Three-dimensional orderly macroporous ferronickel phosphide material and preparation and application thereof

A three-dimensional ordered, phosphide technology, applied in the direction of phosphides, phosphorus compounds, chemical instruments and methods, etc., can solve the problem that catalyst materials cannot be fully and effectively used, the growth sites of nanosheets cannot be effectively controlled, and pores cannot be obtained Structure and other issues, to achieve the effect of good stability, high specific surface area, large pore volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

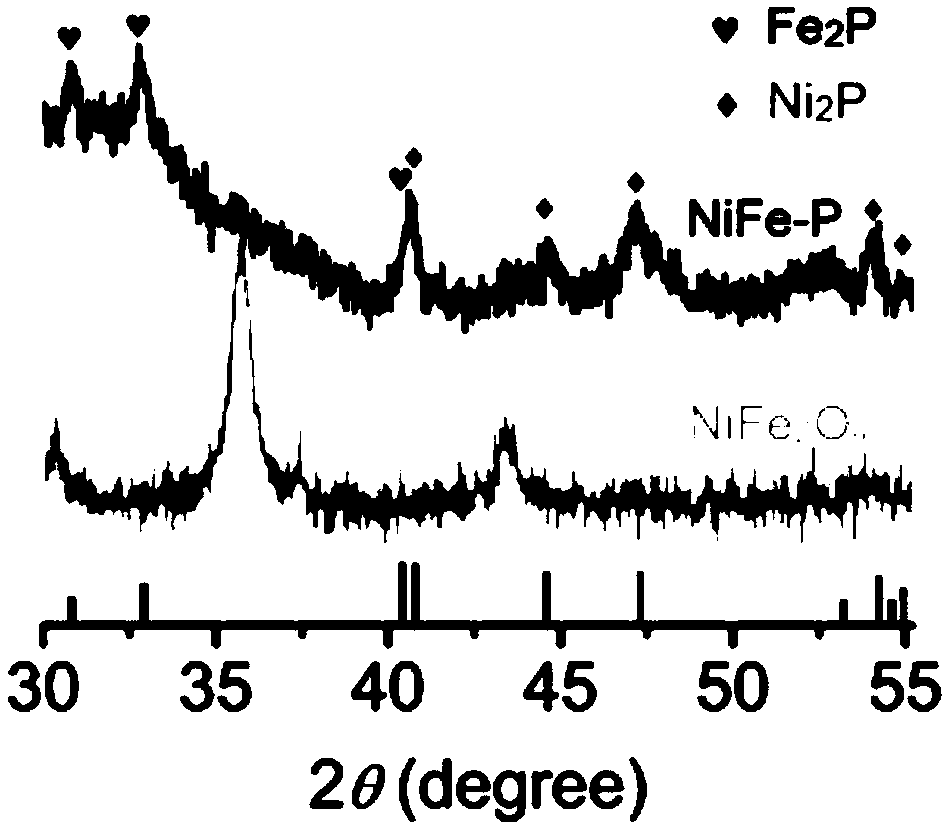

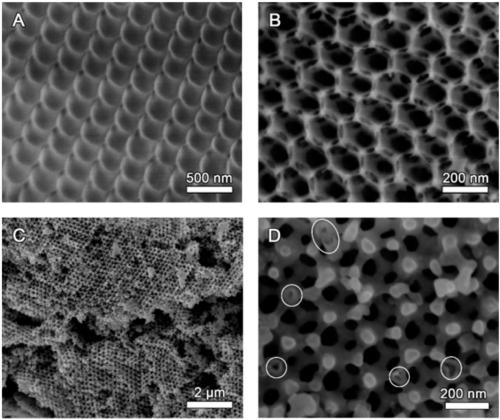

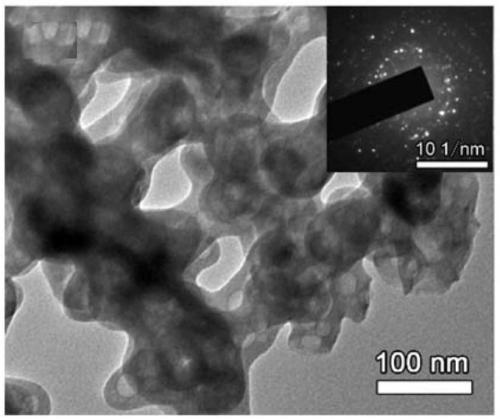

[0045] Synthesis of 3DOM NiFe-P

[0046] (1) Preparation of PMMA colloidal crystals

[0047] Add 300ml of deionized water to a 500ml round bottom flask, then put it into an oil bath, the temperature of the oil bath is 70°C, the rotation speed is 400 rpm, and nitrogen protection gas is introduced at the same time. After the temperature stabilized, add 80 mg of potassium persulfate solid, add 25 ml of methyl methacrylate (MMA) after the solid dissolves, and react for 1.5 hours under the protection of a nitrogen atmosphere to obtain a monodisperse polymethyl methacrylate with a spherical diameter of 300 nm. (PMMA) microspheres white emulsion. After the reaction, the product is centrifuged and washed to remove impurities. The PMMA microsphere emulsion obtained by washing is divided into 10ml glass beakers, and then the above beakers are placed in a water bath at 80° C. to evaporate and remove water to obtain orderly arranged PMMA solids.

[0048] (2) 3DOM NiFeO x preparation o...

Embodiment 2

[0058] Using the 3DOM NiFe-P material obtained in Example 1 as a hydrogen evolution catalyst to prepare a working electrode, the specific steps are as follows:

[0059] The electrochemical performance was tested in a three-electrode system electrolytic cell. The working electrode was a glassy carbon electrode loaded with 3DOM NiFe-P catalyst material, the counter electrode was a carbon rod, and the reference electrode was a saturated calomel electrode. Electrocatalytic performance in N 2 Tested in saturated 1M KOH solution. The sweep speed of LSV test is 2mV s –1 . The experimental test temperature is 25±2°C.

[0060] The preparation method of the working electrode: use an analytical balance to weigh 4 mg of electrocatalyst and use a pipette gun to draw 80 μl of 5wt% Nafion solution and disperse it into 1 ml of a mixed solution of deionized water and ethanol with a volume ratio of 4:1, and uniformly disperse in an ultrasonic instrument to form For the suspension, take 5 μl...

Embodiment 3

[0066] Synthesis method of 3DOM NiFe-P:

[0067] (1) Preparation of PMMA colloidal crystals

[0068] Add 300ml of deionized water to a 500ml round bottom flask, then put it into an oil bath, the temperature of the oil bath is 70°C, the rotation speed is 400 rpm, and nitrogen protection gas is introduced at the same time. After the temperature stabilized, add potassium persulfate solid, add methyl methacrylate (MMA) (the molar ratio of MMA and potassium persulfate is 1:0.001) after the solid dissolves, react under nitrogen atmosphere protection for 2 hours, obtain the A white emulsion of dispersed polymethylmethacrylate (PMMA) microspheres. After the reaction, the product is centrifuged and washed to remove impurities. The PMMA microsphere emulsion obtained by washing is divided into 10ml glass beakers, and then the above beakers are placed in a water bath at 80° C. to evaporate and remove water to obtain orderly arranged PMMA solids.

[0069] (2) 3DOM NiFeO x preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com