Preparation method of chitosan-based drug-loaded composite antibacterial microfiber membrane

A superfine fiber, composite antibacterial technology, applied in medical science, textiles and papermaking, bandages, etc., can solve the problems of unclear chronic toxicity, need to be further confirmed, and nano-silver is easy to be oxidized, and achieve good biological phase. Compatibility and biodegradability, promoting wound healing, reducing medical waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

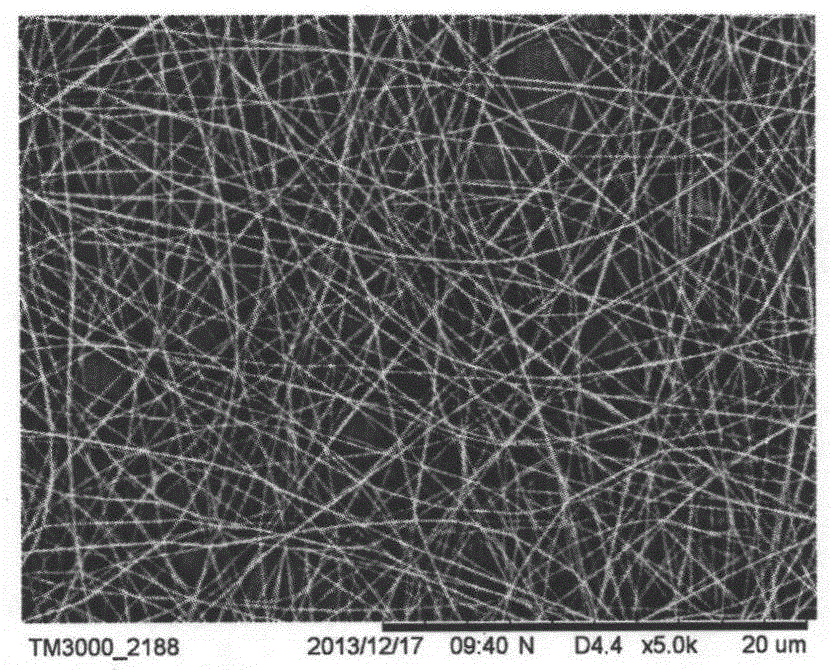

Embodiment 1

[0028] Take by weighing a certain amount of distilled water and glacial acetic acid respectively with electronic balance, be made into mass fraction and be 90% acetic acid aqueous solution, take by weighing 9.475g mass fraction and be 90% acetic acid aqueous solution, add the ciprofloxacin hydrochloride powder of 0.025g to it , stirred with a magnetic stirrer to fully dissolve, weighed 0.05g of PEO and 0.45g of CS powder and dissolved in the above solution, continued to stir with a magnetic stirrer for 12h, then oscillated with ultrasonic waves for 0.5h, and finally stood for 1h for defoaming to obtain a uniform, Stable spinning solution.

[0029] Add the above spinning solution into the syringe for electrospinning, the spinning voltage is 10kv, the feeding rate is 0.5mL / h, the receiving distance is 20cm, the ambient temperature is 18°C, and the relative humidity is 35%. Electrospinning was carried out for 5 h.

[0030] The prepared chitosan-based drug-loaded composite antiba...

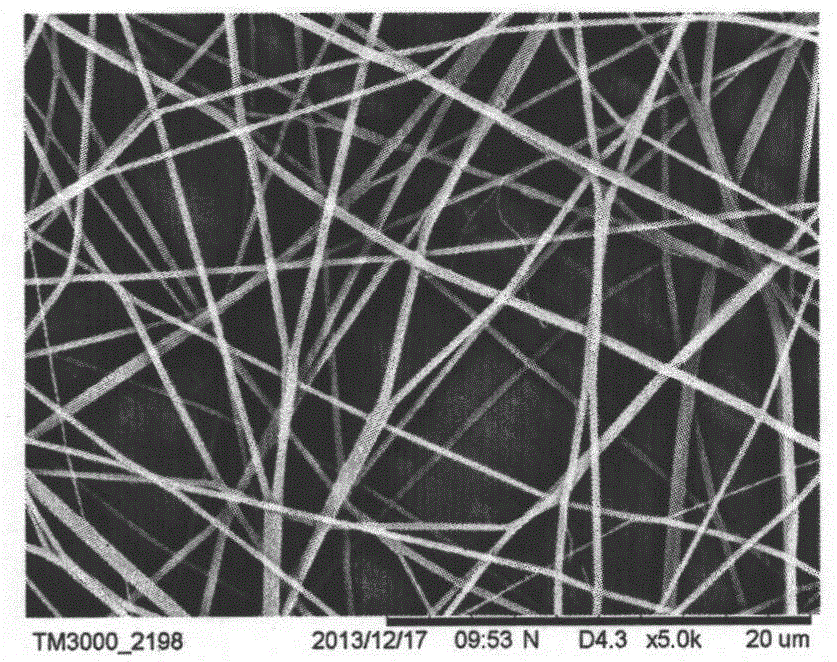

Embodiment 2

[0033]Take by weighing a certain amount of distilled water and glacial acetic acid respectively with electronic balance, be made into mass fraction and be 90% acetic acid aqueous solution, take by weighing 9.45g mass fraction and be 90% acetic acid aqueous solution, add the ciprofloxacin hydrochloride powder of 0.05g to it , stirred with a magnetic stirrer to fully dissolve it, weighed 0.05g of PEO and 0.45g of CS powder and dissolved in the above solution, continued to stir with a magnetic stirrer for 12h, then oscillated with ultrasonic waves for 1h, and finally stood for defoaming for 1h to obtain a uniform, Stable spinning solution.

[0034] Add the above spinning solution into the injector for electrospinning, the spinning voltage is 16kv, the feeding rate is 0.8mL / h, the receiving distance is 20cm, the ambient temperature is 20°C, and the relative humidity is 30%. Electrospinning was carried out for 5 h.

[0035] The prepared chitosan-based drug-loaded composite antibac...

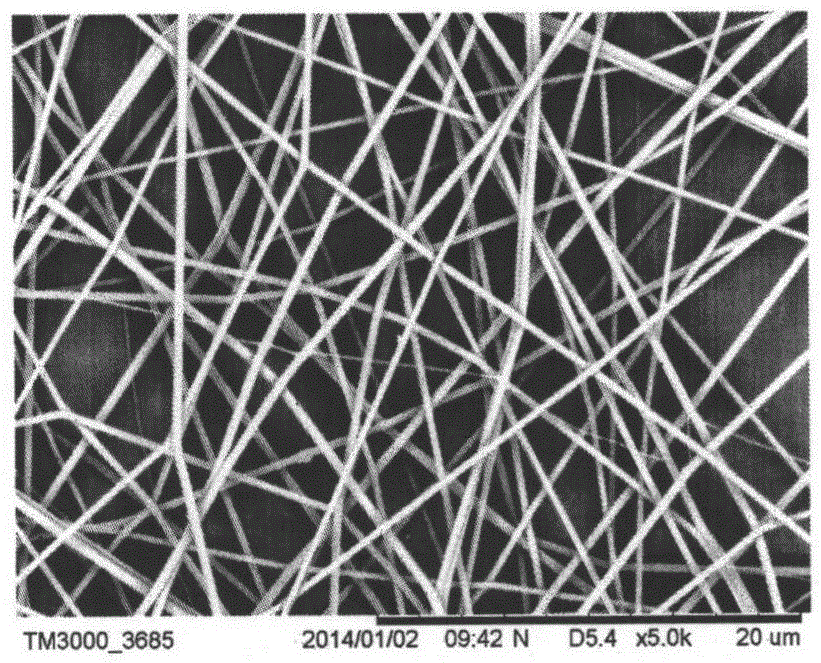

Embodiment 3

[0038] Take by weighing a certain amount of distilled water and glacial acetic acid respectively with electronic balance, be made into mass fraction and be 90% acetic acid aqueous solution, take by weighing 9.475g mass fraction and be 90% acetic acid aqueous solution, add the moxifloxacin hydrochloride powder of 0.025g to it, Stir with a magnetic stirrer to fully dissolve, weigh 0.05g of PEO and 0.45g of CS powder and dissolve in the above solution, continue to stir with a magnetic stirrer for 12h, then oscillate with an ultrasonic wave for 0.5h, and finally stand for 1h for defoaming to obtain a uniform, stable spinning solution.

[0039] Add the above spinning solution into the injector for electrospinning, the spinning voltage is 10kv, the feeding rate is 0.5mL / h, the receiving distance is 20cm, the ambient temperature is 15°C, and the relative humidity is 40%. Spinning 5h.

[0040] Place the prepared chitosan-based drug-loaded composite antibacterial microfiber membrane i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com