Magnetic biochar soil remediation agent for heavy metal pollution of soil, and preparation method and application thereof

A soil remediation agent and biochar technology, applied in the field of soil remediation, can solve the problems of unconsidered magnetization effect, single function, unknown effect of toxic metals, etc., achieving high practicability and application value, easy preparation and operation, and avoiding secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] One, prepare magnetic biochar soil remediation agent of the present invention

[0077] Follow the steps below:

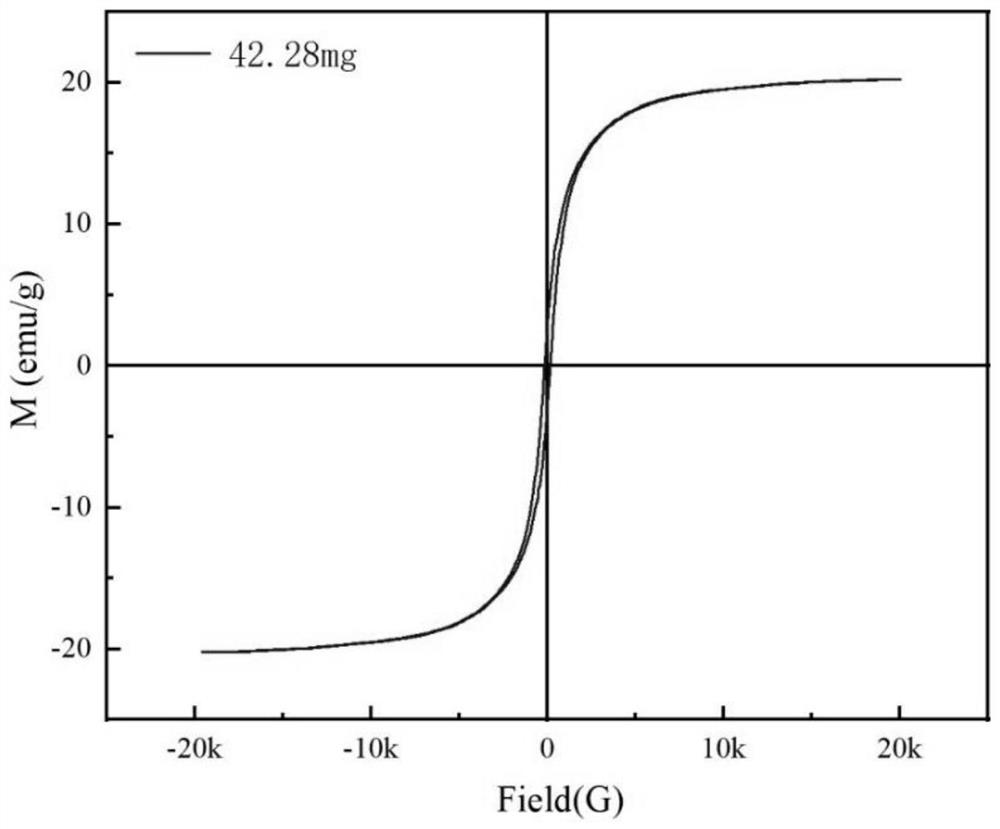

[0078] 1. Preparation of magnetic particles:

[0079] Take 100g of iron tailings from which impurities and silt have been removed, crush them with a crusher, wash with 200ml of 0.01M HCl solution, filter through a 60-mesh nylon sieve to obtain slag, place the slag in a high-temperature furnace for roasting, and pass through a strong magnet magnetic separation method after cooling down Collect magnetic particles. Among them, the roasting conditions: using a temperature-programmed muffle furnace, the heating program is 10°C, the temperature balance time is 30min, the cooling method: water quenching, and the roasting temperature is 600°C.

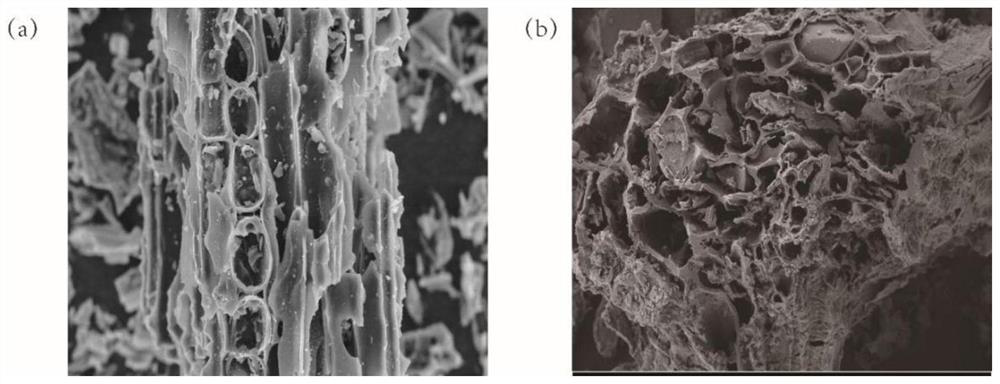

[0080] 2. Preparation of magnetic biochar:

[0081] The mango leaves were collected, air-dried and crushed into pieces to make a powder through a 10-mesh sieve.

[0082] Fully mixing the prepared magnetic particles, mango...

Embodiment 2

[0096] One, prepare magnetic biochar soil remediation agent of the present invention

[0097] Follow the steps below:

[0098] 1. Preparation of magnetic particles:

[0099] Weigh 100g of the iron tailings from which impurities and silt have been removed and crush them through a crusher, add 200ml of 0.01M HCl to wash the crushed iron tailings, then filter through a 100-mesh nylon sieve to obtain slag, and then put the washed slag into the programmed temperature riser Furnace roasting at 1000°C for 30 minutes, heating program 10°C, temperature balance time 20 minutes, cooling method: water quenching, cooling slag, and magnetic separation of roasted slag by a strong magnet to obtain magnetic particles.

[0100] 2. Preparation of magnetic biochar:

[0101] Weigh 10 g of the prepared magnetic particles, grind and mix them with 5 g of rice straw powder and 5 g of urea, then transfer them to a covered porcelain crucible and carbonize in a muffle furnace at 600 °C for 1 h (includi...

Embodiment 3

[0118] One, prepare magnetic biochar soil remediation agent of the present invention

[0119] Follow the steps below:

[0120] 1. Preparation of magnetic particles:

[0121] Weigh 100g of steel slag from which impurities have been removed and crush it with a crusher, add 200ml of 0.01M HCl to wash the crushed steel slag, then filter through a 100-mesh nylon sieve to obtain slag, and then put the washed slag into a temperature-programmed muffle furnace for 30 minutes at 600°C , heating program 20 ℃, temperature balance time 40min, cooling method: water quenching, cooling slag, magnetically separate the roasted slag through a strong magnet to obtain magnetic particles.

[0122] 2. Preparation of magnetic biochar:

[0123] 10 g of the prepared magnetic particles were weighed, ground and mixed with 6 g of rice straw powder and 4 g of urea, and then transferred to a covered porcelain crucible for carbonization in a muffle furnace at 600 °C for 1 h (including under oxygen-limited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com