Acrylate modified waterborne polyurethane emulsion and preparation method thereof

A water-based polyurethane and acrylate technology, applied in the field of polymer chemical materials, can solve the problems of low water resistance, poor physical and mechanical properties, and large energy consumption, and achieve the effects of stable product properties, improved mechanical properties, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

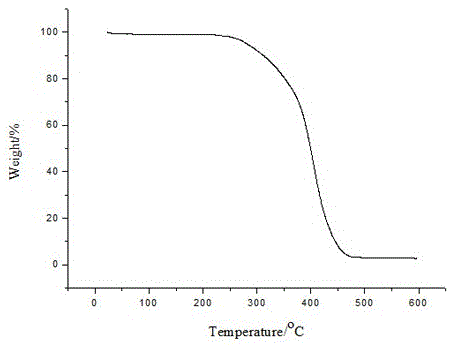

Image

Examples

Embodiment 1

[0027] (1) Add 25 parts of polycarbonate diol with a molecular weight of 2000 into a dry reactor, heat to melt the polycarbonate diol in the reaction bottle, vacuumize at 120°C to remove water for 1 hour, and then lower the temperature To 80°C, add 10 parts of isophorone diisocyanate and 0.1% by mass of dibutyltin dilaurate into the reaction flask, and react under nitrogen protection at 80°C for 2 hours, then add 2 parts of dihydroxypropionic acid to react Obtain prepolymer in 2 hours;

[0028] (2) The reaction is lowered to 70° C., and 5 parts of hydroxypropyl acrylate are added to perform a capping reaction for 2 hours to obtain a polyurethane prepolymer with active double bonds introduced into the main chain;

[0029] (3) After the reaction, the temperature was lowered to 40°C and a total of 15 parts of methyl acrylate and methyl methacrylate were added to reduce the viscosity of the prepolymer, and then 2 parts of triethylamine were added for neutralization reaction for ha...

Embodiment 2

[0032] (1) Add 25 parts of polybutylene adipate diol with a molecular weight of 2000 into a dry reactor, heat to melt the polycarbonate diol in the reaction bottle, and then vacuumize at 120°C to remove water for 1 hour, then lower the temperature to 80°C, add 10 parts of isophorone diisocyanate and 0.1% by mass of dibutyltin dilaurate into the reaction flask, react for 2 hours at 80°C under the protection of nitrogen, and then add 3 parts of Dihydroxypropionic acid was reacted for 2 hours to obtain prepolymer;

[0033] (2) Adding 6 parts of hydroxypropyl acrylate under the protection of nitrogen at 80°C for a capping reaction for 2 hours to obtain a polyurethane prepolymer with active double bonds introduced into the main chain;

[0034] (3) After the reaction, the temperature was lowered to 40°C and a total of 15 parts of methyl acrylate and methyl methacrylate were added to reduce the viscosity of the prepolymer, and then 2 parts of triethylamine were added for neutralizati...

Embodiment 3

[0037] (1) Add 20 parts of polycarbonate diol with a molecular weight of 2000 into a dry reactor, heat to melt the polycarbonate diol in the reaction bottle, vacuumize at 120°C to remove water for 1 hour, and then lower the temperature To 80°C, add 10 parts of hexamethylene diisocyanate and 0.1% by mass of dibutyltin dilaurate into the reaction flask, react under nitrogen protection at 80°C for 2 hours, and then add 2 parts of dihydroxybutyric acid to react Obtain prepolymer in 2 hours;

[0038] (2) The reaction is lowered to 70° C., and 5 parts of pentaerythritol diacrylate are added for a capping reaction for 2 hours to obtain a polyurethane prepolymer with active double bonds introduced into the main chain;

[0039] (3) After the reaction, the temperature was lowered to 40°C and a total of 20 parts of ethyl acrylate and methyl methacrylate were added to reduce the viscosity of the prepolymer, and then 2 parts of triethylamine were added for neutralization reaction for half ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com