Method for preparing high-purity magnesium fluoride by using magnesite

A pure magnesium fluoride and magnesite technology, applied in magnesium fluoride, magnesium halide and other directions, can solve the problems of high cost of high-purity magnesium compound raw materials, high requirements for equipment corrosion resistance, incomplete magnesium ion precipitation, etc., and achieve low cost. , The effect of low equipment requirements and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

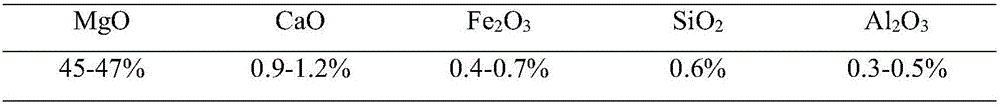

[0021] As shown in Table 1, it is the chemical composition analysis result of the magnesite raw material used in the embodiment of the present invention. After the magnesite is calcined at high temperature, the weight loss is constant, the MgO content is 90%, and the calcium oxide content is 2.1%. This is calcined magnesite The amount of ore added and the ammonium salt used for calcium removal provide the basis.

[0022] Table 1. The used magnesite raw material chemical composition of the present invention

[0023]

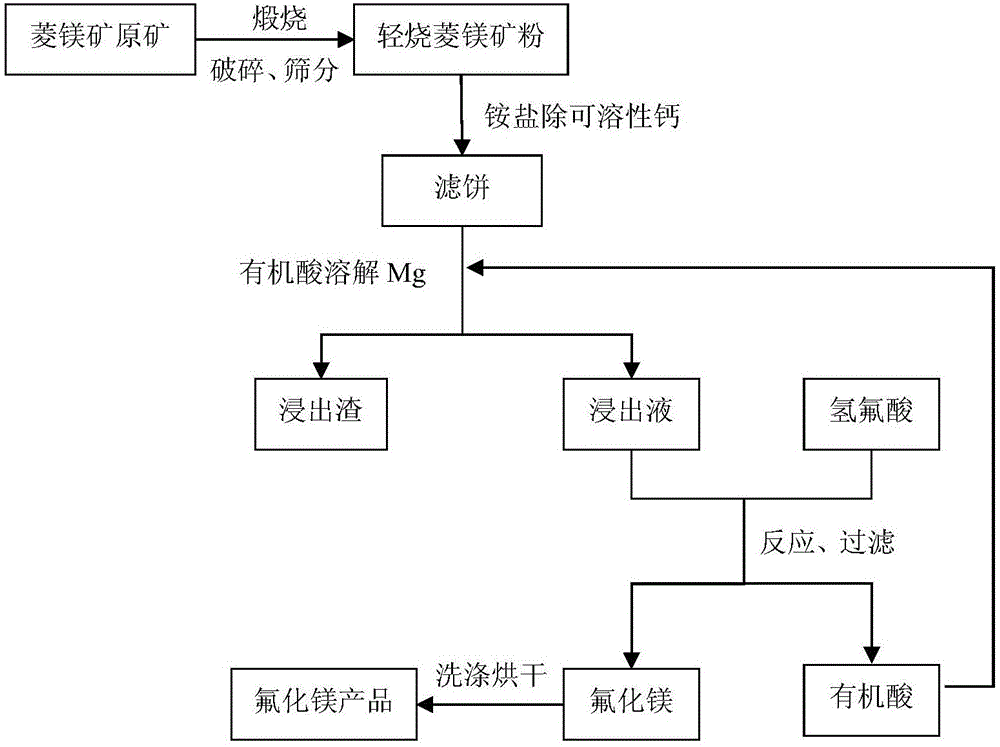

[0024] Prepare high-purity magnesium fluoride, operate according to the following steps (technical process of the present invention is as follows figure 1 shown):

[0025] 1) Using the aforementioned magnesite as raw material, calcining at 800-1200°C for 0.5-2 hours to obtain light-burned magnesia mixture, and then crushi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com