Method for producing soil conditioner by using bulk industrial solid waste and product

A soil conditioner and industrial solid waste technology, which is applied in the field of agricultural resource utilization of bulk industrial solid waste, can solve the problems of low production cost, high calcination temperature, soil compaction, etc., and achieve low cost, wide sources, comprehensive nutrients and balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

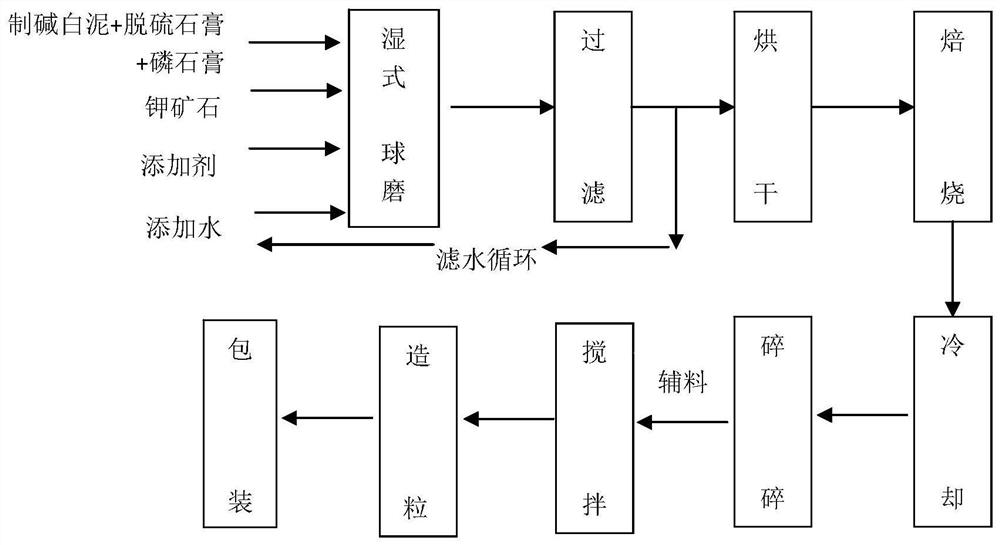

Method used

Image

Examples

Embodiment 1

[0050]A soda-making enterprise in Shandong produced a large amount of white mud (soda slag) produced by the ammonia-soda process, and there were also a large amount of flue gas desulfurization gypsum and phosphogypsum nearby. Potassium ore is mined from Yantai, Shandong, which contains 13.98% potassium oxide, 65.32% silicon dioxide, 18.01% aluminum oxide, and 2.69% sodium oxide, iron oxide, etc. The total content of various oxides is about 100%. Mix alkali-making white mud: desulfurization gypsum: phosphogypsum: potassium ore at a mass ratio of 28.89:8.59:10.95:51.57. These raw and auxiliary materials are required to contain heavy metal elements that meet the national standards for silicon calcium potassium magnesium fertilizers (GB / T36207- 2018), the ecological indicators of arsenic, cadmium, lead, chromium, and mercury, the contents (unit: mg / kg) are ≤50, ≤10, ≤200, ≤500, ≤5, and the particle size is ≥200 mesh (≤0.074mm). On this basis, add potassium chloride 2.5% + sodium s...

Embodiment 2

[0053] A large-scale soda production enterprise in Qinghai produced a large amount of white mud (alkali slag) produced by the ammonia-soda process, and the flue gas desulfurization facilities of the factory also produced a large amount of desulfurization gypsum, and a large amount of phosphogypsum was accumulated in the surrounding phosphate fertilizer enterprises. Potassium ore is collected from Golmud, Qinghai, which contains 9.56% potassium oxide, 68.46% silicon dioxide, 15.67% aluminum oxide, and 6.31% sodium oxide, iron oxide, etc. The total content of various oxides is about 100%. Mix the two materials of soda-making white mud: desulfurization gypsum: phosphogypsum: potassium ore at a mass ratio of 27.47:7.52:20.65:44.36. These raw and auxiliary materials are required to contain heavy metal elements that meet the national standards for silicon, calcium, potassium and magnesium fertilizers (GB / T36207-2018) ecological indicators of arsenic, cadmium, lead, chromium, mercury...

Embodiment 3

[0056] A large chemical enterprise in Hebei Province produced a large amount of white mud (alkali slag) produced by the ammonia-soda method. The factory adopted the limestone-gypsum method to implement wet flue gas desulfurization, and produced a large amount of desulfurized gypsum. There is also a compound fertilizer processing enterprise nearby. There is a large amount of phosphogypsum that is produced during the production of phosphoric acid. Potassium ore is mined from Tangshan, Hebei, which contains potassium oxide 9.28%, silicon dioxide 64.23%, aluminum oxide 13.58%, and other oxides such as sodium oxide, ferric oxide, titanium dioxide, manganese dioxide, and phosphorus pentoxide. The total content of the substance is about 12.91%. According to the mass ratio of soda-making white mud: desulfurization gypsum: phosphogypsum: potassium ore, the two materials are mixed according to the mass ratio of 25.89:34.59:12.95:26.57. These raw and auxiliary materials are required to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com