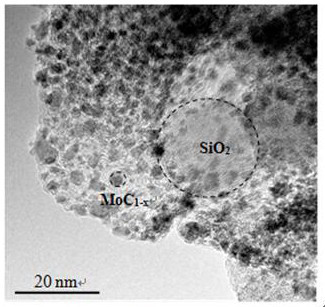

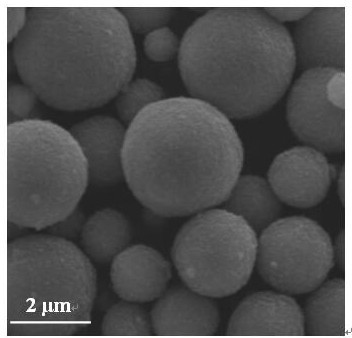

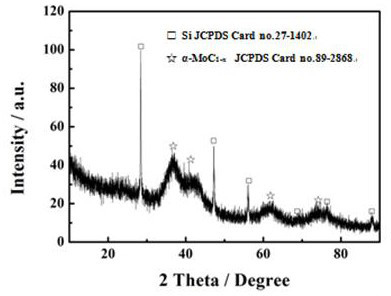

Alpha-MoC1-x/Si@C microsphere and preparation method and application thereof

A technology of microspheres and magnesium heating, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of increasing energy consumption, environmental damage, destroying the microstructure of products, etc., to improve the electronic conductivity and the reaction process. Mild, transfer-rate-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021](1) 5 ml of commercial silica suspension is diluted with deionized water to 25 mL, referred to as solution a, adjusted to 2 to 2 with dilute hydrochloric acid, and dissolve 0.475 g of dopamine and 1.2 g of sodium dihydrate The solution B, C is configured in 25 ml deionized water; (ie, the ratio of Mo element and C element is 1: 4, which can be sufficiently utilized to form a microsphere structure by the raw material; if this ratio is greater than 1: 2, although it can also obtain composite Microspheres, but its yield is small; if this ratio is less than 1: 4, it will cause increased carbon content in microspheres, and the silicon content is lowered, and the final product is lower than the specific capacity.) Place solution A in a magnetic stirrer The solution B and C were slowly added to the solution A, respectively, and the reaction was sufficiently carried out, and the orange red precipitate was produced, and stirred for 1 h;

[0022](2) The product in step (1) was washed with ...

Embodiment 2

[0032](1) 10 ml of commercial silica suspension is diluted with deionized water to 25 mL, referred to as solution a, adjusted pH to 2 with dilute hydrochloric acid, and dissolve 0.475 g of dopamine and 0.6 g of sodium dihydration sodium The solution B, C is disposed in 25 ml deionized water; (i.e., Mo element and C element ratio of less than 1: 4) are placed on a magnetic agitator to stir, and the solution B, C slowly adds the solution A, producing orange red. Precipitation, continuous stirring for 1 h;

[0033](2) The product in step (1) is washed with deionized water, ethanol, and the product is frozen 24h;

[0034](3) The drying product in (2) was raised to 1000 ° C at a temperature rise rate of 5 ° C / min in argon, and the carbonization treatment of 3 h was thermally treated;

[0035](4) A proportion of products in (3) with magnesium powder, aluminum chloride mass ratio 20: 13: 130, is loaded into the high pressure reactor, and the temperature is warmed to 300 ° C in the tube furnace. 1...

Embodiment 3

[0039](1) 5 ml of commercial silica suspension is diluted with deionized water to 25 mL, referred to as solution A, adjusted to 2 to 2 with dilute hydrochloric acid, and dissolved 0.238 g of dopamine and 1.2 g of sodium dihydration sodium A solution B, C is disposed in 25 ml of deionized water; (i.e., Mo element and C element ratio greater than 1: 2), the solution A is placed on a magnetic stirrer, and the solution B and C are slowly added to the solution A, respectively, produce orange red. Precipitation, continuous stirring for 1 h;

[0040](2) The product in step (1) is washed with deionized water, ethanol, and the product is frozen 24h;

[0041](3) The drying product in (2) was raised to 1000 ° C at a temperature rise rate of 5 ° C / min in argon, and the carbonization treatment of 3 h was thermally treated;

[0042](4) A proportion of products in (3) with magnesium powder, aluminum chloride mass ratio 20: 13: 130, is loaded into the high pressure reactor, and the temperature is warmed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com