High-performance colored glass fiber and preparation method thereof

A glass fiber and high-performance technology, which is applied in the field of high-performance colored glass fiber and its preparation, can solve problems such as poor wear resistance, complicated process steps, and labor and material resources, and achieve the goal of eliminating crystallization of leaky spouts, simple process steps, and increased strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

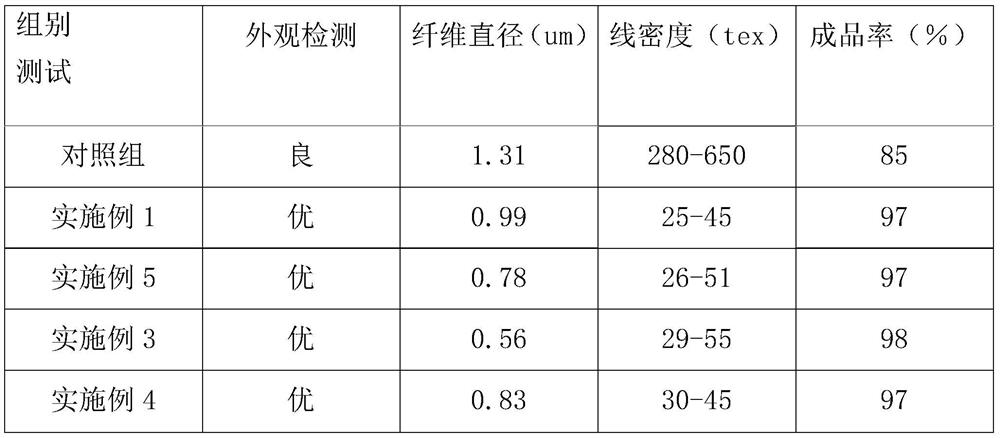

Examples

Embodiment 1

[0026] A high-performance colored glass fiber, its main components include: 50% silicon dioxide, 4% calcined alumina, 3% magnesium oxide, 2% calcium oxide, 7% sodium oxide, 0.1% potassium oxide, by weight percentage, Titanium oxide 0.01%, zirconia 0.01%, cobalt oxide 0.01%, cerium oxide 0.01%, titanium oxide 0.01%, and ferric oxide 0.1%.

[0027] Wherein, the calcined alumina is a high-purity alumina raw material prepared by the "Bayer process", and is calcined at a temperature of 950-1200° C. to obtain α-type alumina powder.

[0028] Among them, the moisture content of the calcined alumina is ≤1.0%, and the iron content is ≤0.15%.

[0029] A preparation method of high-performance colored glass fibers, comprising the following steps:

[0030] S1. Weigh various raw materials according to the formula weight, and then put the weighed raw materials into the screening machine for screening to remove impurities in the raw materials;

[0031] S2. Put the screened raw materials into...

Embodiment 2

[0041] A high-performance colored glass fiber, by weight percentage, silicon dioxide 60%, calcined alumina 10%, magnesium oxide 8%, calcium oxide 6%, sodium oxide 9%, potassium oxide 0.3%, titanium oxide 0.04%, Zirconia 1.2%, cobalt oxide 1.6%, cerium oxide 1.8%, titanium oxide 1.2%, and ferric oxide 0.25%.

[0042] A preparation method of high-performance colored glass fibers, comprising the following steps:

[0043] S1. Weigh various raw materials according to the formula weight, and then put the weighed raw materials into the screening machine for screening to remove impurities in the raw materials;

[0044] S2. Put the screened raw materials into a drying oven for drying treatment, and take them out after naturally cooling to normal temperature;

[0045] S3, then the dried raw materials in step S2 are pulverized and sieved to obtain pulverized materials, and then all kinds of pulverized materials are mixed uniformly to obtain a mixture;

[0046] S4, put the mixture obtai...

Embodiment 3

[0050] A high-performance colored glass fiber, by weight percentage, silicon dioxide 70%, calcined alumina 15%, magnesium oxide 10%, calcium oxide 10%, sodium oxide 13%, potassium oxide 1.6%, titanium oxide 0.05%, Zirconia 3%, cobalt oxide 5%, cerium oxide 4%, titanium oxide 1.63%, and ferric oxide 0.35%.

[0051] A preparation method of high-performance colored glass fibers, comprising the following steps:

[0052] S1. Weigh various raw materials according to the formula weight, and then put the weighed raw materials into the screening machine for screening to remove impurities in the raw materials;

[0053] S2. Put the screened raw materials into a drying oven for drying treatment, and take them out after naturally cooling to normal temperature;

[0054] S3, then the dried raw materials in step S2 are pulverized and sieved to obtain pulverized materials, and then all kinds of pulverized materials are mixed uniformly to obtain a mixture;

[0055]S4, put the mixture obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com