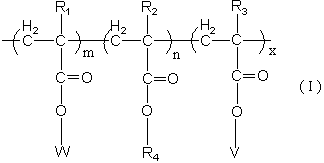

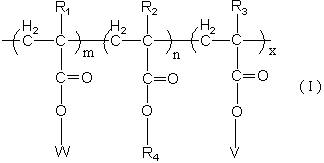

Hollow fibrous membrane with cell membrane simulation structure and construction method thereof

A technology of imitating cell membrane and construction method, which is applied in the field of hollow fiber membrane imitating cell membrane structure and its construction, can solve the problems of unstable coating, complex chemical reaction fixing coating process, unsatisfactory modification effect, etc., and achieve good biophase Capacitance, Surface Hydrophilicity and Biocompatibility Improvement, Stability Enhancement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 1.2 g of methacryloxypropyltrimethoxysilane (MPS) monomer and 2.8 g of n-butyl methacrylate (BMA) monomer and dissolve them in 80 ml of absolute ethanol in a 250 ml three-necked bottle. 3.6 g of methacryloyloxyethoxyphosphorylcholine (MPC) and 0.050 g of initiator AIBN were respectively dissolved in 40 ml of absolute ethanol. After 30 minutes of deoxygenation by nitrogen gas, 30% of the MPC solution and the AIBN solution were simultaneously added at 60° C., and the remaining part was added dropwise within 2 hours. It was then condensed under reflux at 65°C and stirred for 16 hours. The product was precipitated with ether, rinsed, washed with acetonitrile, and dried with 1 The molar content of each component of MPC, BMA and MPS measured by H nuclear magnetic resonance spectrum is 40%, 42% and 18%, and the terpolymer is marked as PMBT442.

Embodiment 2

[0029] Take 0.95 g of methacryloxypropyltrimethoxysilane (MPS) monomer and 1.2 g of lauryl methacrylate (LMA) monomer and dissolve them in 60 ml of anhydrous isopropanol in a 250 ml three-necked bottle middle. Dissolve 1.8 g of methacryloyloxyethoxyphosphorylcholine (MPC) and 0.040 g of initiator AIBN in 40 ml of absolute ethanol. After passing through nitrogen to remove oxygen for 30 minutes, add 30% of the MPC and AIBN solution at 80° C., and the rest is added dropwise within 2 hours. It was then reflux condensed at 80°C and stirred for 16 hours. The product was precipitated with ether, rinsed, washed with acetonitrile, and dried with 1 The molar content of each component of MPC, BMA and MPS measured by H nuclear magnetic resonance spectrum is 52%, 31% and 17%, and the terpolymer is marked as PMLT532.

Embodiment 3

[0031] PMBT442 was formulated into a 1.0 mg / ml methanol solution, and the polypropylene hollow fiber membrane was immersed in the solution, taken out after 20 seconds and dried in a fume hood to form a coating. The coating was treated in 10% triethylamine aqueous vapor at room temperature for 3 days to obtain a cross-linked and stable coating. The advancing angle in contact with water is 80 degrees, and the receding angle is 60 degrees. Compared with the uncoated modified polypropylene fiber, the advancing angle is reduced by 20 degrees, and the receding angle is reduced by 40 degrees, such as figure 1 shown. After the coating was soaked in ethanol and 2% sodium dodecylsulfonate aqueous solution, the contact angle did not increase significantly, which proved that the coating had good stability. X-ray photoelectron spectroscopy shows that N, P, and Si elements in the polymer appear on the surface of the modified fiber, which proves that the polymer exists stably on the fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com