Electrochemical synthesis method of silicon carbide nanowire

A technology of silicon carbide nanowires and synthesis methods, which is applied in the preparation of nanomaterials and multidimensional nanomaterials, can solve the problems of low raw material requirements and low energy consumption, and achieve the effects of simple preparation process, high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

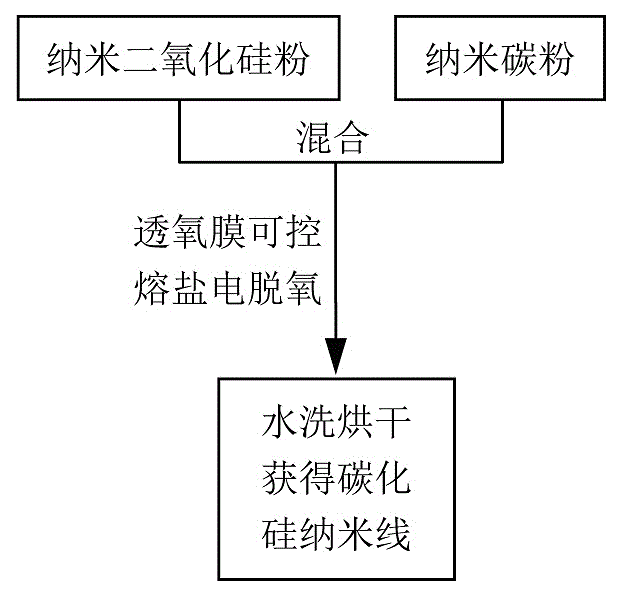

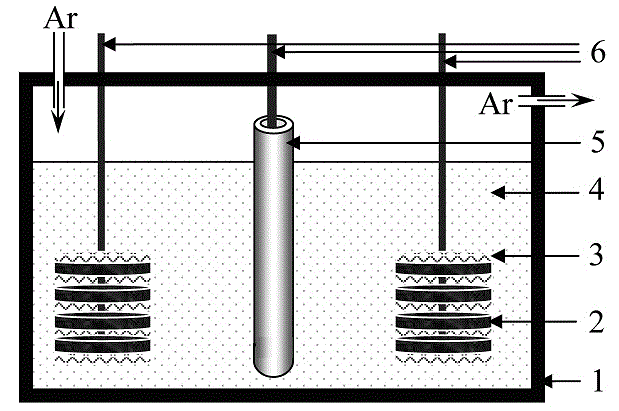

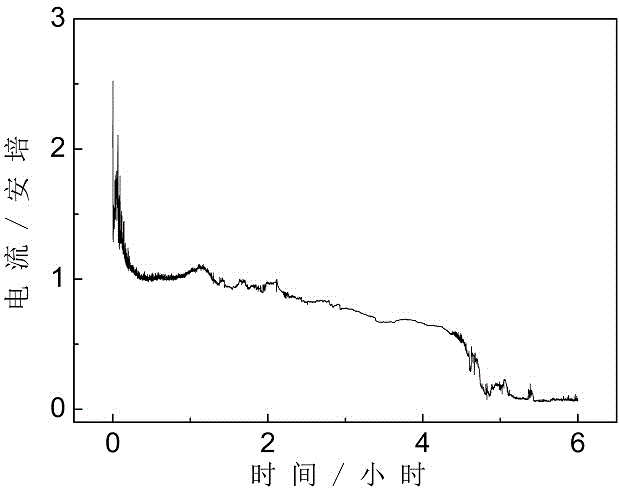

[0027] In this example, figure 1 As shown, the electrochemical synthesis method of silicon carbide nanowires adopts a short-flow preparation process, which includes the following steps: realize weighing 0.5 grams of nanometer carbon dioxide that has been added with a mass fraction of 2% polyvinyl butyral binder and ball-milled uniformly. Silicon oxide / nano-carbon mixture raw material fine powder, wherein nano-silica powder and nano-carbon powder are mixed according to the molar ratio of stoichiometric ratio Si:C = 1:1, and the mixed fine powder is pressed under a pressure of 15 MPa For a single round flake 2. Then use foamed nickel 3 to wrap the pressed sheet in layers and wrap it with iron-chromium-aluminum wire to make a cathode, and use iron-chromium-aluminum wire 6 to draw it as an electrode lead, such as figure 2 As shown, the corundum crucible 1 is used as the electrolytic reaction vessel to avoid the introduction of carbon pollution into the vessel; the pressed sheet ...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, especially in that:

[0031] In this example, the nano-silica / nano-carbon powder mixture powder was added into 2 wt% polyvinyl butyral binder and ball-milled to make it uniform. Then take 0.5 gram of mixed fine powder and press it into circular flakes under the condition of 12 MPa. Wrap the compressed sheet with nickel foam 3 and wrap it with iron-chromium-aluminum wire 6 to make a nano-silica / nano-carbon powder cathode. The prepared cathode is placed in the molten salt electrolytic cell. The placement method can be divided into two cathodes connected in parallel or a single cathode containing multiple precursor sheets. An electrode assembled with an oxygen-permeable zirconia membrane tube with a molar ratio of 8% yttrium oxide is used as an anode system 5 to analyze pure anhydrous CaCl 2 It is a molten salt electrolyte 4, a stainless steel crucible 1 is a reaction vessel, high-purity argon is used as a protective...

Embodiment 3

[0033] This embodiment is basically the same as the previous embodiment, and the special features are:

[0034] In the present embodiment, take 1.0 gram and add the nano-silica / nano-carbon mixture raw material fine powder of 1.5% polyvinyl butyral binder and ball mill uniformly, the fine powder is mixed at 12 MPa Pressed into round flakes under the same conditions. Wrap the compressed sheet with nickel foam 3 and wrap it with iron-chromium-aluminum wire 6 to make a nano-silica / carbon cathode. Place the prepared cathode in the molten salt electrolytic cell. To analyze pure anhydrous CaCl 2 It is a molten salt electrolyte 4, the corundum crucible 1 is a reaction vessel, and high-purity argon is used as a protective gas to perform electrolysis in a sealed resistance furnace. The temperature is selected as 1000°C, the electrolysis voltage is 4.0 volts, and the electrode assembled with the oxygen-permeable membrane tube is used as the anode system. After 10 hours of electrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com