Advanced treatment method for diatomite for reclaimed-water recycling

A diatom concentrate and advanced treatment technology, applied in the field of water treatment, can solve the problem that the effluent cannot meet the reuse water standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

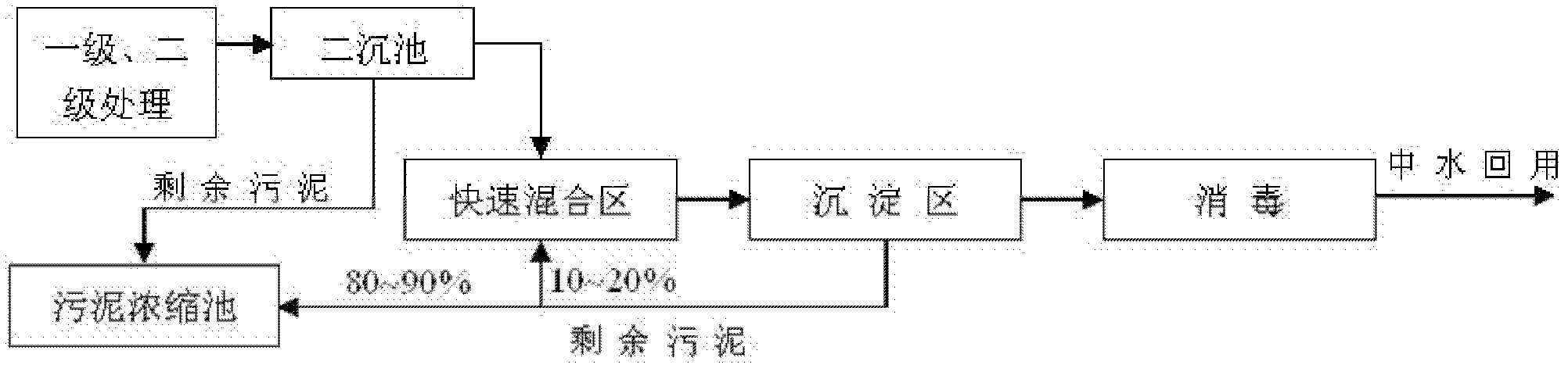

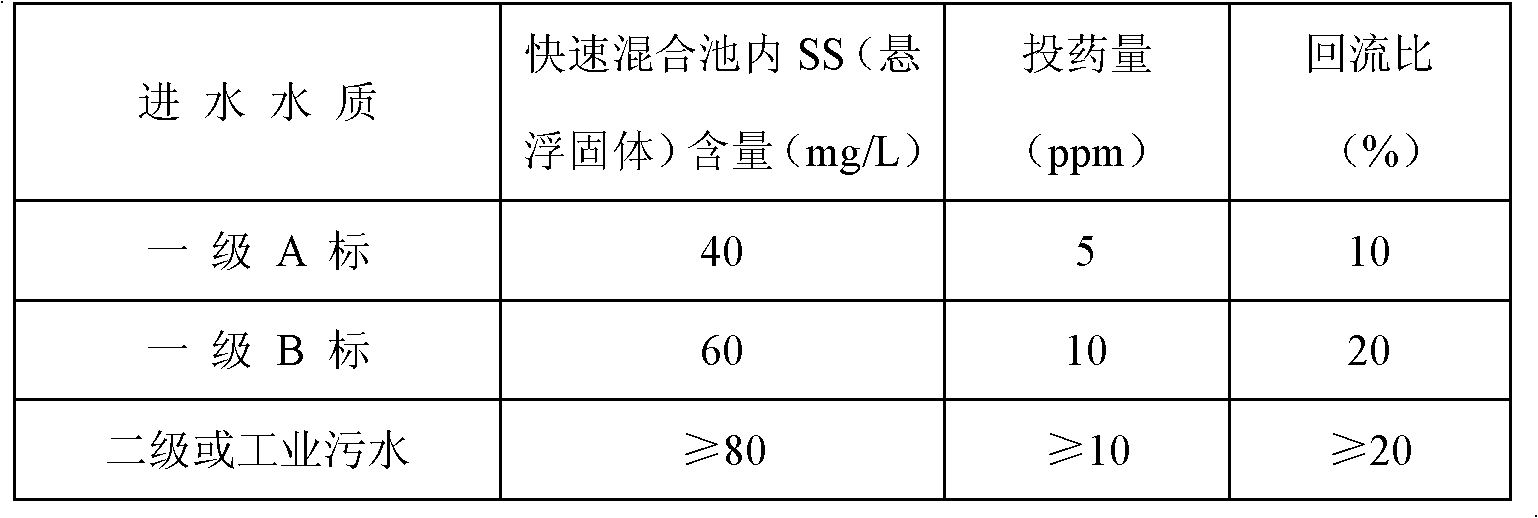

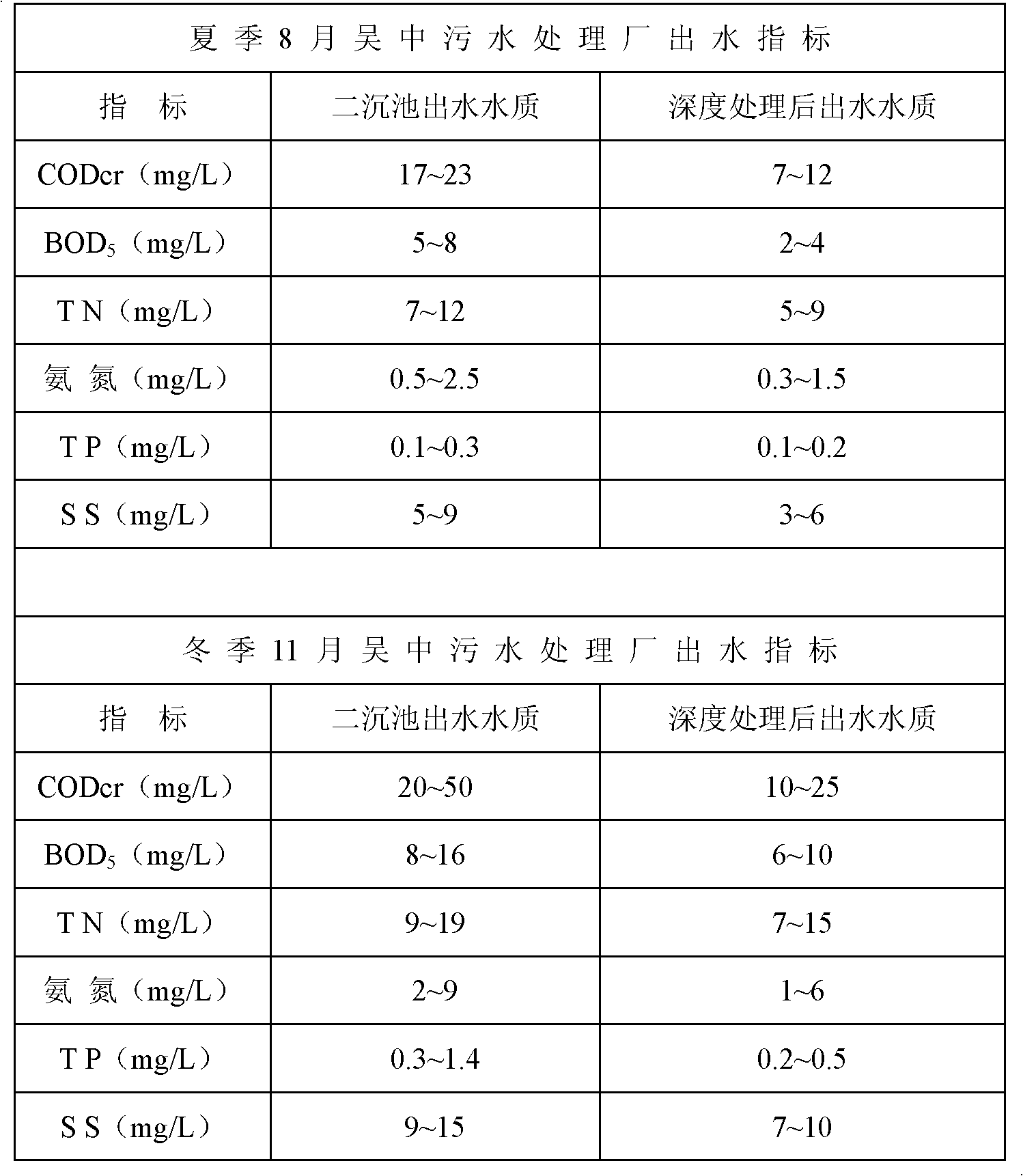

Method used

Image

Examples

Embodiment 1

[0035] The fermentative culture of embodiment 1 producing flocculation microorganism

[0036] Under sterile conditions, after the three strains (CGMCC No.3515, CGMCC No.3514 and CGMCC No.3516) were activated on the slant, they were respectively inoculated into LB medium shake flasks, the shaker speed was 200r / min, and the culture time was 50h. In the mid-logarithmic growth stage, inoculate the first-level seed tanks with 5% inoculation amount, and then enlarge and cultivate the second-level seed tanks step by step, and the number of bacteria obtained can reach OD value of 1.0-1.2×10 9 / ml of fermentation liquid. The fermentation medium is glucose 1%, ammonium sulfate 0.15%, dipotassium hydrogen phosphate 0.05%, potassium dihydrogen phosphate 0.05%, magnesium sulfate 0.002%, NaCl 0.02%, calcium chloride 0.01%, the rest is tap water, pH7.0, Fermentation at 28~30℃, tank pressure 0.5kg / cm 2 , the ventilation rate is measured by the volume of fermentation broth in m 3 / air volum...

Embodiment 2

[0037] The preparation of embodiment 2 biological flocculants

[0038] The fermented liquid prepared in Example 1 was centrifuged at 5000rpm for 30min to remove the thallus (precipitation), concentrate (conventional ultrafiltration, decompression) the supernatant, and add CaCl equivalent to 0.1% of the supernatant weight to the supernatant. 2 and 2.5 times the volume of supernatant liquid ethanol, let stand at room temperature for 40 minutes, then centrifuge at 12000g for 15 minutes with a centrifuge, discard the supernatant, and obtain precipitate 1 for subsequent use; dissolve precipitate 1 with 3.0%, pH5 sodium chloride solution (sodium chloride solution just can dissolve precipitate 1 and get final product), absorb with 12% hexadecyltrimethylammonium bromide solution of 1 times sodium chloride solution volume, then obtain precipitate 2 for subsequent use through centrifugation; Dissolve the precipitate 2 with 10% sodium chloride and stir for 12 hours, add absolute ethanol ...

Embodiment 3

[0040] In the diatomaceous earth that diatom shell content is 85wt%, add the diatomaceous earth weight 30wt% that is made of Providencia sp.12A (CGMCC No.3515), Stenotrophomonas sp.46C (CGMCC No.3514) and Myroides sp. 122B (CGMCC No.3516) bio-flocculants prepared by three strains (the weight ratio of the three bio-flocculants is 1:1:2 in sequence), after uniform stirring, it is prepared into diatomite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com