Nano lithium manganite loaded carbon material cathode catalyst used for oxygen reduction of air electrode as well as preparation method and application of nano lithium manganite loaded carbon material cathode catalyst

A nano-lithium manganate, cathode catalyst technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology and other directions, can solve the problem of reducing the cycle stability of lithium-air batteries, reducing battery charge and discharge overpotential, expensive Price cost and other issues, to achieve the effect of improving charge and discharge efficiency, conducive to uniform dispersion and distribution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

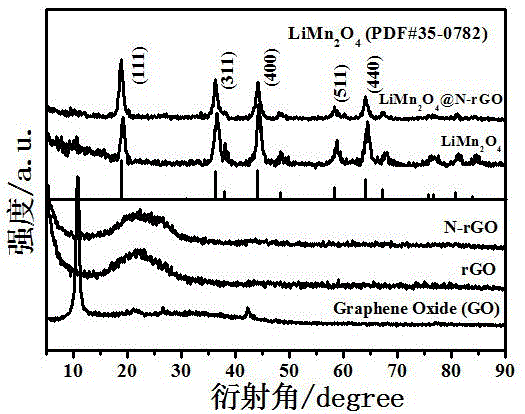

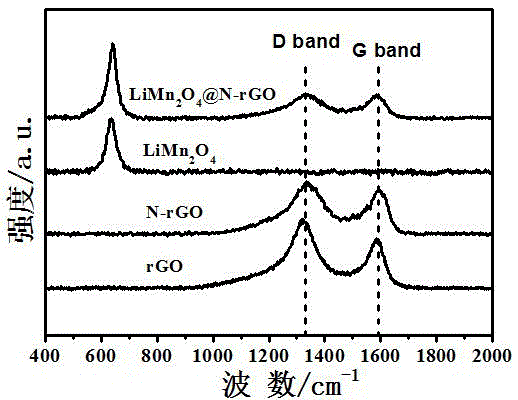

[0031] Preparation of nitrogen-doped reduced graphene:

[0032] (1) Preparation of reduced graphene catalyst

[0033] Add 1.0g of natural flake graphite powder and 0.5g of sodium nitrate to 70mL of concentrated sulfuric acid, stir magnetically for 3 hours, place it in an ice-water bath, add 1.0g of potassium permanganate and stir for 2 hours, then add 100mL of distilled water at 98°C for dilution , then add 7mL of 30% hydrogen peroxide until the color of the solution turns bright yellow, filter while hot, and wash the filter cake with 5% HCl solution until it is washed with BaCl 2 Detection of SO in the filtrate 4 2- Existence, graphene oxide was obtained after freeze-drying.

[0034] Put 100mg of graphene oxide in a horizontal electric tube furnace, under the protection of argon, at 10°C min -1 The heating rate is raised to 900°C, and the flow rate of the inert gas is controlled to 50mLmin -1; When the temperature reaches 900°C, close the argon gas valve, pass in ammonia...

Embodiment 2

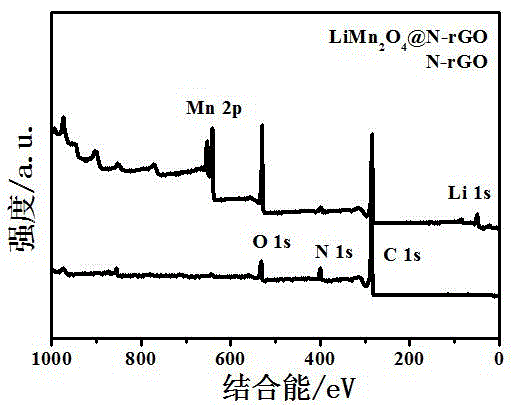

[0040] Preparation of lithium manganate-supported nitrogen-doped reduced graphene:

[0041] (1) Preparation of lithium manganate-supported nitrogen-doped reduced graphene catalyst

[0042] Ultrasonic disperse 60 mg of the nitrogen-doped reduced graphene prepared in Example 1 in 60 mL of ethanol and deionized water with a volume ratio of 1:1, and then add 0.168 g of LiOH and 0.316 g of KMnO 4 After stirring at room temperature for 2 hours, the above solution was poured into an 80mL polytetrafluoroethylene reactor, and reacted at a constant temperature of 180°C for 5 hours. After the reaction was completed, it was naturally cooled to room temperature, and the reaction solution was subjected to suction filtration, washing, and freeze-drying for 12 hours to obtain the Nano-lithium manganese oxide supports nitrogen-doped reduced graphene cathode catalyst, and the loading capacity of lithium manganate prepared by the method is 75wt%. At the same time, the same experimental procedur...

Embodiment 3

[0052] Example 3 Preparation of lithium manganate-supported nitrogen-doped carbon nanotubes:

[0053] The preparation steps of the lithium manganate-supported nitrogen-doped carbon nanotube catalyst in this example are basically the same as in Example 1, the difference is that the carbon material used in this example is a commercial nanotube, and the manufacturer is Shenzhen Nanoport Carbon Material Co., Ltd. .

[0054] The air electrode preparation and lithium-air battery assembly steps in this example are basically the same as those in Example 1, except that the cathode catalyst used in this example is lithium manganate-supported nitrogen-doped carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com