'Main-auxiliary' activated sludge method for coupling deodorization and strengthening nitrogen and phosphorus removal

A technology for activated sludge, nitrogen and phosphorus removal, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc. Microbial activity and other problems, to achieve the effect of strengthening the biological phosphorus removal effect of the system, overcoming the instability of phosphorus removal effect, and increasing the content of nitrifying bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Take a certain 50,000 m 3 / d Sewage plant upgrading and upgrading as an example, the discharge standard of upgrading and upgrading is upgraded from Class A standard to "quasi-four category".

[0056] Removal rate table of pollutants in and out of a sewage treatment plant

[0057]

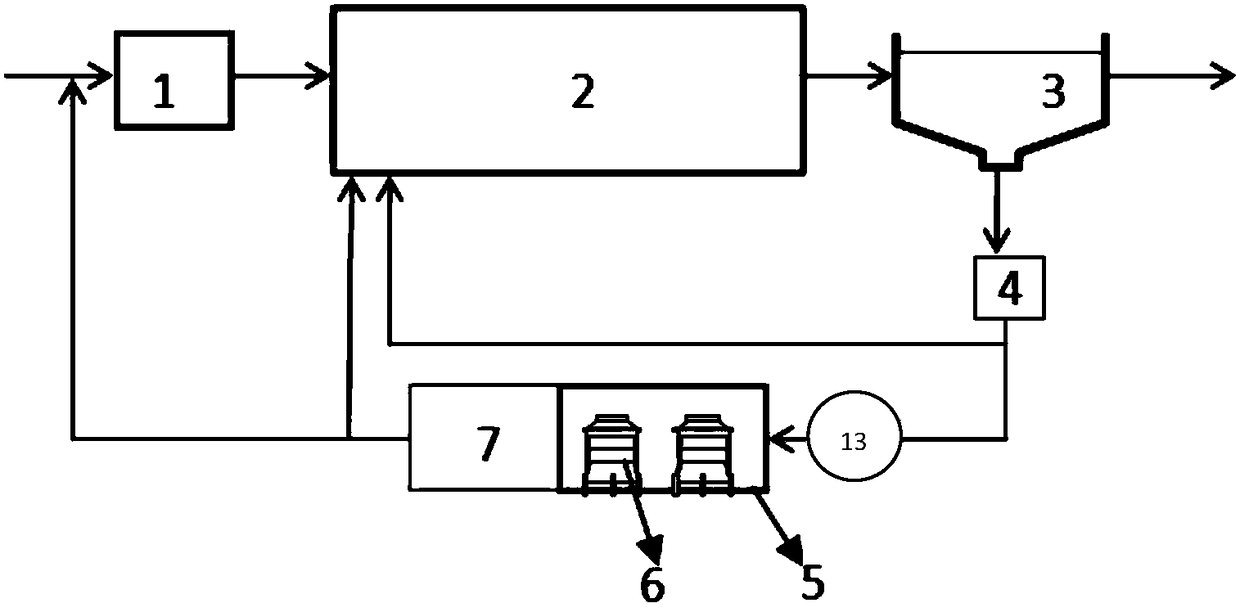

[0058] For this reason, the technological process of this transformation plan is as follows: figure 1 , select the "S2HBR-S2ASH process" involved in the present invention, build a new group of side flow "S2HBR-S2ASH", respectively adopt two rectangular reaction tanks and connect them in series, and return the pump room sludge to 105m 3 / h after being filtered by two micro-sieves with a filtration precision of 250 microns, it flows through the side flow S2 pool sequentially, and the remaining RAS is directly returned to the anaerobic pool. Among them, the S2HBR pool is equipped with 12 microbial culture tanks, and the upper and lower layers of biological culture beds in the tank are pre-f...

Embodiment 2

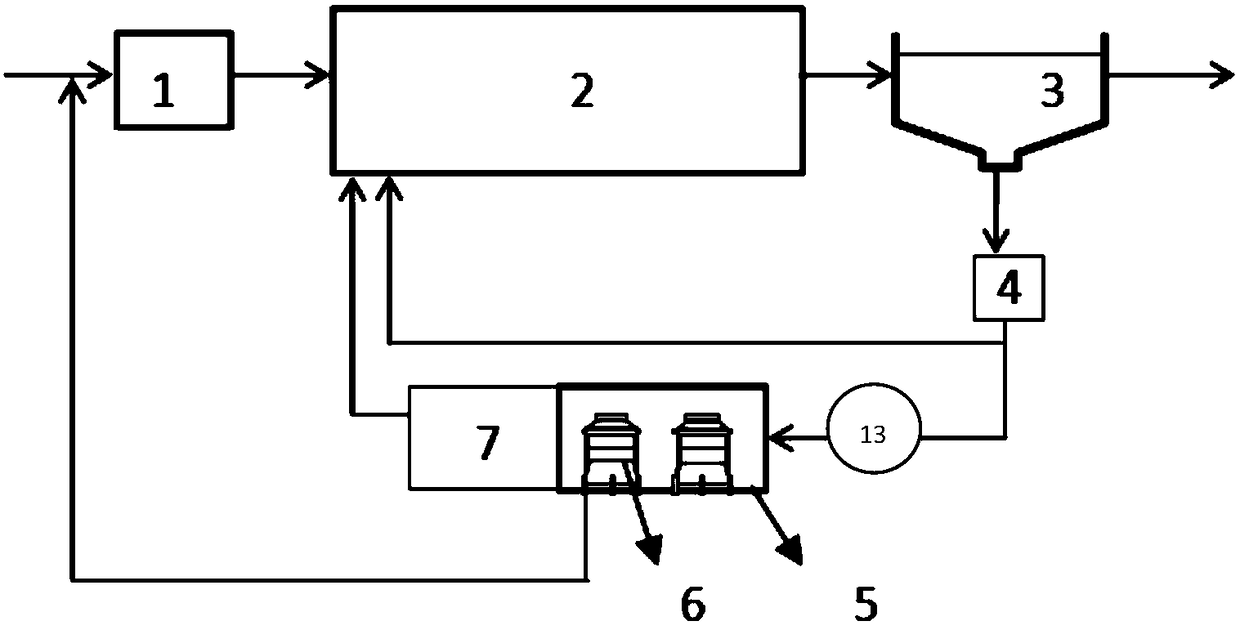

[0060] Due to the increase in the concentration of influent pollutants, the A sewage treatment plant in a certain city cannot meet the standards stably, and the air pollution to the surrounding environment is relatively large, causing complaints from nearby residents. Upgrading and upgrading and adding deodorization measures, the scale of the plant is 120,000 m 3 / d, using the Carrousel 2000 oxidation ditch process. The process flow of this transformation plan is as follows: figure 2 , transforming the original 4 grid series anaerobic pools into S2HBR pools (the first 3 grids) and S2ASH pools (the last 1 grid), in which 24 microbial culture tanks are placed in the S2HBR pools, and the tanks are filled with two layers of fillers, S and F, and Increase the aeration device, design the main biological MLSS to be 4000mg / L, control the frequency conversion of the total return flow at 33%-40%, control the actual return sludge concentration at 12000-14000mg / L, and return the total a...

Embodiment 3

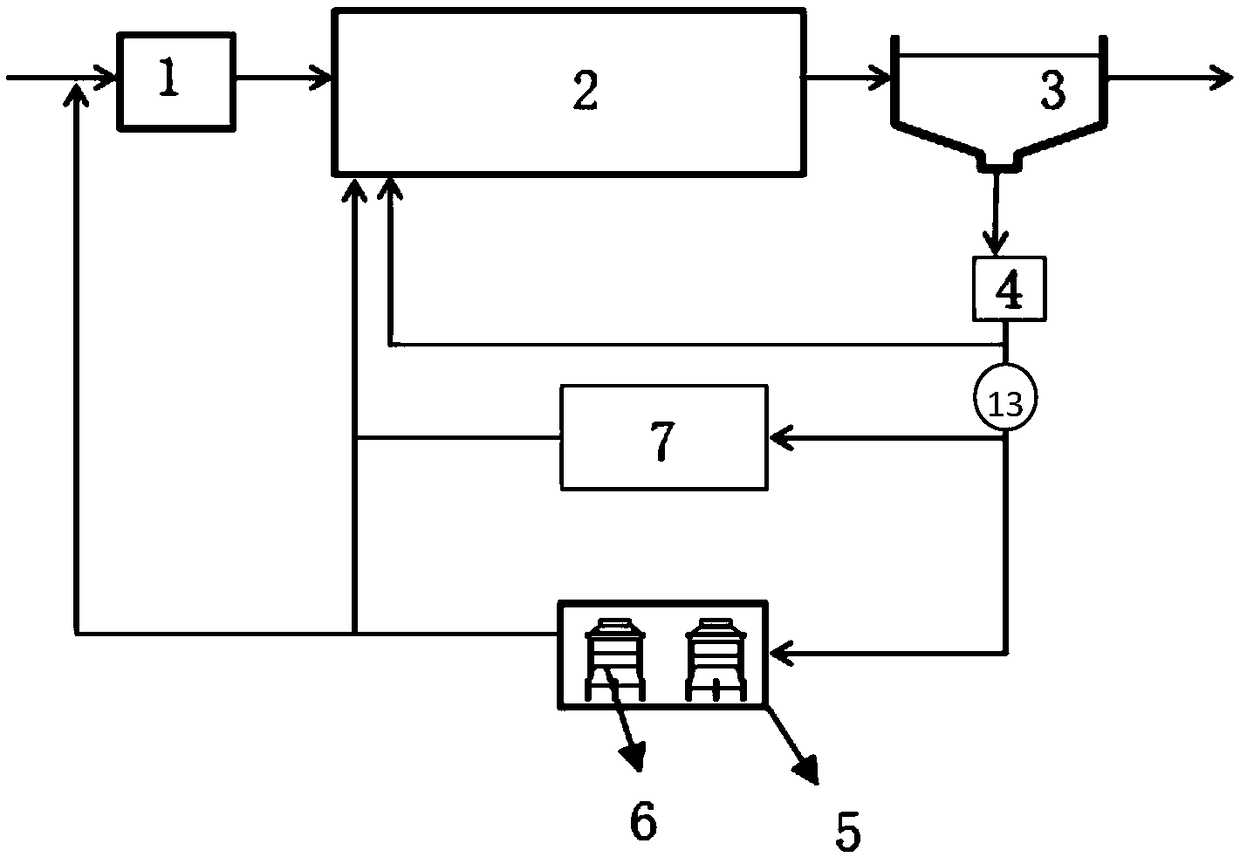

[0062] A certain 60,000 m 3 / d Sewage plant, raised from Grade B to "quasi-four" standard, requiring COD=40mg / L, TN=10mg / L, TP=0.3mg / L, NH3-N=2mg / L. The primary organism pool is the Aubert Oxidation Ditch. The process flow of this transformation plan is as follows: image 3 , the original selection tank was transformed into a side-flow S2ASH tank, and a new S2HBR tank was built, in which 18 microbial culture tanks were placed in the S2HBR tank (two layers of S and F fillers were filled in the tank), and the two side-flow tanks were operated in parallel mode. The MLSS of the main organism is 4.5g / L, the reflux ratio is controlled by frequency conversion speed regulation to 33%-45%, the concentration of the reflux sludge is controlled at 14500-18000mg / L, and the sludge is drawn from the sludge reflux pump room for 135m 3 / h, after being filtered by two 300 micron micro-sieves, it is sent to the S2 pool, and the return sludge is 60m 3 / h to the S2HBR pool, the residence time o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com