Absorbable intravascular stent and preparation method thereof

A vascular stent and metal stent technology, applied in the field of medical devices, can solve the problems of easy to produce chronic inflammation, easy to produce block, high vascular endothelial hyperplasia rate, avoid blood perfusion syndrome, good biocompatibility, anti- good corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A preparation method of the above-mentioned absorbable vascular stent, comprising the steps in turn:

[0054] Step 1, preparation of degradable metal stent frame;

[0055] The degradable metal stent body can be prepared by the following methods: braiding a single wire of a degradable metal material, such as a magnesium alloy; or laser cutting a tube of a degradable metal; or using a molding method; or using 3D printed.

[0056]Step 2, preparation of degradable polymer spray coating slurry, weighing raw materials according to the above-mentioned proportion of degradable polymer coating components, dissolving the raw materials in an organic solvent, heating to 70-90°C while stirring and mixing, and keeping warm 5-10min, after cooling, the degradable polymer spray slurry is obtained; preferably, the stirring and mixing is ultrasonic stirring and mixing; the organic solvent is preferably tetrahydrofuran or acetone; more preferably, the frequency of the ultrasonic treatment...

Embodiment 1

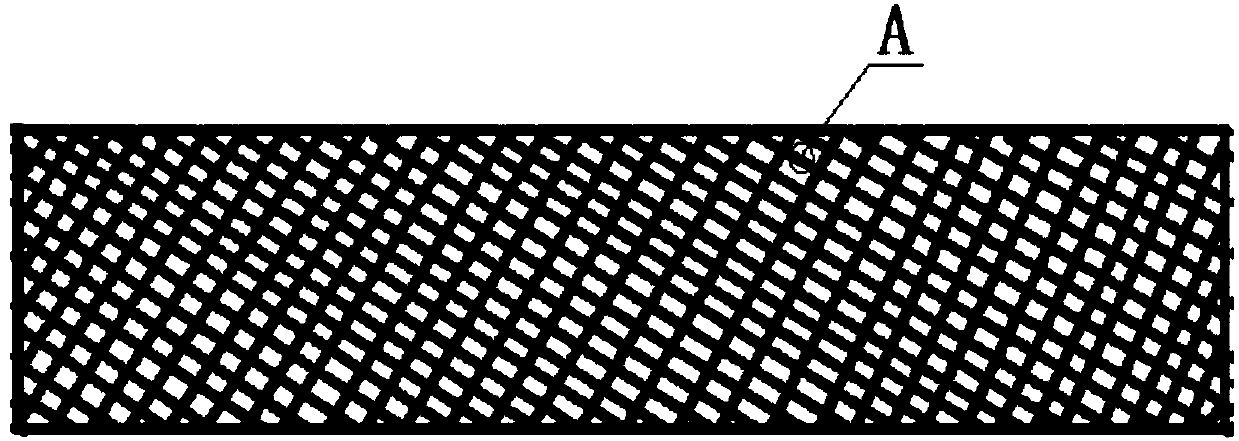

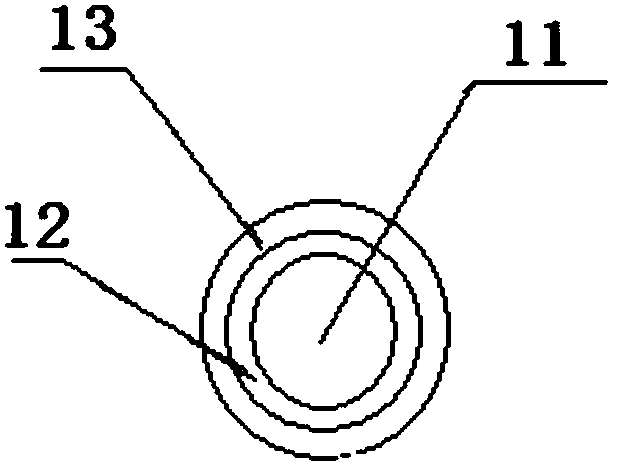

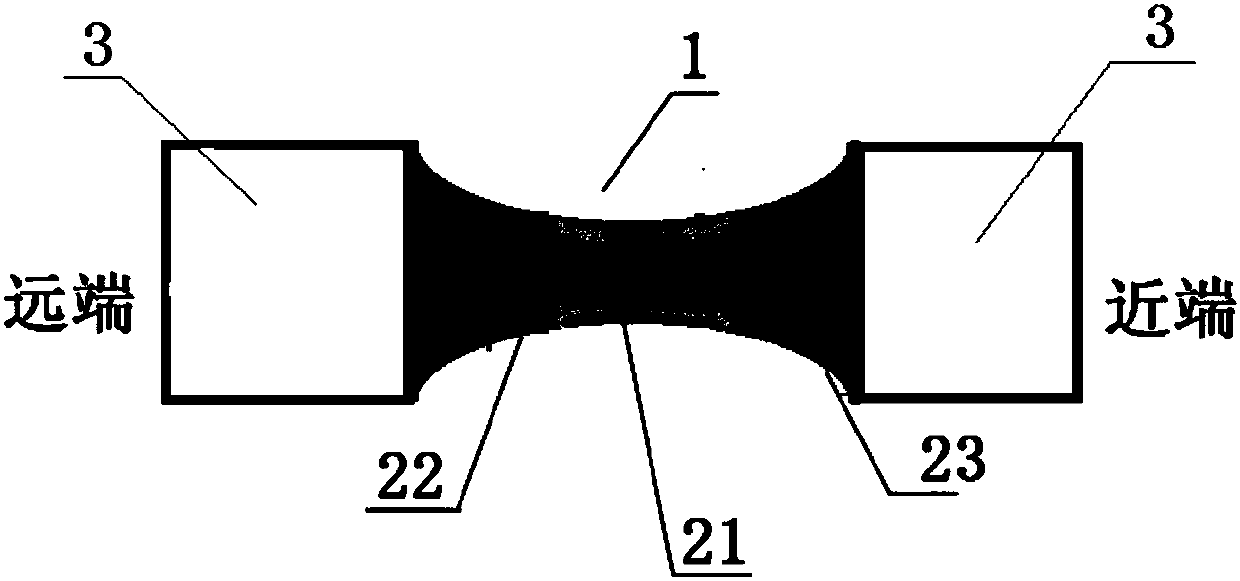

[0063] The absorbable vascular stent prepared in this embodiment includes: a cylindrical mesh-shaped degradable metal stent body, and a degradable polymer coating arranged on the surface of the mesh wire of the cylindrical mesh-shaped degradable metal stent body, that is, to form The mesh surface of the cylindrical mesh degradable metal stent body is covered with a layer of degradable polymer coating, wherein the degradable metal is magnesium alloy WE43, and the composition of the degradable polymer coating is PLGA75: 25. The preparation method is as follows:

[0064] (1) The cylindrical net-like degradable metal stent body is braided by a magnesium alloy WE43 single wire, with a diameter of 1 mm and a length of preferably 10 mm.

[0065] (2) Weigh 1g PLGA 75:25, dissolve it in 10mL tetrahydrofuran, heat it to 80°C under nitrogen condition while ultrasonically stirring and mixing, and keep it warm for 8 minutes. The frequency is 100KHz, the time is 30min, and the degradable ...

Embodiment 2

[0070] The absorbable vascular stent prepared in this embodiment includes: a cylindrical mesh-shaped degradable metal stent body, and a degradable polymer coating arranged on the surface of the mesh wire of the cylindrical mesh-shaped degradable metal stent body, that is, to form The mesh surface of the cylindrical mesh degradable metal stent body is covered with a layer of degradable polymer coating, and the surface of the degradable polymer coating is coated with a phosphorylcholine layer; wherein, the degradable metal is magnesium alloy WE43, the composition of the degradable polymer coating is 80wt% PLGA 75:25, 8wt% chitosan, 6wt% polyglycolic acid, 6wt% polylactic acid, the molecular weight of polyglycolic acid (PGA) is 100,000, Polylactic acid (PLA) has a molecular weight of 100,000. The preparation method is as follows:

[0071] (1) The cylindrical net-like degradable metal stent body is braided with a magnesium alloy WE43 single wire, with a diameter of 1 mm and a len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com