A kind of slow-release microcapsule type polymer acid soil conditioner and preparation method thereof

A slow-release microcapsule and acidic soil technology, applied in the field of agricultural soil improvement, can solve the problems of deterioration of physical, chemical and biological properties, accumulation of heavy metals in soil, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

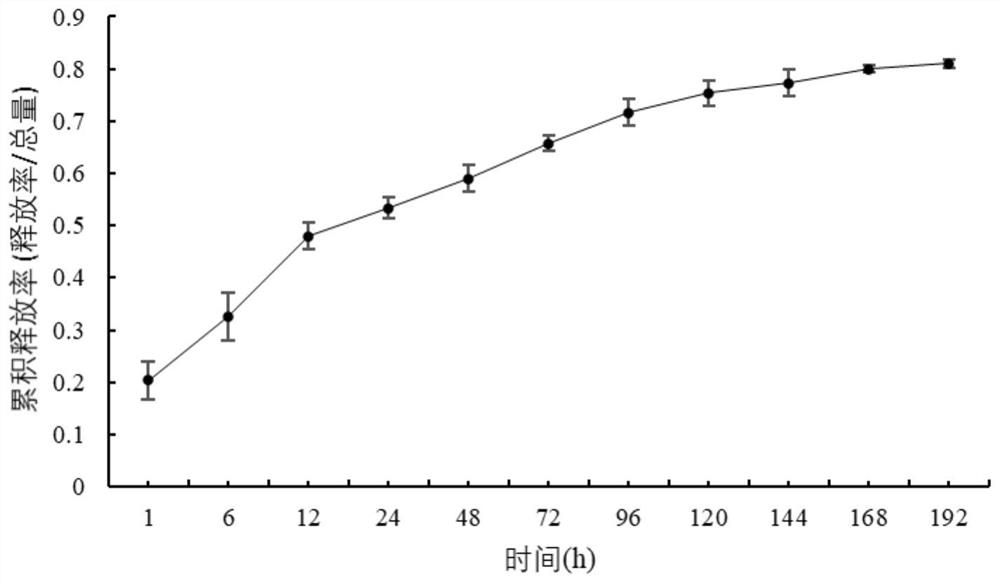

Image

Examples

Embodiment 1

[0060] 15 parts of chitosan oligosaccharides, 1 part of salicylic acid, 2 parts of potassium phosphate, 0.5 parts of dicyandiamide (DCD), and 5 parts of Tween 60 were dissolved in 100 parts of deionized water to obtain an aqueous phase;

[0061] 6 parts of Span 60 were dissolved in 200 parts of n-hexane to obtain oil phase I;

[0062] 5 parts of IPDI were dissolved in 50 parts of n-hexane to obtain oil phase II;

[0063] After the water phase is added to the oil phase I, carry out high-speed shear emulsification for 3 minutes at a speed of 3000 rpm; after the pre-emulsion is obtained, switch to overhead stirring, and add the oil phase II evenly at a speed of 1000 rpm. After 5 minutes, switch to 500 rpm for low-speed stirring The reaction was carried out for 8 hours, and the stirring speed was continued while maintaining the temperature of 50°C. The solution is recovered by rotary evaporation, and finally, the concentrated solution is filtered through a 0.22 micron ultrafiltra...

Embodiment 2

[0068] 15 parts of chitosan oligosaccharides, 1 part of naphthalene acetic acid, 2 parts of potassium sulfate, 0.5 parts of naphthalene acetic acid, 0.3 parts of 3,4-dimethylpyrazole phosphate (DMPP), 2.5 parts of Span 60 and 2.5 parts of Span 80 dissolved in 100 parts of deionized water to obtain an aqueous phase;

[0069] Prepare 40 parts of cyclohexane to obtain oil phase I;

[0070] Dissolving 0.01 part of MDI in 200 parts of cyclohexane to obtain oil phase II;

[0071] After the water phase is added to the oil phase I, carry out high-speed shear emulsification for 15 minutes at a speed of 3000 rpm, switch to overhead stirring after obtaining the pre-emulsion, and add the oil phase II evenly at a speed of 1000 rpm, and finish adding in 5 minutes, switch to 500 rpm for low-speed stirring The reaction was carried out for 8 hours, and the stirring speed was continued while maintaining the temperature of 50°C. Finally, the solution is recovered by rotary evaporation, and fin...

Embodiment 3

[0074] Dissolve 15 parts of chitosan oligosaccharides, 1 part of indole acetic acid, 3 parts of potassium silicate, 0.5 parts of indole acetic acid, 0.3 parts of potassium azide, 2.5 parts of Span 60 and 2.5 parts of Span 80 in 100 parts of deionized water , to obtain the aqueous phase;

[0075] Prepare 40 parts of biodiesel to obtain oil phase I;

[0076] Dissolve 0.01 part of MDI in 200 parts of biodiesel to obtain oil phase II;

[0077] After adding the water phase to the oil phase I, carry out high-speed shear emulsification for 15 minutes at a speed of 2000rpm, switch to overhead stirring after obtaining the pre-emulsion, and add the oil phase II dropwise at a speed of 1000rpm, after 5 minutes, switch to a low speed of 500rpm The reaction was stirred for 8 hours, and the stirring speed was continued while maintaining the temperature of 50°C. The solution is recovered by rotary evaporation, and finally, the concentrated solution is filtered through a 0.22 micron ultrafil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com