Ammonium dichromate and sodium sulfate mixed crystal as well as preparation method and application thereof

A technology for mixing crystals, sodium dichromate, applied in chemical instruments and methods, chromate/dichromate, chromium oxide/hydrate, etc., can solve feeding difficulties, combustion, explosion, unrealized components Proportion and particle size, etc., to achieve the effect of ensuring the yield and particle size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

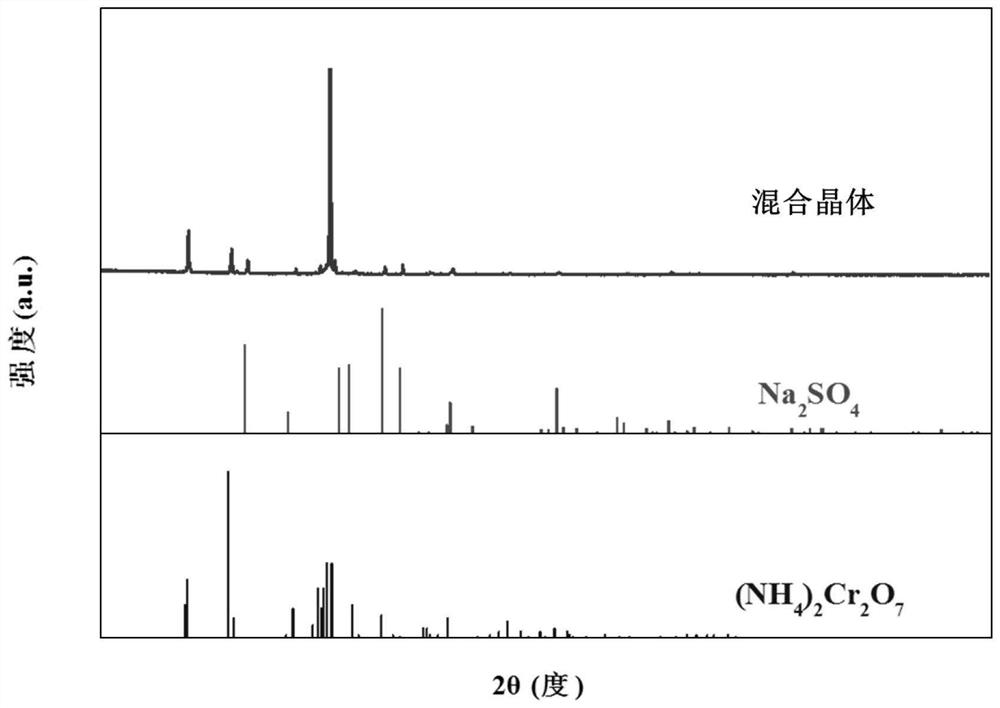

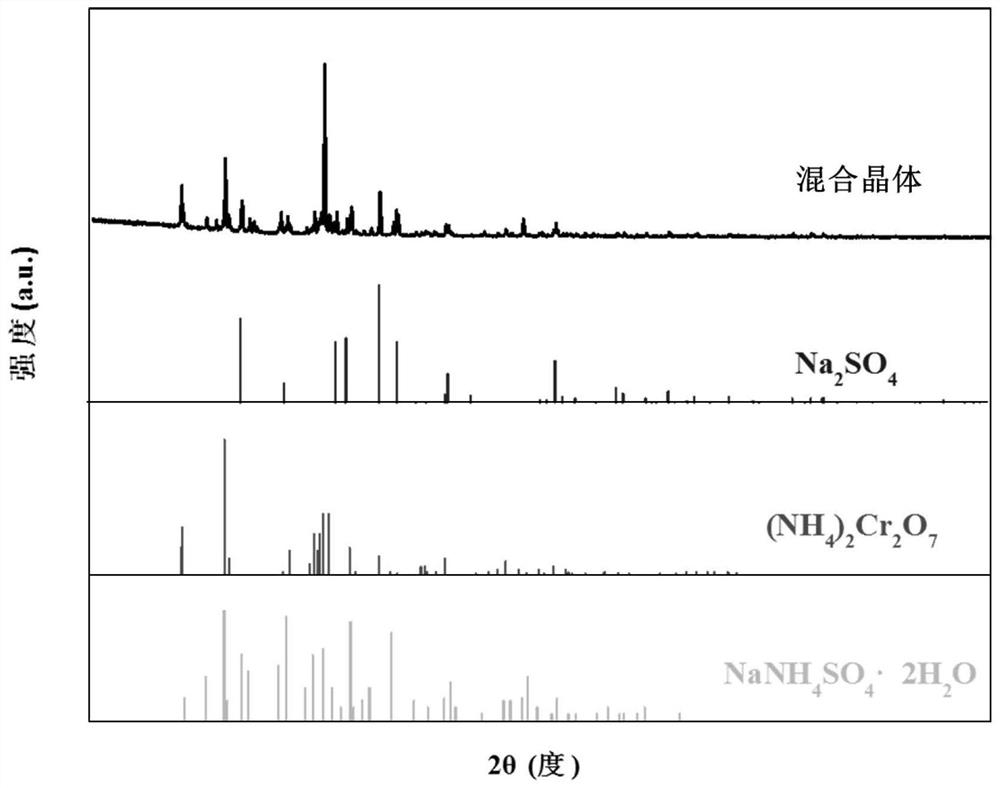

[0063] The specific embodiment part of the present invention provides a kind of ammonium dichromate and sodium sulfate mixed crystal and its preparation method and application, and described preparation method comprises:

[0064] (1) Cool and crystallize after the mixed solution of sodium dichromate and ammonium sulfate is heated up, obtain saturated saline solution;

[0065] (2) Add ammonium sulfate first after the saturated salt solution obtained in step (1) is heated up, then add sodium dichromate, wherein the mol ratio of sodium dichromate and ammonium sulfate is 1:(0.9~1.1), after stirring reaction Cool and crystallize to obtain mixed crystals and crystallization mother liquor, and the crystallization mother liquor returns to step (1).

[0066] Described mixed crystal is used for preparing chromium oxide green pigment, and preparation method comprises:

[0067] The mixed crystals of ammonium dichromate and sodium sulfate are calcined, washed and dried to obtain chromium ...

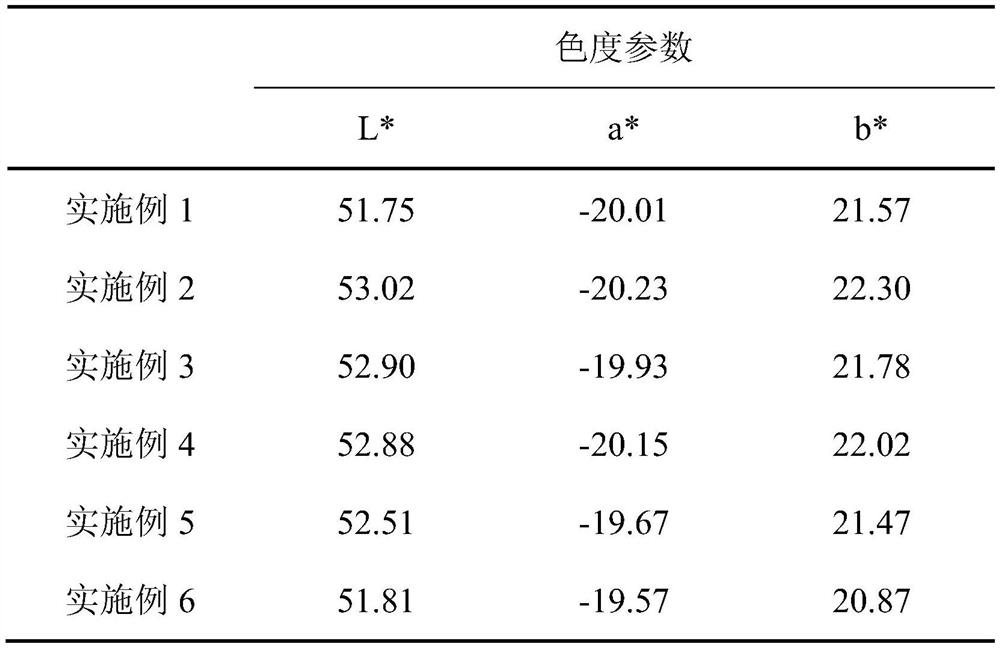

Embodiment 1

[0070] The present embodiment provides a kind of preparation method of ammonium dichromate and sodium sulfate mixed crystal and the purposes of preparing chromium oxide green pigment by mixed crystal, specifically comprise the following steps:

[0071] (1) heating sodium dichromate, ammonium sulfate and sodium sulfate saturated solution at room temperature to 40°C, cooling and crystallizing to room temperature, and separating solid and liquid to obtain a saturated salt solution;

[0072] (2) ammonium sulfate is dissolved in the saturated salt solution that step (1) obtains, and its mass fraction reaches 10wt%, obtains ammonium sulfate solution; Sodium dichromate is dissolved in the saturated salt solution that step (1) obtains, Make its mass fraction reach 30wt%, obtain sodium dichromate solution;

[0073] (3) at 40 DEG C, under stirring state, the sodium dichromate solution that step (2) obtains is joined in the ammonium sulfate solution that step (2) obtains, and wherein the...

Embodiment 2

[0079] The present embodiment provides a kind of preparation method of ammonium dichromate and sodium sulfate mixed crystal and the purposes of preparing chromium oxide green pigment by mixed crystal, specifically comprise the following steps:

[0080] (1) heating sodium dichromate, ammonium sulfate and sodium sulfate saturated solution at room temperature to 90°C, cooling and crystallizing to room temperature, and separating solid and liquid to obtain saturated salt solution;

[0081](2) ammonium sulfate is dissolved in the saturated salt solution that step (1) obtains, and its mass fraction reaches 12wt%, obtains ammonium sulfate solution; Sodium dichromate is dissolved in the saturated salt solution that step (1) obtains, Make its mass fraction reach 20wt%, obtain sodium dichromate solution;

[0082] (3) at 90 DEG C, under stirring state, the sodium dichromate solution that step (2) obtains is joined in the ammonium sulfate solution that step (2) obtains, and wherein the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com