High-conductivity graphene fiber and preparation method thereof

A technology of graphene fiber and high conductivity, which is applied in the fields of fiber chemical characteristics, wet spinning method, chemical post-treatment of rayon, etc. It can solve problems such as difficulty in meeting application requirements, unsatisfactory conductivity of graphene fiber, etc., and achieve conductivity improvement , easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

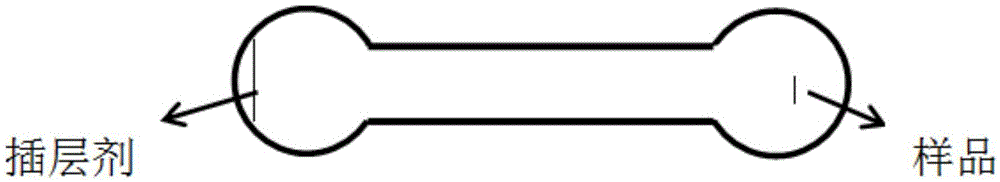

Method used

Image

Examples

Embodiment 1

[0029] (1) 1 g of graphene oxide and 50 g of N,N-dimethylacetamide were mixed, and subjected to ultrasonic treatment at 70 KHz for 1 h at 25° C. to obtain a graphene oxide spinning solution.

[0030] (2) Take the graphene oxide spinning solution obtained in step (1), pass it through a spinning head with an inner diameter of 200 μm at an extrusion speed of 10 mL / h, fully solidify in an ethyl acetate coagulation bath at 25 ° C, and then pass through Collect and dry to obtain graphene oxide fibers.

[0031] (3) Place the graphene oxide fiber obtained in step (2) in a 37% hydroiodic acid aqueous solution, reduce it at 90° C. for 24 hours, wash and dry to obtain the primary graphene fiber.

[0032] (4) Treat the primary graphene fibers obtained in step (3) in an argon atmosphere at 1000° C. for 2 hours to obtain high-quality graphene fibers.

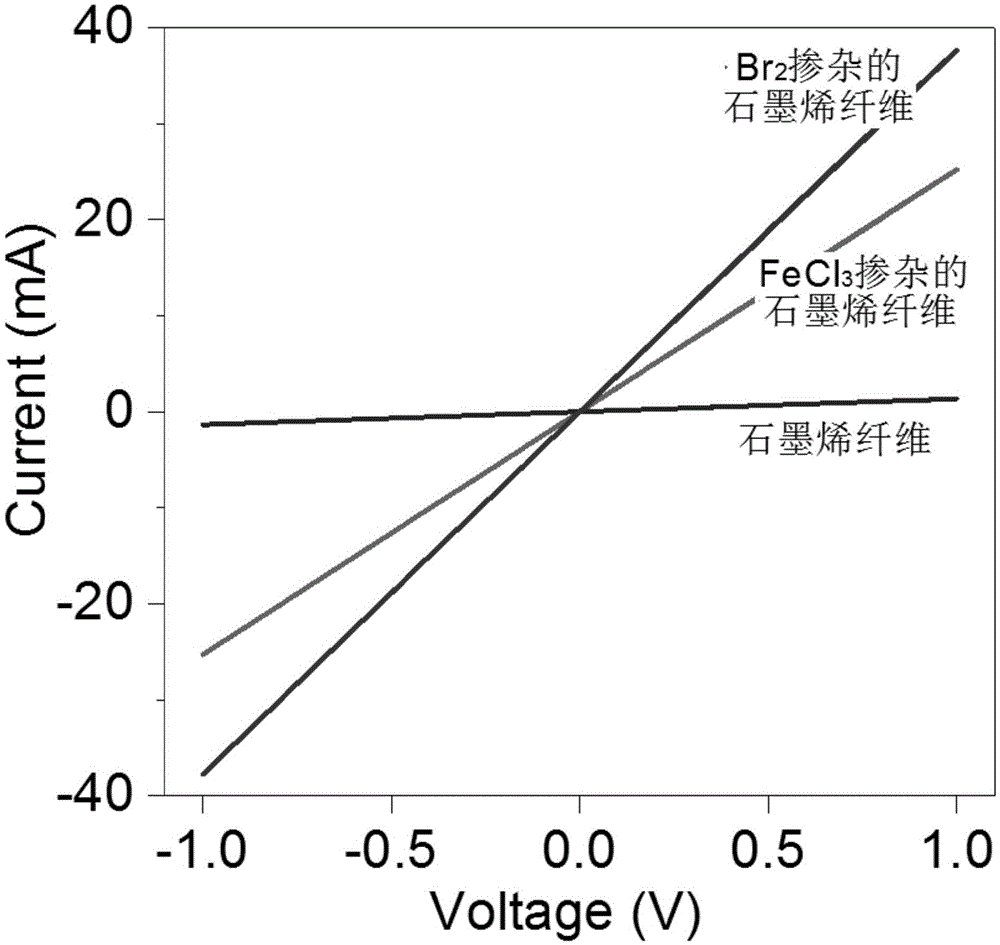

[0033] (5) Place the high-quality graphene fiber obtained in step (4) in a quartz tube, and process it in a bromine vapor for 12h to obtain...

Embodiment 2

[0036] (1) 1 g of graphene oxide and 100 g of dimethyl sulfoxide were mixed, and subjected to ultrasonic treatment at 20° C. at 40 KHz for 1 h to obtain a graphene oxide spinning solution.

[0037] (2) Take the graphene oxide spinning solution obtained in step (1), pass through a spinning head with an inner diameter of 80 μm at an extrusion speed of 1 mL / h, and use n-butanol and ethylene glycol at a volume ratio of 1:1 at 25° C. Fully coagulated in the coagulation bath composed to obtain graphene oxide fibers.

[0038] (3) Place the graphene oxide fiber obtained in step (2) in hydrazine hydrate with a mass fraction of 10%, reduce at 90° C. for 12 hours, wash and dry to obtain primary graphene fiber.

[0039] (4) Treat the primary graphene fibers obtained in step (3) at 2000° C. for 1.5 h in an argon atmosphere to obtain high-quality graphene fibers.

[0040] (5) Place the high-quality graphene fiber obtained in step (4) in a quartz tube, and process it in ferric chloride vapo...

Embodiment 3

[0043] (1) 2g of graphene oxide and 20g of N,N-dimethylacetamide were mixed, and subjected to ultrasonic treatment at 30°C at 40KHz for 2h to obtain a graphene oxide spinning solution.

[0044] (2) Get the graphene oxide spinning solution obtained in step (1), pass through a spinneret with an inner diameter of 300 μm at an extrusion speed of 100 mL / h, and stay in an acetone solid bath at 25° C. for 1 min to become a gel fiber, Graphene oxide fibers are obtained.

[0045] (3) Place the graphene oxide fibers obtained in step (2) in a mixed solvent of hydroiodic acid and trifluoroacetic acid, heat to 90° C., reduce for 1 hour, wash and dry to obtain primary graphene fibers.

[0046] (4) Treating the primary graphene fibers obtained in step (3) at 3000° C. for 1 h in an argon atmosphere to obtain high-quality graphene fibers.

[0047] (5) Place the high-quality graphene fiber obtained in step (4) in a quartz tube, and treat it with metal potassium vapor for 1 h under vacuum condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com