Method for large-area transfer of two-dimensional transition metal chalcogenide film and application thereof

A technology of chalcogenides and transition metals, which is applied in the field of large-area transfer of two-dimensional transition metal chalcogenides thin films, can solve the problems of easy damage and interface residues, and achieve the effects of reducing residues, reducing interface states, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Prepare a large-area molybdenum disulfide film on glass by physical vapor growth. The growth conditions are: use molybdenum disulfide powder as the source, place glass as the growth substrate in a tube furnace, and vacuum the tube furnace Finally, 30 sccm of argon gas is introduced as the carrier gas, and the temperature of the furnace body is heated to 900°C, so that the molybdenum disulfide powder evaporates and deposits crystals on the glass. After 30 minutes, a large area of molybdenum disulfide can be formed on the glass surface. film;

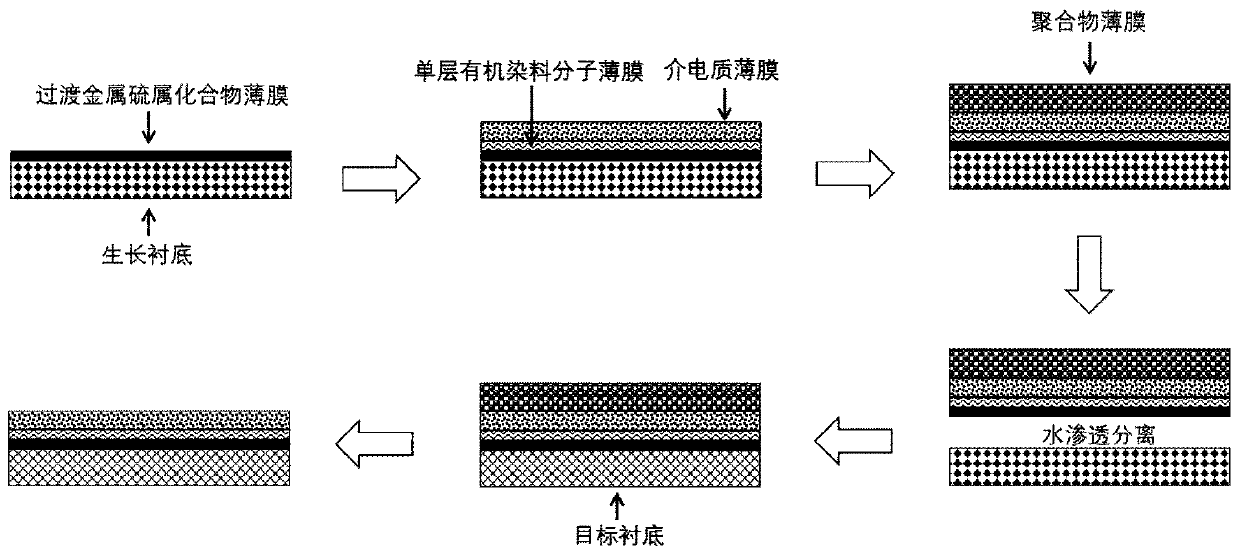

[0049] (2) Using van der Waals epitaxy technology and atomic layer deposition technology to integrate a single layer of 3,4,9,10-perylene tetracarbonyl diimide organic dye molecular film-alumina film on the surface of molybdenum disulfide film, and then Its surface is drop-coated with a layer of polyvinyl alcohol film, and the stacked structure obtained is as follows: figure 2 .

[0050] The growth conditions of monolayer ...

Embodiment 2

[0057] (1) Prepare a large-area molybdenum diselenide film on sapphire by chemical vapor deposition. The growth conditions are: molybdenum oxide powder and selenium powder are used as precursor reactants, and sapphire is used as the growth substrate. , the tube furnace is evacuated thickly, 20sccm argon is introduced as the carrier gas, and the temperature of the furnace body is increased to 800°C, so that the precursor reactants are evaporated and reacted. After one hour of growth, a large area of secondary Molybdenum selenide film;

[0058] (2) Using van der Waals epitaxy technology and atomic layer deposition technology to integrate a single layer of 3,4,9,10-perylenetetraacid dianhydride organic molecular film-alumina film on the surface of molybdenum diselenide film, and then on its surface Spin-coat a layer of polymethyl methacrylate film to obtain polymethyl methacrylate film / alumina film-single-layer 3,4,9,10-perylenetetraacid dianhydride molecular film / molybdenum di...

Embodiment 3

[0066] (1) Prepare a large-area molybdenum disulfide film on silicon oxide by chemical vapor deposition. The growth conditions are: use molybdenum oxide powder and sulfur powder as reaction precursors, use silicon oxide as the growth substrate, and place them in a tube furnace at intervals In the process, the tube furnace is evacuated thickly, 100sccm argon is introduced as the carrier gas, and the temperature of the furnace body is heated to 700°C, so that the molybdenum disulfide powder evaporates and deposits crystals on the silicon oxide. After 10 minutes, it can be in A large area of molybdenum disulfide film is formed on the surface of silicon oxide.

[0067] (2) Using van der Waals epitaxy technology and atomic layer deposition technology to integrate a single 3,4,9,10-perylene tetracarbonyl diimide organic molecular film-hafnium oxide film on the surface of the molybdenum disulfide film, and then on the surface A layer of polystyrene film is scraped and coated to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com