A method for manufacturing a quantum dot-doped solar fluorescent concentrating power generation system

A technology of a power generation system and a manufacturing method, applied in the field of solar power generation, can solve the problems of shortening the service life of solar cells, limiting commercialization, self-absorption of poor energy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

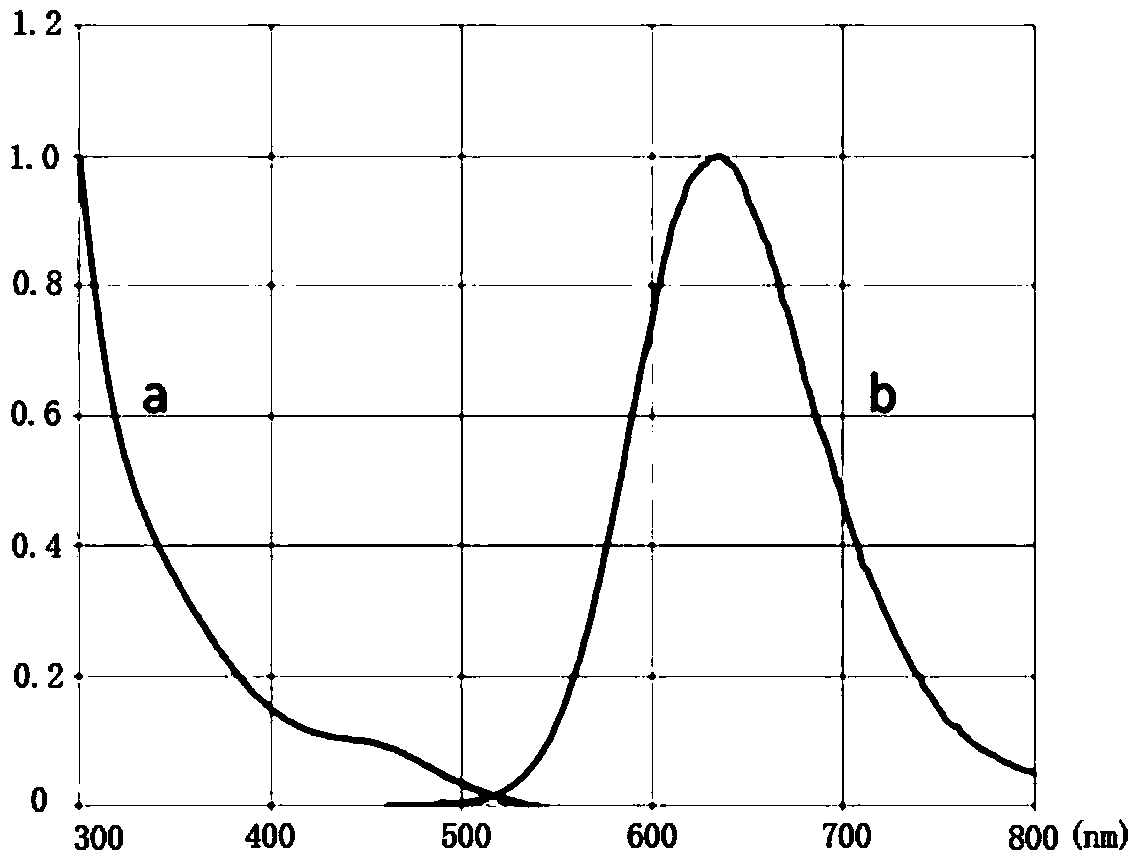

[0037] Inorganic nano-CuInS is selected as fluorescent material 2 (CIS) quantum dots, the required CIS quantum dots are synthesized through the "one-pot reaction method". The outer layer of the CIS quantum dots is covered with a layer of ZnS. Absorbed blue-violet light is converted to broadband red-orange light emission. The synthesized CIS quantum dots are dispersed in n-hexane solution for use, and its characteristic spectrum is as follows figure 1 As shown, a is the absorption spectrum, b is the emission spectrum, and the wavelength difference between the excitation wavelength and the emission wavelength is greater than 180nm.

[0038] The planar optical waveguide is made by bulk polymerization of methyl methacrylate. The specific polymerization process is as follows:

[0039] Measure 20mL of the bulk solution of methyl methacrylate in a conical flask, weigh the white solid of azobisisobutyronitrile and add it to the bulk solution of methyl methacrylate, stir it evenly wi...

Embodiment 2

[0045] Inorganic nano AgInSe is used as fluorescent material 2 Quantum dots, the required AgInSe was synthesized by "one-pot reaction method" 2 Quantum dots, AgInSe 2 The outer layer of quantum dots is wrapped with a layer of ZnSe, and the synthesized AgInSe 2 Quantum dots have the characteristics of broadband blue-violet light absorption and high quantum yield, and can convert the absorbed blue-violet light into broadband red-orange light emission. The synthesized AgInSe 2 Quantum dots are dispersed in n-hexane solution for use.

[0046] The planar fluorescent optical waveguide is manufactured by using polymethyl methacrylate solid particles and fluorescent material powder through physical mixing and high-temperature pressing molding. The specific process is: make fluorescent material into powder, weigh appropriate amount of polymethyl methacrylate solid particles and powdery fluorescent material, mix them uniformly by physical blending method, then transfer them to a spec...

Embodiment 3

[0049] The fluorescent material is inorganic nano CuInTe 2 Quantum dots, the desired CuInTe was synthesized by a "one-pot reaction method" 2 Quantum dots, CuInTe 2 The outer layer of quantum dots is wrapped with a layer of ZnTe, and the synthesized CuInTe 2 Quantum dots have the characteristics of broadband blue-violet light absorption and high quantum yield, and can convert the absorbed blue-violet light into broadband red-orange light emission. The synthesized CuInTe 2 Quantum dots are dispersed in n-hexane solution for use.

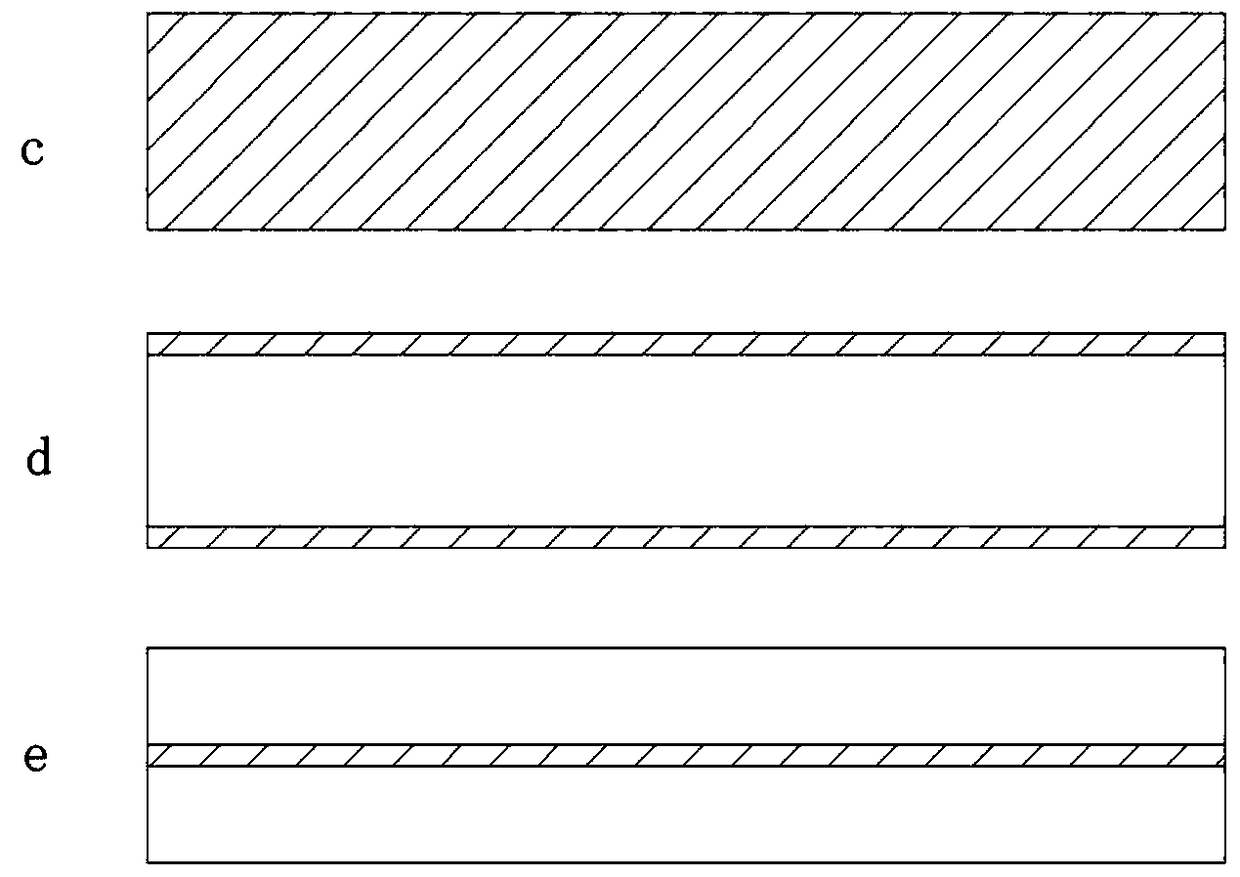

[0050] The planar optical waveguide uses polycarbonate as the matrix, and the upper and lower surface areas of the planar optical waveguide are 10 times the area of its side surfaces. The fluorescent material is sprayed to form a fluorescent film on the upper and lower surfaces of the planar optical waveguide. The composite method is as follows: figure 2 As shown in d, a planar fluorescent lightguide is obtained. The specific process is: uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com