Preparation method of TiO2 nanometer tube loaded bimetallic catalyst

A bimetallic catalyst and nanotube technology, applied in the field of catalysis, can solve the problems of complex preparation process, high equipment requirements, corrosion equipment, etc., and achieve the effect of simple equipment process, wide light response range, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

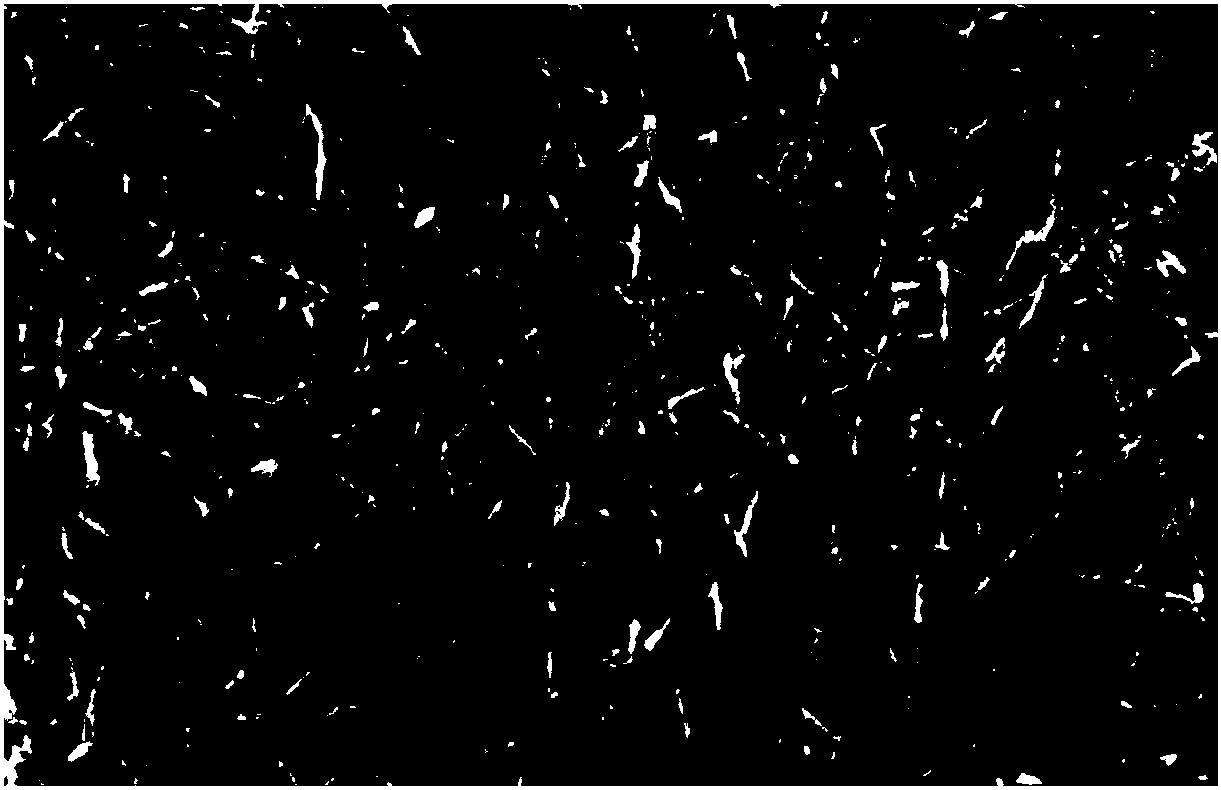

[0041] 1gTiO 2 The powder was dissolved in 25mL of 10M concentrated NaOH solution, ultrasonically dispersed for 30min, transferred to the reactor, and reacted in an oven at 160°C for 8h. The product was washed with deionized water, then soaked in 0.1M hydrochloric acid solution for 12h, then washed with deionized water to neutrality, then dried in an oven at 80℃ for 15h, and calcined in a muffle furnace at 400℃ for 6h to obtain TiO 2 Nanotubes: The length of nanotubes can reach 2-5μm, and the tube diameter is 10-20nm.

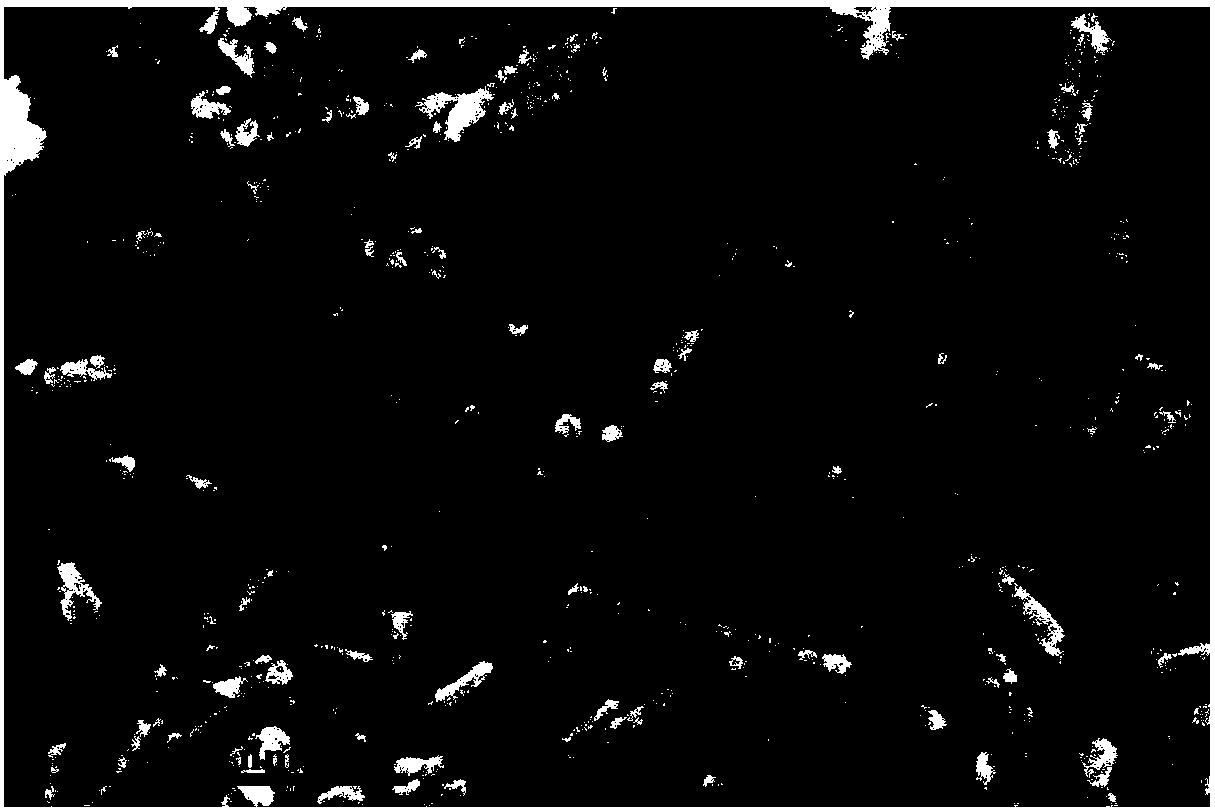

[0042] Weigh the prepared TiO 2 0.2000g of nanotubes, dissolved in 24ml of deionized water, add 0.0422g (0.1747mmol) of copper nitrate and 0.0549g (0.1888mmol) of nickel nitrate to the solution, stir and disperse uniformly, add 3mL of 25% mass fraction dropwise within 3min Ammonia water, magnetic stirring and immersion for 24h. Centrifuge the solution, remove the supernatant, transfer to a round bottom flask with 16mL deionized water, stir well, add 0.0700g NaBH 4...

Embodiment 11

[0053] 1gTiO 2 The powder was dissolved in 25mL of 10M concentrated NaOH solution, ultrasonically dispersed for 30min, transferred to the reactor, and reacted in an oven at 160°C for 8h. The product was washed with deionized water, then soaked in 0.1M hydrochloric acid solution for 12h, then washed with deionized water to neutrality, then dried in an oven at 80℃ for 15h, and calcined in a muffle furnace at 400℃ for 6h to obtain TiO 2 Nanotubes, get TiO 2 nanotube.

[0054] Weigh the prepared TiO 2 0.2591g of nanotubes, dissolved in 10mL ethanol, add 0.0568g (0.2351mmol) of copper nitrate to it, stir evenly, then add 800μL of 1M sodium hydroxide solution and stir for 24h; stir and add 550μL of solution concentration (mass fraction) to 80 % Hydrazine hydrate (9.0702mmol), reacted at 80℃ for 2h to obtain Cu core supported on TiO 2 Nanotube surface; then add 10mL ethanol, 0.0686g (0.2359mmol) nickel nitrate, 800μL of 1M sodium hydroxide solution and 550μL of 80% hydrazine hydrate to t...

Embodiment 15

[0058] 1gTiO 2 The powder was dissolved in 25mL of 10M concentrated NaOH solution, ultrasonically dispersed for 30min, transferred to the reactor, and reacted in an oven at 160°C for 8h. The product was washed with deionized water, then immersed in 0.1M hydrochloric acid solution for 12h, then washed with deionized water to neutrality, then dried in an oven at 80℃ for 15h, and calcined in a muffle furnace at 400℃ for 6h to obtain TiO 2 Nanotubes, get TiO 2 nanotube.

[0059] Weigh the prepared TiO 2 0.2591g of nanotubes, dissolved in 10mL of ethylene glycol, add 0.0477g (0.1640mmol) of nickel nitrate to it, stir evenly, then add 800μL of 1M sodium hydroxide solution and stir for 24h; add 550μL of solution concentration (mass fraction) 80% hydrazine hydrate (9.0702mmol), reacted at 60℃ for 1h to obtain Ni core supported on TiO 2 Nanotube surface. The solution was centrifuged, the supernatant was removed, the precipitate was uniformly dispersed in 10 mL of ethanol, 0.0866 g (0.3584...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com