A kind of geopolymer-based antibacterial coating and its preparation method and application

An antibacterial coating and geopolymer technology, applied in anti-corrosion coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of restricting the development of new coatings, complex molecular design and synthesis process, etc., to achieve excellent antibacterial properties, Break through the effect of high brittleness and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

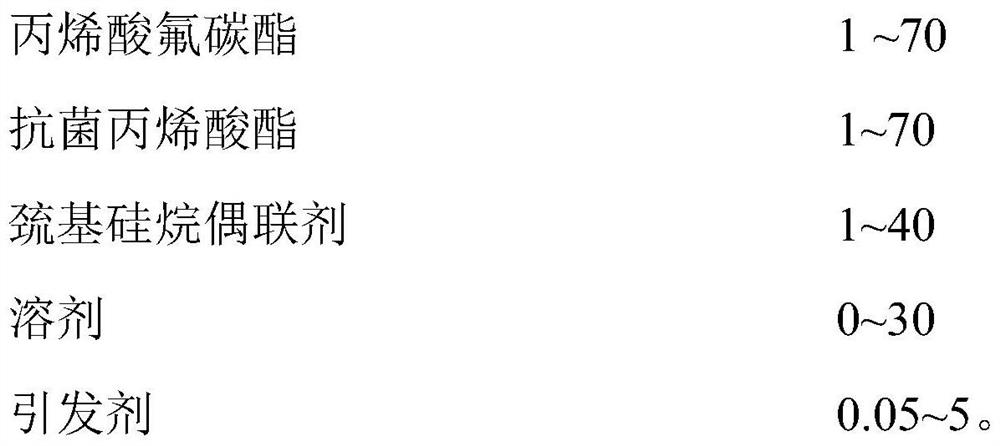

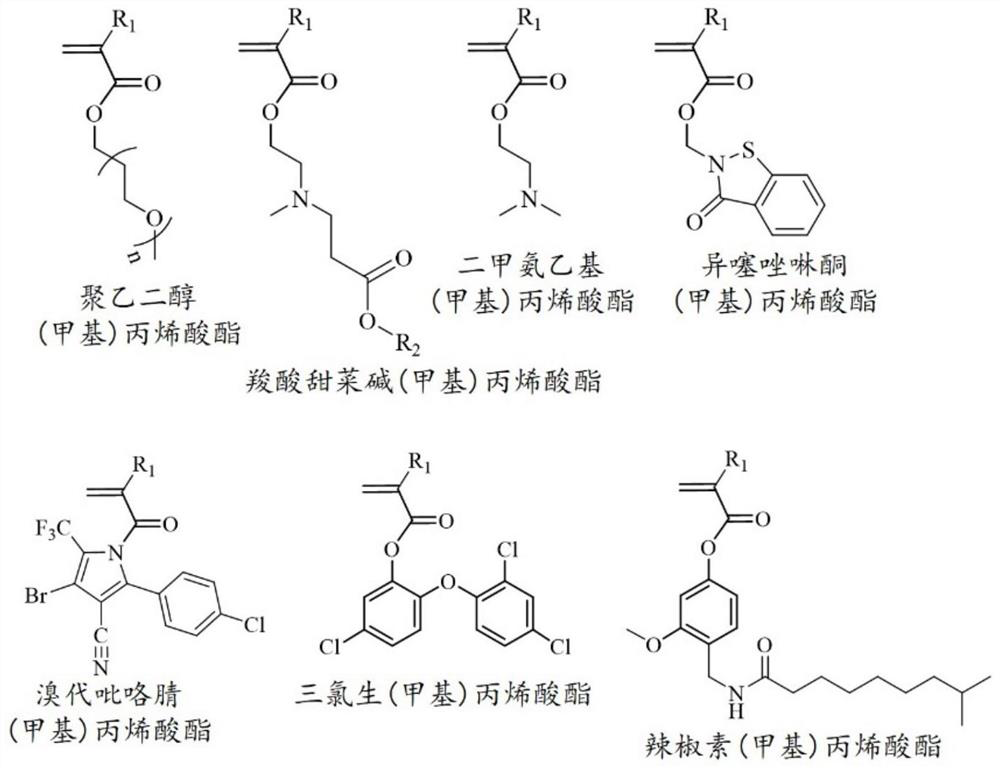

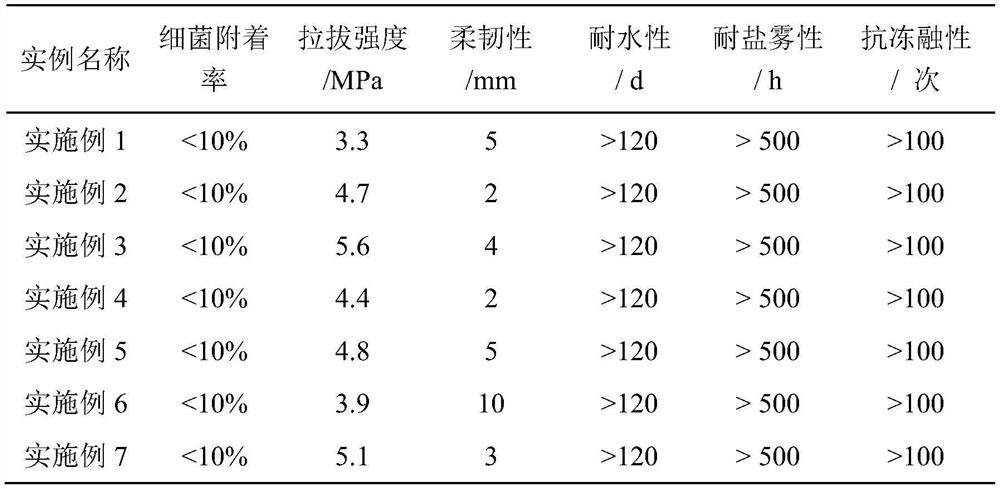

[0048] (1) In the reaction vessel, add 15 parts by weight of octafluoropentyl acrylate, 15 parts by weight of hexafluorobutyl methacrylate, 10 parts by weight of isothiazolinone acrylate, 10 parts by weight of capsaicin acrylate, 20 parts by weight Carboxylic acid betaine methacrylate, 19.9 parts by weight of mercaptomethyltrimethoxysilane, 10 parts by weight of toluene, 0.1 part of azobisisobutyronitrile, reacted for 48 hours under an inert gas atmosphere at 60 ° C, and removed the solvent to obtain antibacterial Telomers.

[0049] (2) Mix 56 parts by weight of metakaolin, 5 parts by weight of titanium dioxide, 10 parts by weight of zinc oxide, 18 parts by weight of glass flakes, and 11 parts by weight of heavy calcium carbonate to obtain component A. Mix 45 parts by weight of sodium water glass with a modulus of 0.8, 15 parts by weight of sodium hydroxide, 0.5 parts by weight of bentonite, and 39.5 parts by weight of water to obtain component B. Mix 77 parts by weight of an...

Embodiment 2

[0052] (1) In the reaction vessel, add 20 parts by weight of tetrafluoropropyl acrylate, 20 parts by weight of octafluoropentyl methacrylate, 30 parts by weight of nonafluorohexyl methacrylate, 0.5 parts by weight of polyethylene glycol acrylate, 0.5 parts by weight of bromopyrrole nitrile acrylate, 8.3 parts by weight of mercaptomethyltrimethoxysilane, 10 parts by weight of ethyl acetate, 10 parts by weight of acetone, and 0.7 parts by weight of phosphazene, reacted for 48 hours at 50 ° C under an inert gas atmosphere, Removal of the solvent yields the antibacterial telomer.

[0053] (2) Mix 40 parts by weight of fly ash, 4 parts by weight of carbon black, 15 parts by weight of cuprous oxide, 15 parts by weight of micaceous iron oxide, and 11 parts by weight of heavy calcium carbonate to obtain component A. Mix 57 parts by weight of sodium water glass with a modulus of 1.2, 7 parts by weight of potassium hydroxide, 3.1 parts by weight of bentonite, and 32.9 parts by weight of...

Embodiment 3

[0056] (1) In the reaction vessel, add 20 parts by weight of nonafluorohexyl acrylate, 20 parts by weight of carboxybetaine acrylate, 20 parts by weight of isothiazolinone methacrylate, 19.95 parts by weight of mercaptomethyltriethoxy Silane, 20 parts by weight of xylene, and 0.05 parts by weight of azobisisovaleronitrile were reacted at 80°C for 24 hours under an inert gas atmosphere, and the solvent was removed to obtain an antibacterial telomer.

[0057] (2) Mix 63 parts by weight of diatomite, 10 parts by weight of cement, 9 parts by weight of titanium dioxide, 7 parts by weight of zinc oxide, and 11 parts by weight of glass flakes to obtain component A. Mix 40 parts by weight of potassium silicate with a modulus of 1.7, 12.5 parts by weight of sodium hydroxide, 2.5 parts by weight of bentonite and 45 parts by weight of water to obtain component B. Mix 90 parts by weight of antibacterial telomer, 5 parts by weight of dimethyldiethoxysilane, and 5 parts by weight of hexadec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com