Rechargeable aluminum-sulfur battery and preparation method thereof

An aluminum-sulfur battery and aluminum foil technology, applied in the field of electrochemistry, can solve the problems of increasing aluminum anode polarization, low utilization rate of active materials, and reducing utilization rate of electrodes, so as to improve capacity characteristics, solve dissolution loss, and reduce capacity loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of cathode sulfur / conductive activated carbon composite material: mix high-purity sulfur and conductive activated carbon according to the mass ratio of 1:7 (1:3 / 3:5 / 1:1 / 5:3 / 3:1 / 7:1) Finally, grind in a ceramic mortar for 30 minutes, and then put it into a ball mill for 12 hours to obtain a uniformly mixed black powder. Put the black mixed powder into the hydrothermal kettle, make the hydrothermal kettle airtight in an inert gas environment, and heat the hydrothermal kettle for 12 hours at 155-165°C. After the reaction is completed, take out the black powder and grind it for 30 minutes The sulfur / conductive activated carbon composite material can be obtained.

Embodiment 2

[0043] The positive electrode active material that embodiment 1 obtains and conductive agent and binding agent are configured positive electrode coating slurry in the ratio of 16:1:15 by weight, take high-purity sulfur / conductive activated carbon as positive electrode active material, add conductive agent and For the binder, a solvent is added in a ratio of 5 g to 10 ml of solvent, and mixed uniformly to prepare a positive electrode active material slurry. Coat the prepared positive electrode active material slurry on a 0.03mm thick nickel current collector, dry it at 60°C for 3 hours, cut it into a 50mm wide × 50mm long positive electrode sheet, and then combine it with a 50mm wide × 50mm long aluminum foil Spot-weld the positive and negative metal lugs with a width of 4 mm at the corresponding positions, then stack the positive plate with a 0.1 mm thick glass fiber fabric diaphragm and negative aluminum foil, dry at 60°C for 30 minutes, and then transfer to an inert gas envi...

Embodiment 3

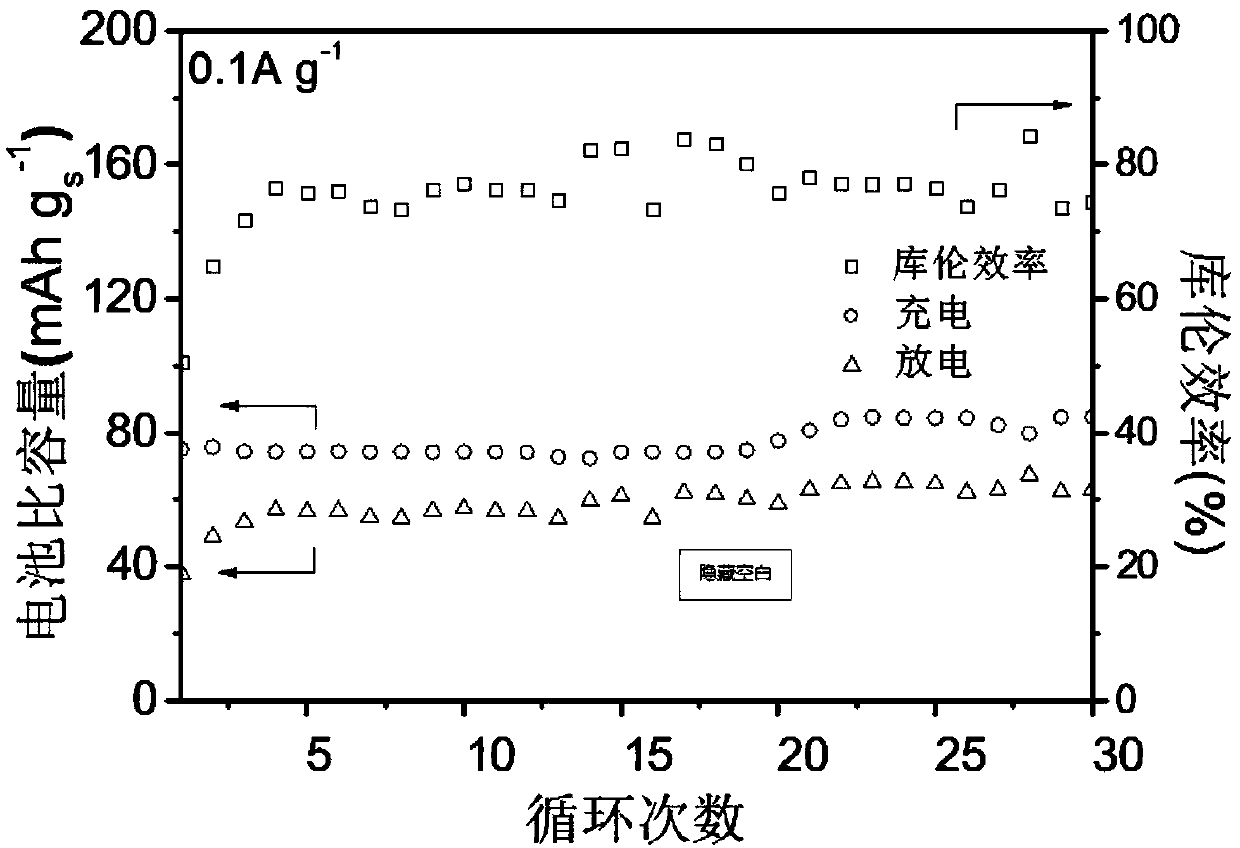

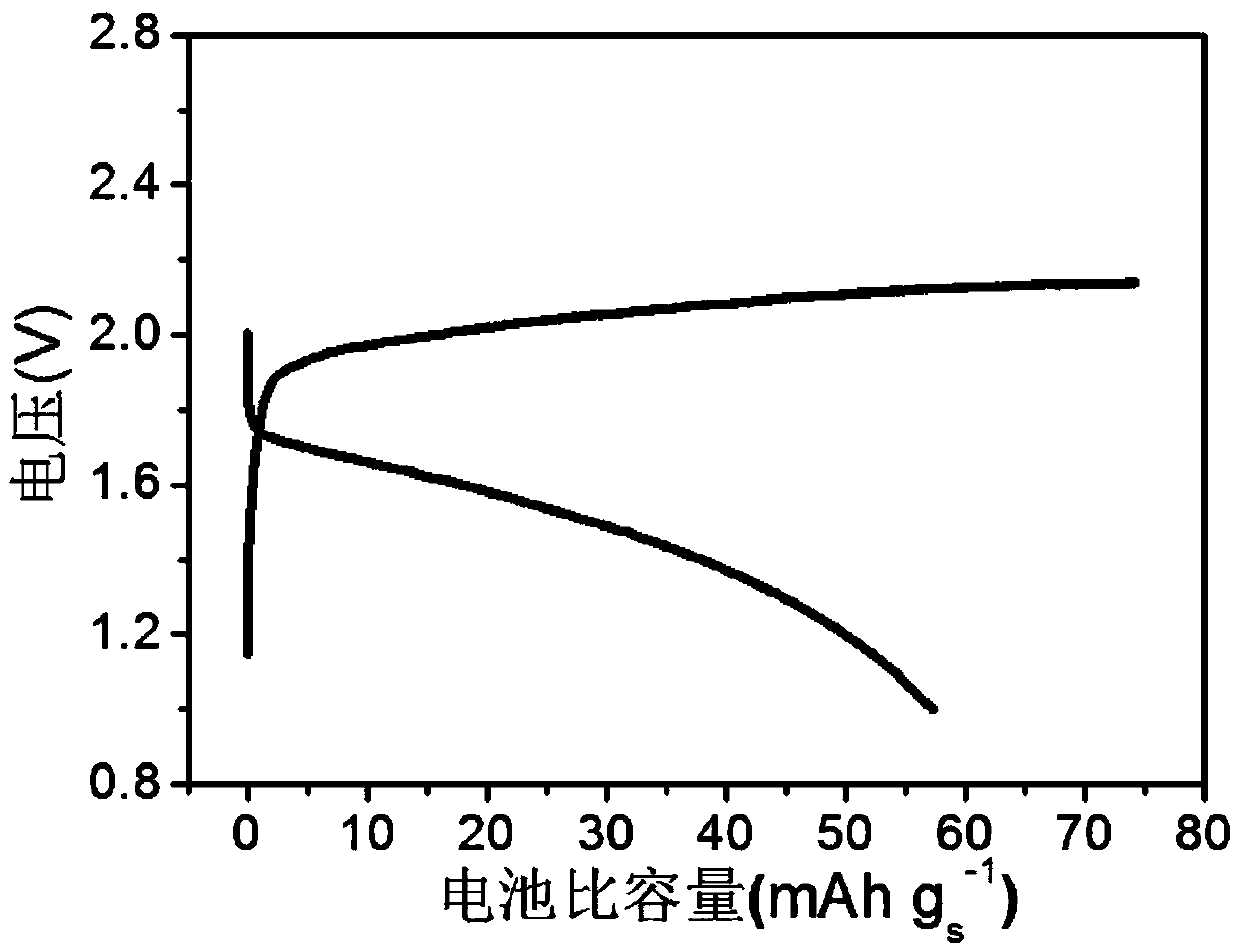

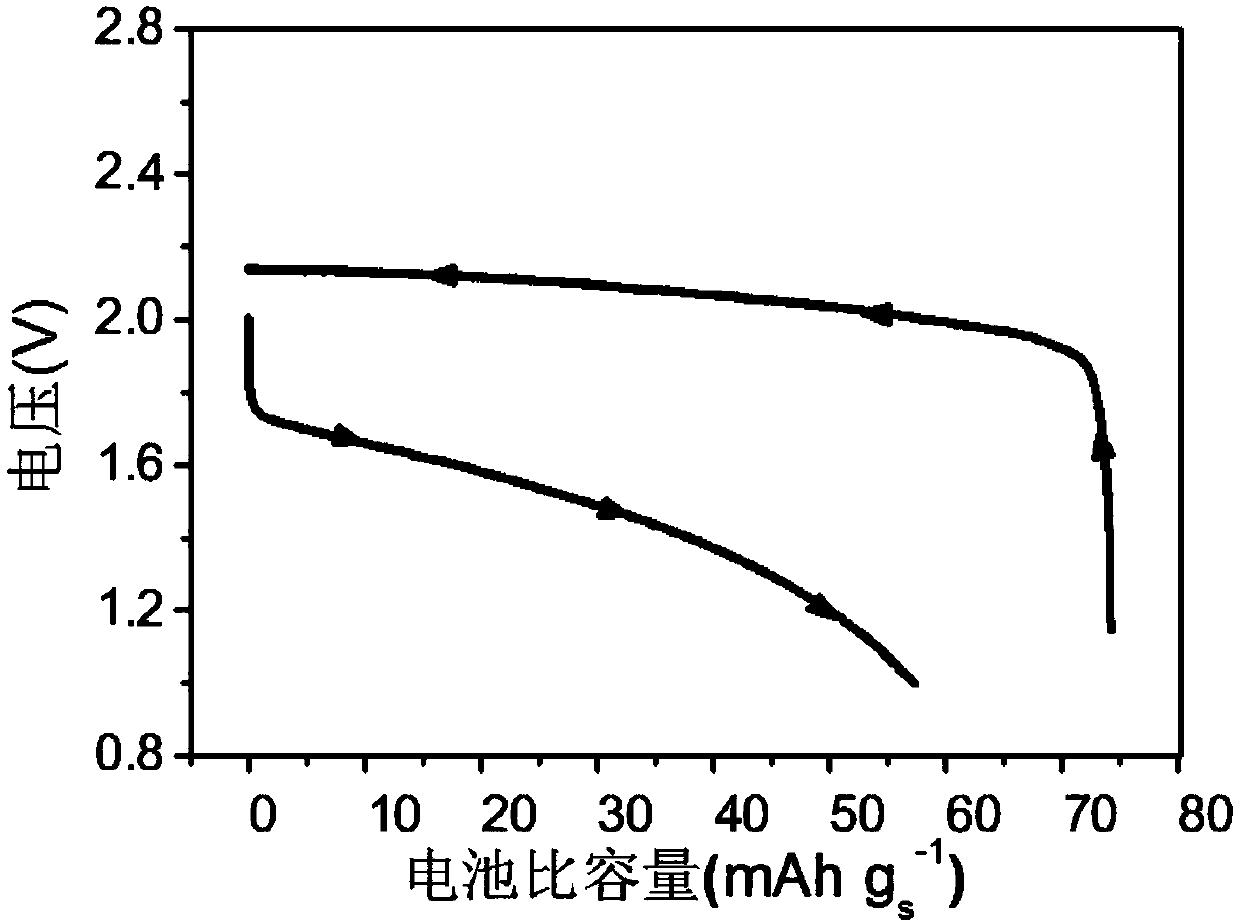

[0045] The positive electrode material was prepared according to the method described in Example 1, the carbon material substrate was replaced with superconducting carbon (Super-p), and the battery was assembled in the same method as in Example 2. During the battery charge-discharge cycle test, charge to 2.4V at 1A / g, discharge to 0.7V at 1A / g, the open circuit voltage of the battery is 1.08V, the highest discharge specific capacity is 223.7mAh / g, and the highest discharge specific energy is 356.6Wh / kg. After 60 charge-discharge cycles, the discharge specific capacity is 160.7mAh / g, the discharge specific energy is 256.1Wh / kg, and the charge-discharge Coulombic efficiency remains above 90%. The discharge platform is around 1.75V, and the charge and discharge platform voltage drop is around 0.56V. Figure 4 It is the cycle number-cycle efficiency-charge-discharge specific capacity curve of the aluminum-sulfur battery using sulfur and superconducting carbon (Super-p) composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com