Conversion reaction-based magnesium battery with high energy density

A high energy density, magnesium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited lithium ion concentration, inability to drive conversion reactions, limited battery specific capacity, etc., to improve cycle performance and safety. performance, avoiding the hidden danger of battery short circuit, and broadening the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The manufacturing method of the magnesium battery of this invention is demonstrated below.

[0035] Preparation of the positive electrode: In one example, after uniformly mixing at least one of the above-mentioned positive electrode materials (such as commercial fluoride or sulfide), conductive carbon material, binder, and solvent, coat it on the current collector, and dry it. A positive electrode for a magnesium battery is prepared. The mass ratio of the positive electrode material, the conductive carbon material and the binder may be 8:1:1, 7:2:1 or 6:2:2. Conductive carbon materials include, but are not limited to, Super P, carbon black, and the like. Binders include, but are not limited to, polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE), sodium carboxymethylcellulose (CMC), and the like. Solvents include, but are not limited to, N-methylpyrrolidone (NMP), tetrahydrofuran (THF), and the like. Current collectors include, but are not limited to, carb...

Embodiment 1

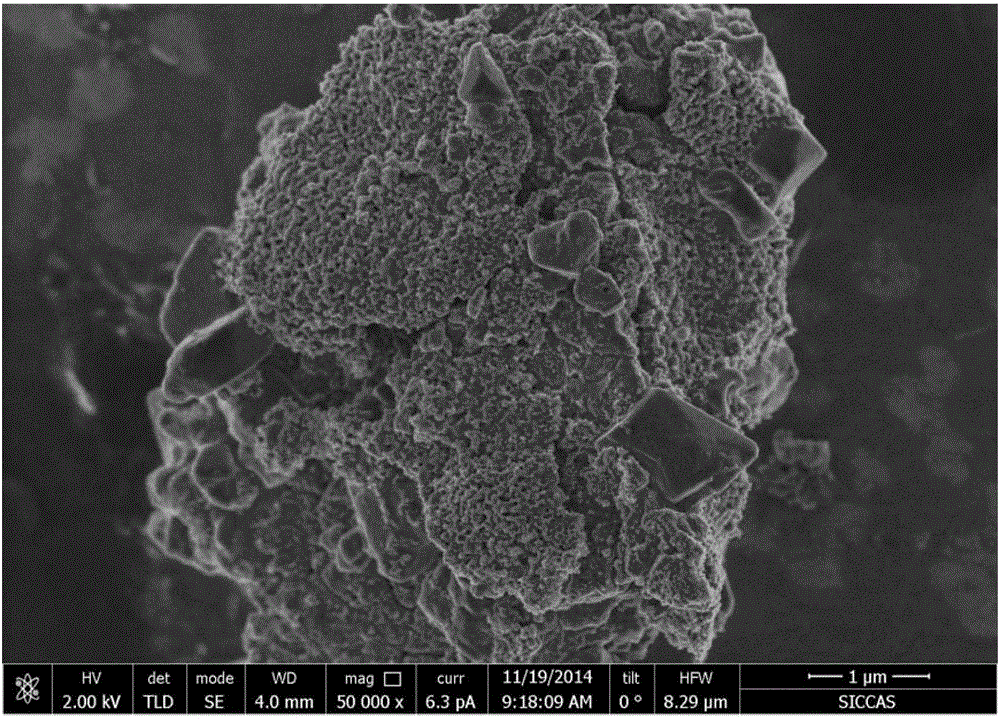

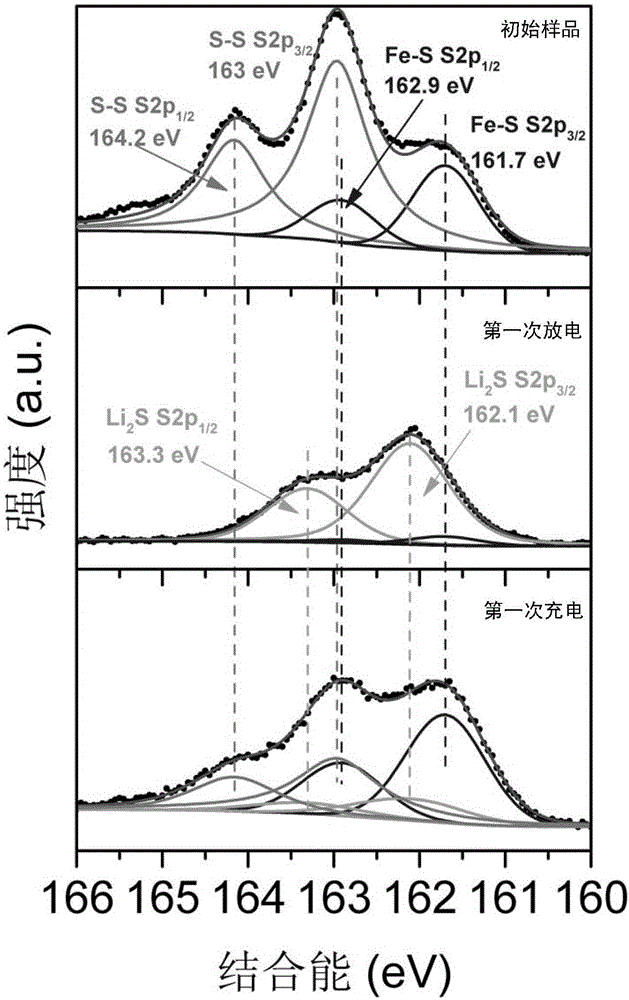

[0041] 1) FeS 2 Preparation of cathode materials

[0042] Weigh commercial FeS 2 Powder sample 24mg, Super P 6.8mg, put into the mortar and grind for 30min. Then add 68 μl of PVDF and NMP solutions with a concentration of 20 mg / μl, grind and stir for 10 to 15 minutes. Spread the black paste evenly on 12 pieces with an area of 50mm 2 carbon paper and dried in a vacuum oven at 80°C for 12 hours. The carbon paper loaded with the active substance after vacuum drying was weighed again, and packed into a glove box.

[0043] 2) Preparation of lithium-magnesium double-salt electrolyte

[0044] Put lithium borohydride and magnesium borohydride into an argon glove box. Add 327mg of lithium borohydride and 54mg of magnesium borohydride into 10ml of diethylene glycol dimethyl ether solvent, and magnetically stir for 24 hours to fully dissolve the solute.

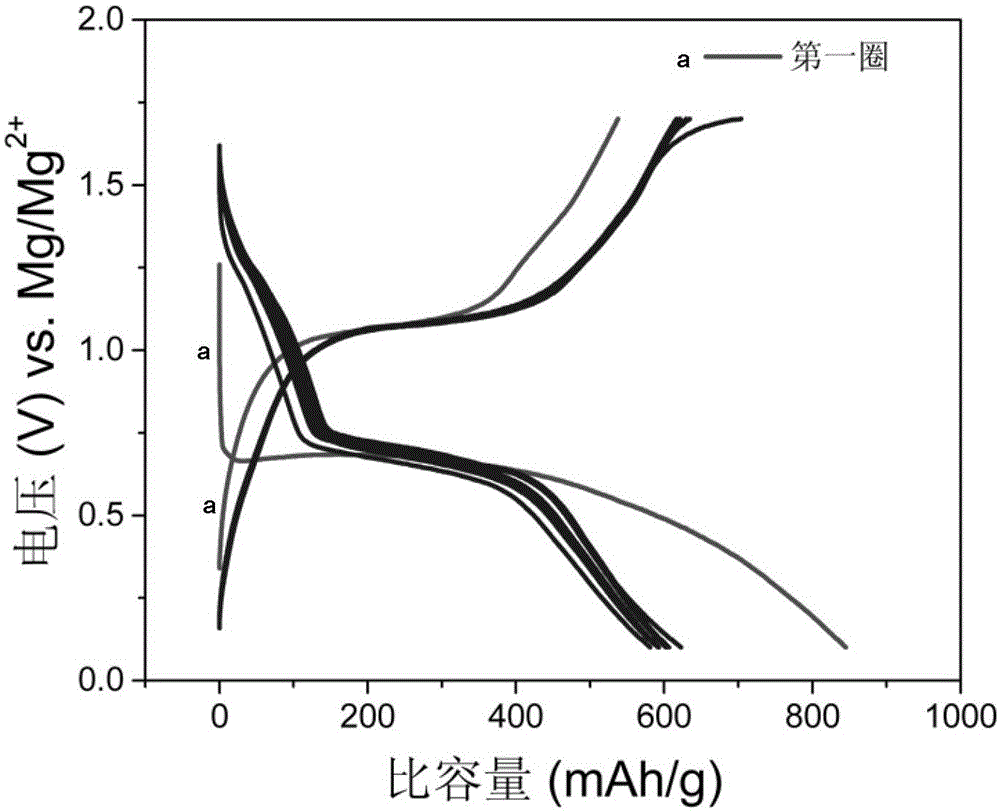

[0045] 3) Battery assembly and testing

[0046] The 2025 button battery was assembled in an argon glove box with water value...

Embodiment 2

[0048] 1) Preparation of FeS cathode material

[0049] Weigh 24 mg of FeS powder sample and 6.8 mg of Super P, and grind them in a mortar for 30 min. Then add 68 μl of PVDF and NMP solutions with a concentration of 20 mg / μl, grind and stir for 10 to 15 minutes. Spread the black paste evenly on 12 pieces with an area of 50mm 2 carbon paper and dried in a vacuum oven at 80°C for 12 hours. The carbon paper loaded with the active substance after vacuum drying was weighed again, and packed into a glove box.

[0050] 2) Preparation of lithium-magnesium double-salt electrolyte

[0051] Put lithium borohydride and magnesium borohydride into an argon glove box. Add 327mg of lithium borohydride and 54mg of magnesium borohydride into 10ml of diethylene glycol dimethyl ether solvent, and magnetically stir for 24 hours to fully dissolve the solute.

[0052] 3) Battery assembly and testing

[0053] The 2025 button battery was assembled in an argon glove box with water value and oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com