Fluorocarbon coating for aluminum curtain wall plate and spraying process of fluorocarbon coating

A fluorocarbon coating and aluminum curtain wall technology, applied in radiation-absorbing coatings, coatings, devices for coating liquids on surfaces, etc., can solve problems such as weak UV resistance, reduce the use of solvents, and speed up film formation , the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of modified fluorocarbon resin is as follows:

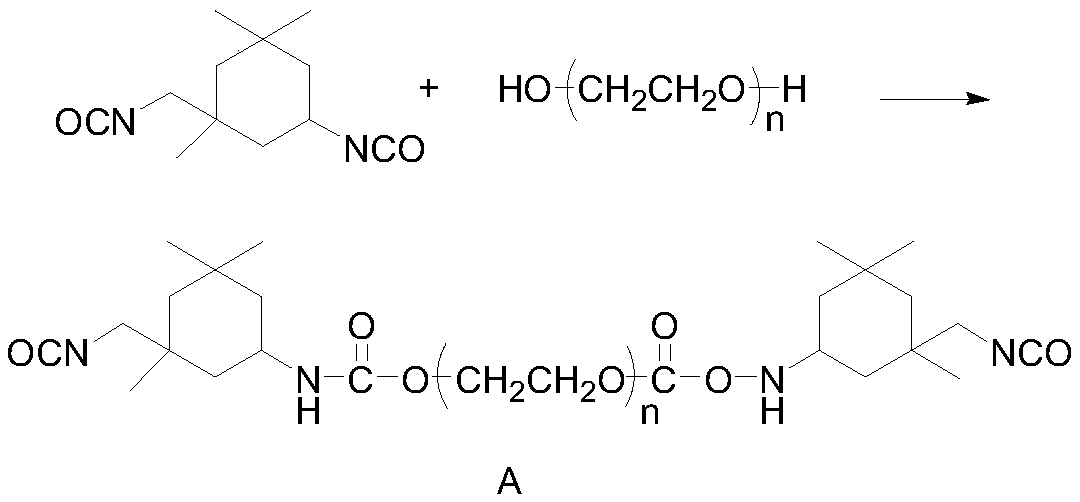

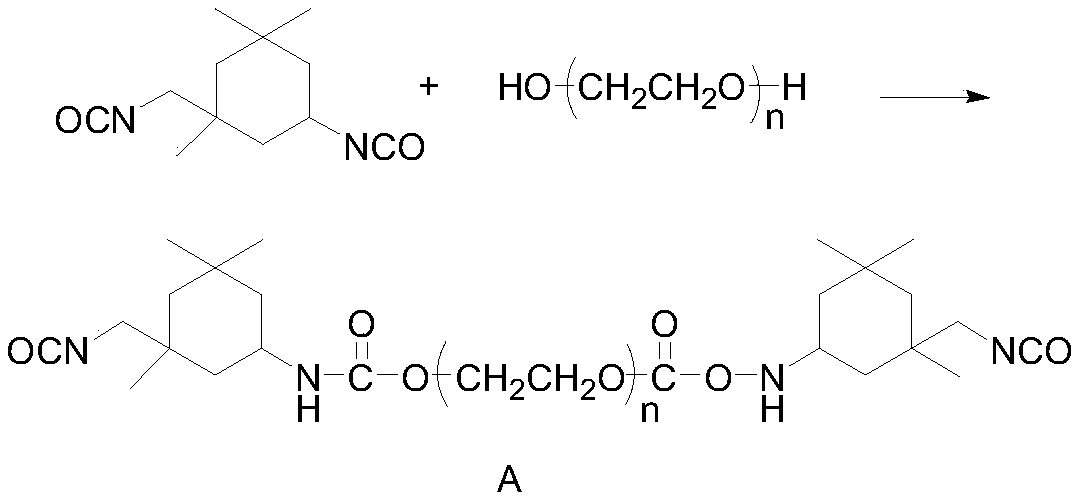

[0034] S1. Under the protection of nitrogen, add 1.5kg of isophorone diisocyanate into the reaction kettle, heat to 70°C under stirring, add 1kg of polyethylene glycol-200 dropwise and react for 4 hours to obtain compound A. The reaction formula is as follows:

[0035]

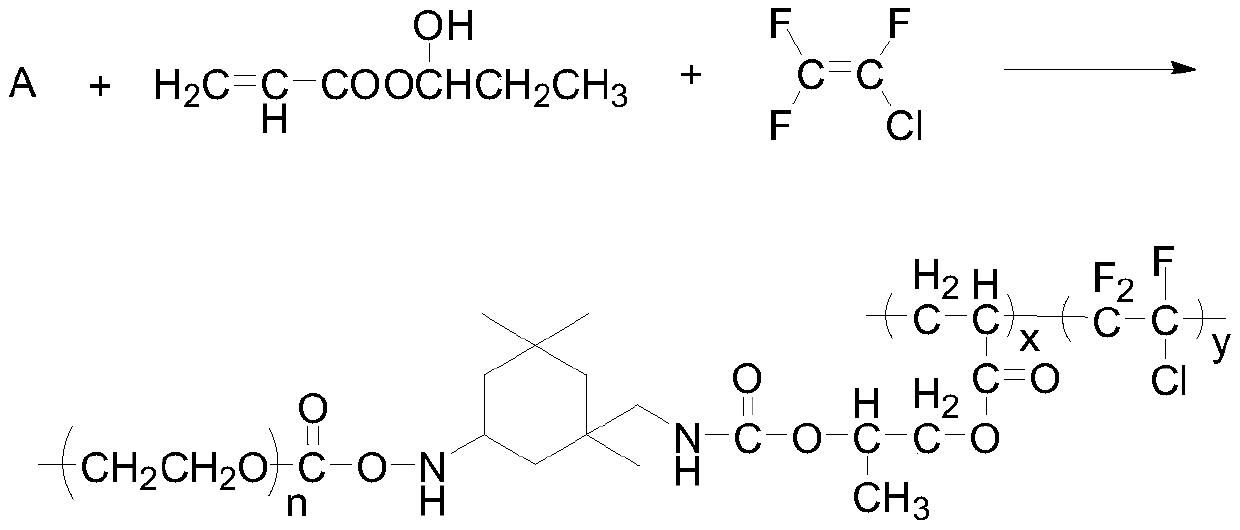

[0036]S2. Dissolve 150g of azobisisobutyronitrile in 300g of methyl isobutyl ketone, and add compound A obtained in S1. At the same time, add 800g of chlorotrifluoroethylene and 300g of hydroxypropyl acrylate, and heat up to 90°C to continue the reaction for 5-8h , Methyl isobutyl ketone is removed by distillation under reduced pressure to obtain a modified fluorocarbon resin, the reaction formula is as follows:

[0037]

Embodiment 2

[0039] The preparation method of nanocomposite particles is:

[0040] ① Add 100g of zinc acetate dihydrate solution and 5g of polyacrylamide into 1L of deionized water, heat to 60°C and mix evenly, add 30% ammonia water dropwise, adjust the pH to 12-14, and polish the clean silicon substrate Immerse in the mixed solution, heat in a water bath to 80°C for 3 hours, take out the silicon wafer, dry it in an oven, rinse it repeatedly with hot deionized water, and get ZnO nanorods after drying;

[0041] ② Add 100g nano-TiO 2 Add 200g ZnO nanorods into 1L ethanol solution, stir for 2h, then add 60g epoxy silane coupling agent, continue stirring for 2h, distill under reduced pressure to remove ethanol, dry in a vacuum oven and grind to obtain nanocomposite particles.

Embodiment 3

[0043] The preparation method of fluorocarbon coating is as follows:

[0044] (1) Dissolve 100g of wetting and dispersing agent HY257, 25g of emulsified silicone oil, and 100g of polyacrylamide in deionized water, and stir at a stirring speed of 200r / min for 30min until the wetting and dispersing agent of HY257, emulsified silicone oil and polyacrylamide are dispersed evenly Finally, add 1kg titanium dioxide and 50g of the nanocomposite particles obtained in Example 2, increase the stirring speed to 450r / min and stir for 30min to obtain the pigment slurry;

[0045] (2) Add 2kg methyl methacrylate and 25g emulsified silicone oil to the modified fluorocarbon resin prepared in 3kg Example 1, stir at 450r / min to make the defoamer disperse evenly to obtain a fluorocarbon resin emulsion;

[0046] (3) Mix the modified fluorocarbon resin emulsion with the pigment slurry, stir at a speed of 200r / min for 45min, add 10g of 2-hydroxy-2-methyl-1-phenylacetone, and then continue to stir at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com