Drug-loaded polymer/calcium-phosphorus composite coating and preparation of degradable magnesium-based intraosseous implants

A technology of polymer coating and composite coating, which is applied in coating, metal material coating technology, medical science, etc., can solve the problems of ineffective drug loading, delay corrosion and degradation rate, reduce cost, and promote bone the effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

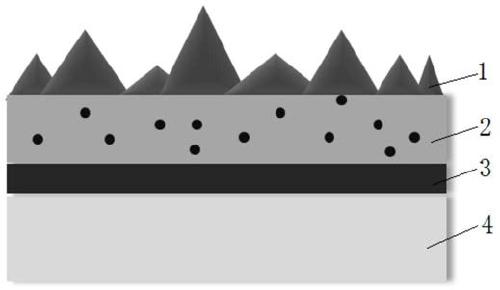

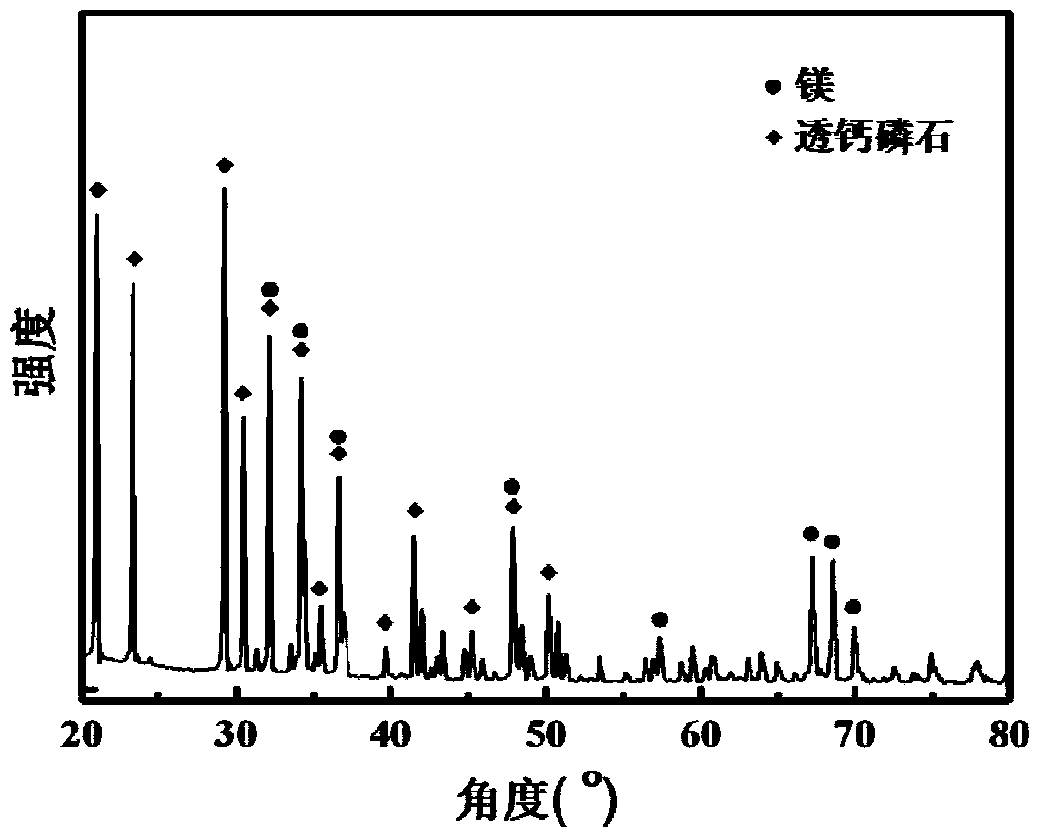

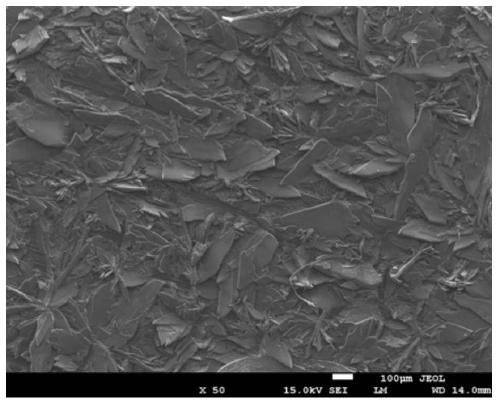

[0050] A degradable polymer carrier for drug loading and a bioactive calcium-phosphorus composite coating were prepared on the surface of pure Mg. figure 1 , including a magnesium substrate 4 , a fluoride film 3 , a biodegradable polymer coating 2 and a bioactive calcium-phosphorus coating 1 . When preparing, first make pure magnesium into The samples were polished with 320-mesh, 1200-mesh and 3000-mesh water sandpaper in turn. Ultrasonic cleaning with absolute ethanol and acetone for 10 min, respectively, and drying. Soak the sample in 40% HF solution at room temperature for 24 hours, wash it with deionized water and absolute ethanol successively, and dry it. Take polytrimethylene carbonate (PTMC) with a weight-average molecular weight of 80000-100000, dissolve it in ethyl acetate solvent at a ratio of 8wt.%, and uniformly coat polytrimethylene carbonate on the fluorinated The surface of pure magnesium was treated, and the pure magnesium coated with polytrimethylene carbo...

Embodiment 2

[0052] A degradable polymer carrier for drug loading and a bioactive calcium-phosphorus composite coating were prepared on the surface of AZ31 (Mg-Al series) alloy. Firstly, the AZ31 magnesium alloy is made into The samples were polished with 320-mesh, 1200-mesh and 3000-mesh water sandpaper in turn. Ultrasonic cleaning with absolute ethanol and acetone for 10 min, respectively, and drying. The sample was soaked in a 40% HF solution in a water bath at a constant temperature (20°C) for 14 hours, washed with deionized water and absolute ethanol successively, and dried. Take racemic polylactic acid (PDLLA) with a weight-average molecular weight of 100000-150000, dissolve it in ethyl acetate solvent at a ratio of 6wt.%, and dissolve paclitaxel at a ratio of 2wt.%. The polylactic acid solution of paclitaxel drug is evenly coated on the surface of the fluorinated magnesium alloy, and the magnesium alloy coated with the paclitaxel-loaded polylactic acid coating is placed in a vacu...

Embodiment 3

[0054] A degradable polymer carrier for drug loading and a bioactive calcium-phosphorus composite coating were prepared on the surface of Mg-Nd-Zn-Zr alloy. Firstly, the Mg-Nd-Zn-Zr magnesium alloy is made into The samples were polished with 320-mesh, 1200-mesh and 3000-mesh water sandpaper in turn. Ultrasonic cleaning with absolute ethanol and acetone for 10 min, respectively, and drying. The sample was soaked in a 20% HF solution in a water bath at a constant temperature (20°C) for 8 hours, washed with deionized water and absolute ethanol successively, and dried. Take polylactic acid-glycolic acid copolymer (PLGA) with a weight average molecular weight of 80000-100000, dissolve it in ethyl acetate solvent at a ratio of 8wt.%, and dissolve paclitaxel at a ratio of 2wt.%. The PLGA solution mixed with paclitaxel is evenly coated on the surface of the fluorinated magnesium alloy, and the magnesium alloy coated with the PLGA coating is placed in a vacuum drying oven at 35°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com