Nanoporous network fibers prepared by high-voltage electrospinning and their applications

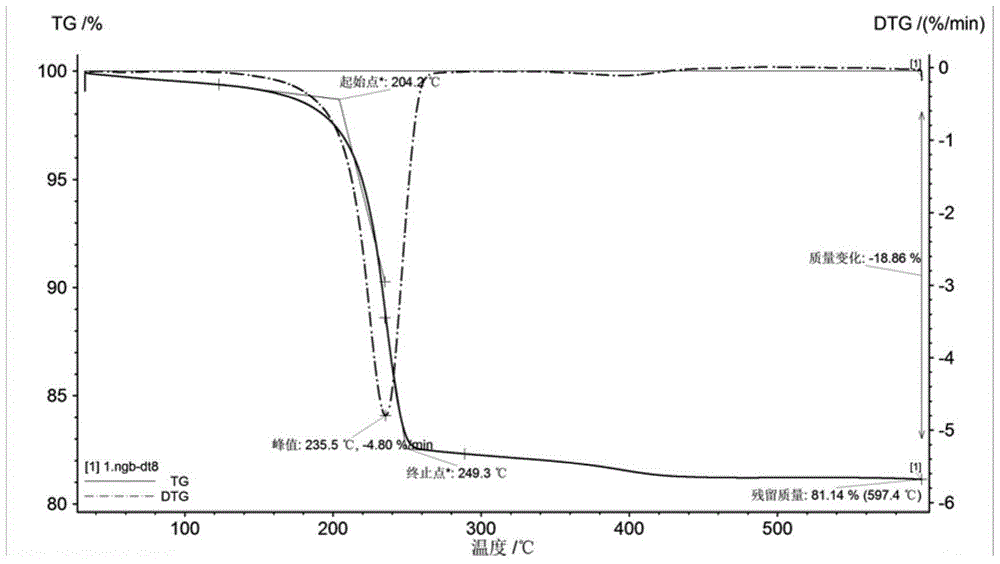

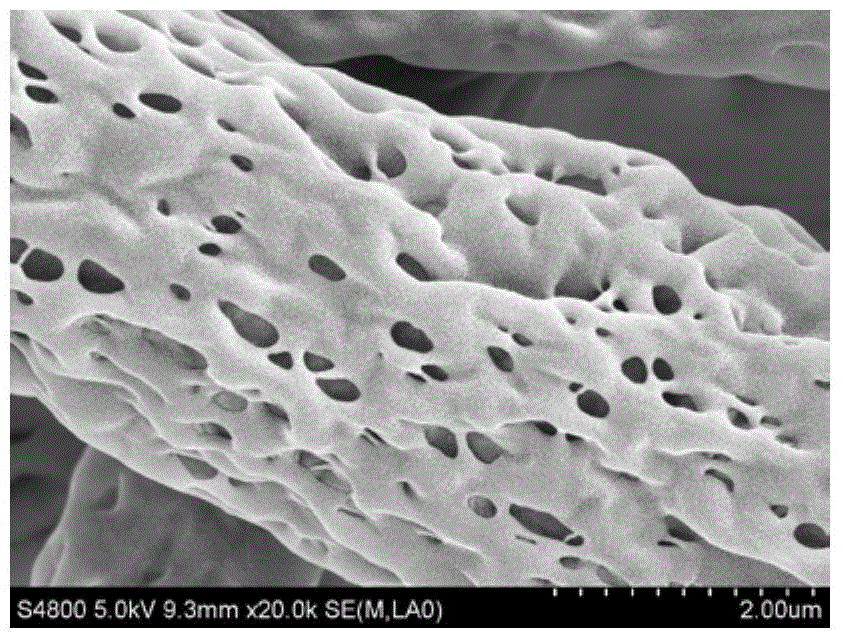

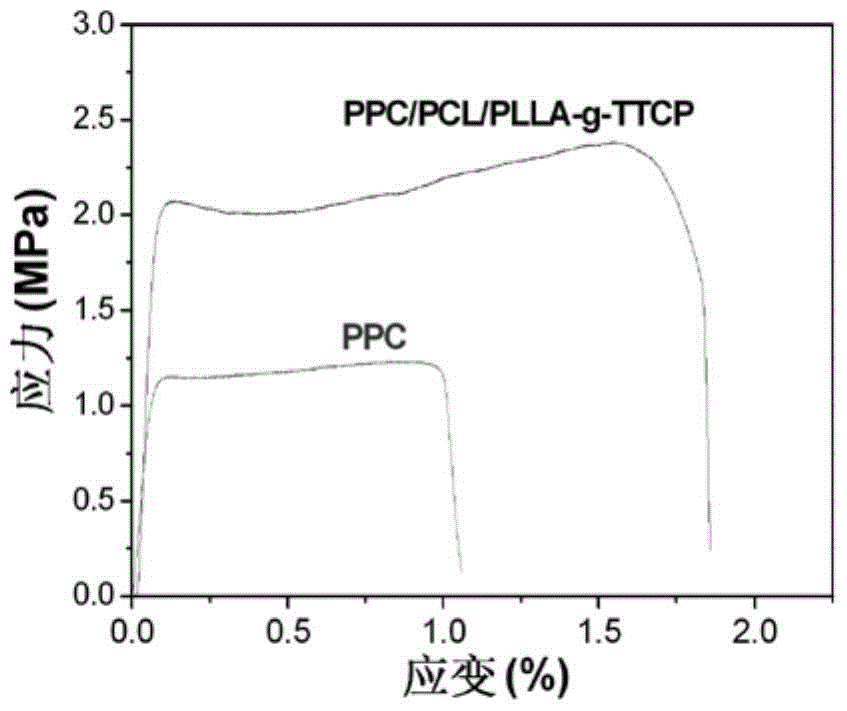

A high-voltage electrospinning and nanofiber technology, which is applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of unfavorable mass industrial production, increase of specific surface area of fiber support, unfavorable calcium salt deposition, etc., and achieve good Biodegradability, good biocompatibility, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First add TTCP to 40ml of toluene and ultrasonically treat it until it is fully dispersed, then add L-lactide (L-lactide) and at the same time add 0.2% Sn(Oct) based on the total mass of L-lactide and TTCP 2 , heated up to 110°C for 2 hours, the mass ratio of L-lactide to TTCP was 97.5:2.5, the resulting product was precipitated in petroleum ether at -20°C, filtered by suction, and dried in vacuum; the dried product was placed in a cable Extract with dichloromethane in an extractor until no characteristic peak of the PLLA molecular group can be detected in the extract by nuclear magnetic resonance analysis, and the obtained L-polylactic acid-tetracalcium phosphate is dried in a vacuum oven for later use.

[0043] The viscosity-average molecular weight after vacuum drying in a mass ratio of 40:40:20 is 5×10 4 Polypropylene carbonate with a viscosity average molecular weight of 5×10 4 The polycaprolactone pellets are mixed with L-polylactic acid-tetracalcium phosphate, a...

Embodiment 2

[0045] First add TTCP to 40ml of toluene and ultrasonically treat it until it is fully dispersed, then add L-lactide, and at the same time add 0.3% Sn(Oct) based on the total mass of L-lactide and TTCP 2 , the temperature was raised to 135° C. for 9 hours, and the mass ratio of L-lactide to TTCP was 92.5:7.5. The post-treatment of the obtained product was the same as that in Example 1, and was omitted here.

[0046] The viscosity-average molecular weight after vacuum drying with a mass ratio of 77:15:8 is 6×10 4 Polypropylene carbonate, viscosity average molecular weight is 6×10 4 The polycaprolactone pellets are mixed with L-polylactic acid-tetracalcium phosphate, and 0.15% titanium tetrachloride and 0.15% lithium bromide based on the total mass of the previous three materials, and then added chloroform: ethyl acetate: DMSO is 80: A mixed solution with a concentration of 14% was prepared in a mixed solvent of 3:17; the prepared mixed solution was placed in an electrospinning...

Embodiment 3

[0048] First add TTCP to 50ml of toluene and ultrasonically treat it until it is fully dispersed, then add L-lactide, and at the same time add 0.3% Sn(Oct) based on the total mass of L-lactide and TTCP 2 , the temperature was raised to 120° C. for 7 hours, and the mass ratio of L-lactide to TTCP was 95:5. The post-treatment of the obtained product was the same as in Example 1, and was omitted here.

[0049] The viscosity-average molecular weight after vacuum drying with a mass ratio of 70:20:10 is 6×10 4 Polypropylene carbonate with a viscosity average molecular weight of 1×10 5 The polycaprolactone pellets were mixed with L-polylactic acid-tetracalcium phosphate, and 0.5% titanium tetrachloride based on the total mass of the previous three materials, and then added chloroform: ethyl acetate: DMF with a ratio of 88: 2: 10 A mixed solution with a concentration of 10% is prepared in a mixed solvent; the prepared mixed solution is placed in an electrospinning device connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com