are prepared by etching on the n-type silicon substrate; Immerse the sil...

Embodiment 2

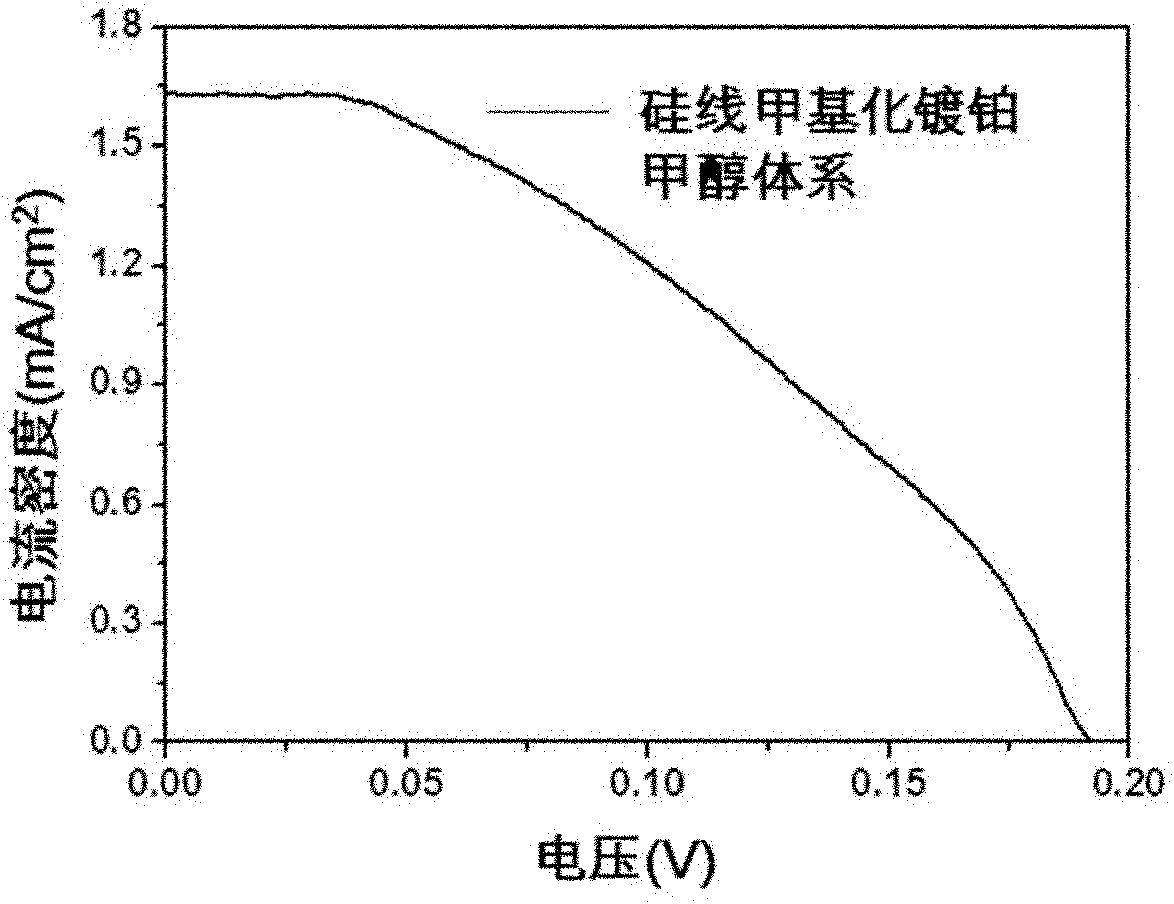

[0074] First, the n-type silicon wafer is immersed in a mixture of 5% hydrofluoric acid and 10mM sodium dodecylsulfonate at room temperature for electrochemical etching. The etching condition is a bias voltage of 5V, backlighting, and a current density of 10mAcm. -2 , the etching time is 30 minutes, and the porous silicon array can be prepared on the silicon substrate, and then the silicon wafer is soaked in 10% potassium hydroxide (KOH) to remove the microporous layer on the surface; then the silicon wafer is immersed in 5M hydrofluoric acid Acid solution makes the surface to form Si:H bond; Put into the saturated chlorobenzene solution of phosphorus pentachloride, the tetrahydrofuran solution (1M) of methylmagnesium chloride and carry out treatment to make its surface methylation; Deposit 5-10nm platinum particles on the surface of porous silicon and indium tin oxide films; then use high vacuum thermal evaporation to deposit Al films on the bottom of the silicon substrate to ...

Embodiment 3

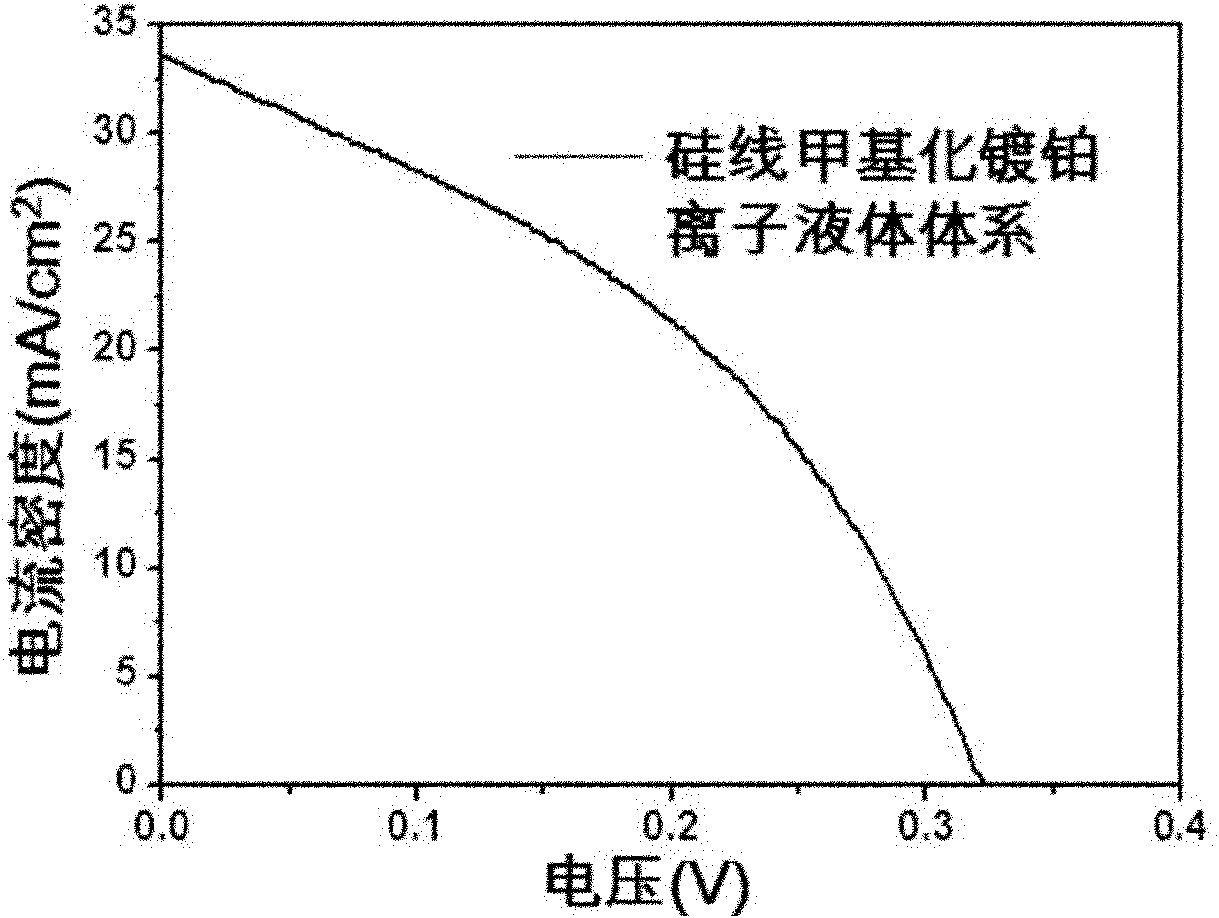

[0080] First, immerse the n-type silicon wafer in a mixed solution of 0.02M silver nitrate and 5M hydrofluoric acid to etch at room temperature, and etch on the n-type silicon substrate to prepare silicon nanowires; then soak the silicon wafer in concentrated nitric acid solution for at least one hour To remove elemental silver; then immerse the silicon wafer in a 5M hydrofluoric acid solution to form Si:H bonds on the surface; deposit 5-10nm platinum particles on the surface of the silicon nanowire array and the surface of the indium tin oxide film by thermal decomposition, respectively, Then use high vacuum thermal evaporation method to deposit Al film on the bottom surface of silicon substrate to form ohmic contact electrode; and Mix evenly at a volume ratio of 2:1 and add redox electron pairs of iodine, drop a few drops on the silicon nanowires, and finally cover the ionic liquid with an indium tin oxide conductive glass and package it to obtain an ionic liquid-based Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com