High-temperature-resistant abrasion-resistant non-stick pan coating, preparation method and non-stick pan with same

A non-stick pan and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant and wear-resistant non-stick pan coating and preparation, can solve problems that affect product structure and performance, damage, food foreign matter risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

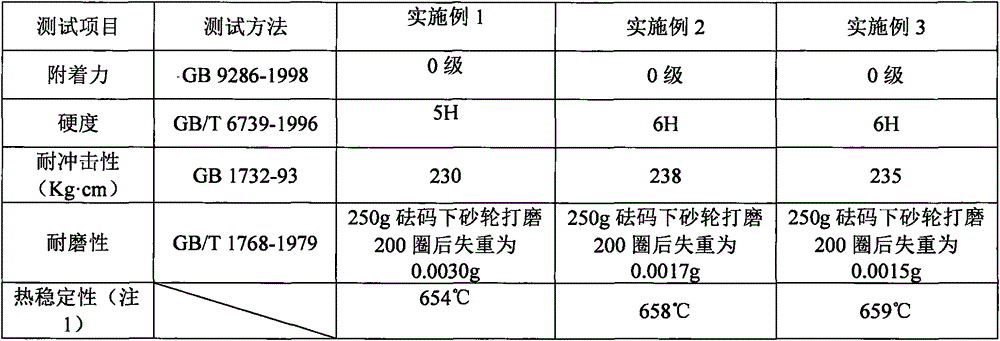

Examples

preparation example Construction

[0018] The invention provides a method for preparing a high-temperature-resistant and wear-resistant non-stick pan coating, which comprises the following steps: 200-300 parts by mass of nickel sulfate, 45-60 parts by mass of sodium citrate, 50-90 parts by mass of ammonium chloride, 60 - 100 parts by mass of sodium sulfite and deionized water are mixed to obtain the first mixed solution; under the action of an external magnetic field, the metal pan substrate is placed in the first mixed solution for electrochemical nickel plating, and the pH value is adjusted to 8.0-10.0, drying, the temperature of the first mixed liquid is 40-60 ° C, the control current is 50-80A; 80-120 parts by mass of polyarylether nitrile ketone, 1-5 parts by mass of silane coupling agent KH792 Mix with 3-8 parts by mass of nano-silicon tetranitride, stir, and obtain mixture A after electron beam pre-irradiation; spray the mixture A on the inner surface of the metal pan base to obtain a high-temperature-res...

Embodiment 1

[0039] (1) The metal pot body is placed in 20 mass parts of sodium silicate, 40 mass parts of potassium hydroxide, 20 mass parts of potassium carbonate, 20 mass parts of citric acid fatty acid glyceride, 1 mass part of ethylenediamine polyoxyethylene polyoxygen Propylene block polyether, 20 parts by mass of sodium sulfate, 2 parts by mass of disodium edetate, 20 parts by mass of sodium percarbonate, 15 parts by mass of sodium dodecyl alcohol polyoxyethylene ether sulfate, 600 parts by mass of deionized water In the mixed solution formed by mixing, ultrasonic vibration treatment was performed for 30 minutes. The temperature of the mixed solution was 70° C., then moved into 50° C. hot water for ultrasonic oscillation treatment for 60 minutes, and rinsed with water after taking it out.

[0040] (2) Place the inner surface of the metal pot body in a mixed solution mixed with 200 parts by mass of nickel sulfate, 60 parts by mass of sodium citrate, 50 parts by mass of ammonium chlori...

Embodiment 2

[0044] (1) The metal pot body is placed in 50 mass parts sodium silicate, 30 mass parts potassium hydroxide, 20-50 mass parts potassium carbonate, 15 mass parts citrate fatty acid glyceride, 5 mass parts ethylenediamine polyoxyethylene Polyoxypropylene block polyether, 20 parts by mass of sodium sulfate, 10 parts by mass of disodium edetate, 5 parts by mass of sodium percarbonate, 20 parts by mass of sodium lauryl alcohol polyoxyethylene ether sulfate, 800 parts by mass of In the mixed solution formed by mixing ionic water, ultrasonic vibration treatment was performed for 90 minutes. The temperature of the mixed solution was 50°C, and then moved into 80°C hot water for ultrasonic oscillation treatment for 30 minutes. After taking it out, rinse it with water.

[0045] (2) Place the inner surface of the metal pot body in a mixed solution mixed with 300 parts by mass of nickel sulfate, 45 parts by mass of sodium citrate, 90 parts by mass of ammonium chloride, 60 parts by mass of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com