High-nitrogen compound microbial fertilizer as well as preparation method and application thereof

A compound microorganism and microbial fermentation technology, which is applied in the field of high nitrogen compound microorganism fertilizer and its preparation, can solve the problems of difficulty in unifying and coordinating culture temperature and culture period, difficult unification of culture temperature and culture time, and difficulty in guaranteeing the synergy of strains. To achieve the effect of shortened fermentation cycle, wide source of raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of a microbial fermentation agent, the preparation method comprising the following steps: inoculating Paenibacillus polymyxa, Bacillus subtilis, and Paenibacillus jelly-like into the microbial fermentation medium for fermentation and culture , the microbial fermentation inoculant is obtained after the fermentation is finished.

[0030] Paenibacillus polymyxa (Paenibacillus polymyxa) is a kind of spore-forming Gram-positive bacteria, which has both disease-preventing and growth-promoting effects on plants without pathogenicity. Most strains of Paenibacillus polymyxa tested under anaerobic conditions can fix nitrogen, and can prevent and control a variety of soil-borne diseases and foliar diseases caused by pathogenic bacteria belonging to 2 genera of Oomycota, 24 genera of Fungi and 6 genera of Bacteria. disease. Polymyxins produced by Paenibacillus polymyxa disrupt the permeability of the plasma membrane of Gram-...

Embodiment 1

[0070] The screening of embodiment 1 microbial strain agent

[0071] By carrying out the screening experiment of nitrogen fixation, phosphorus and potassium decomposition on the existing bacterial strains of the applicant, the nitrogen fixation, phosphorus and potassium decomposing strains are screened out.

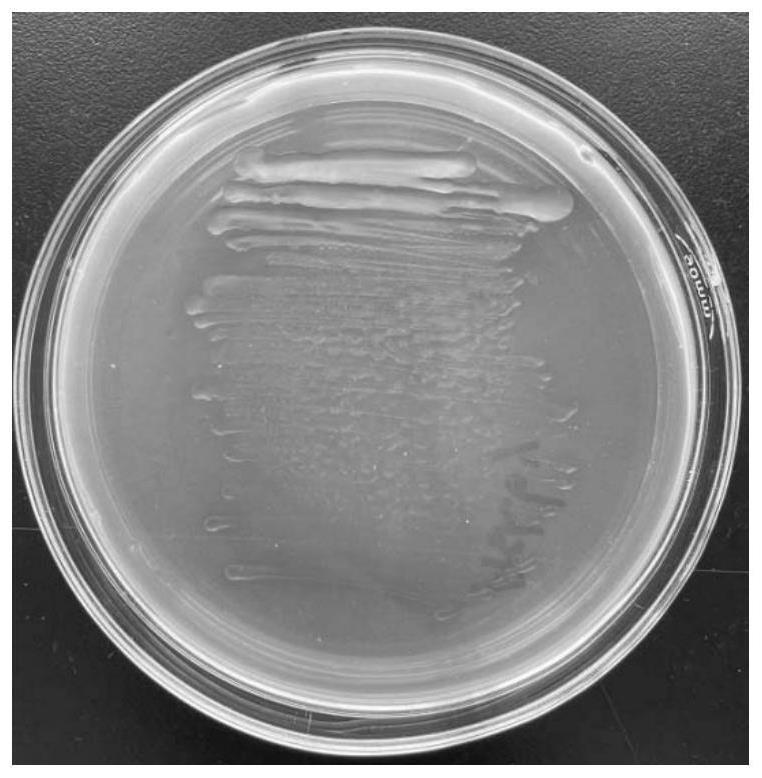

[0072] 1.1 Preliminary screening of nitrogen-fixing bacteria

[0073] The initial screening of nitrogen-fixing bacteria adopts the growth rate method. The isolated nitrogen-fixing bacteria are activated on nutrient agar medium, and then a ring of activated bacteria is transplanted into a test tube (18*180mm) containing Ashby liquid medium with an inoculation loop. The tube was filled with 5 mL of culture solution, and the control was the culture solution without strains, and repeated 3 times. 30°C, 120r / min shaking culture for 36h, measure the OD of each bacterial solution 600 value, and according to OD 600 The value size selects the strain.

[0074] 1.2 Re-screening ...

Embodiment 2

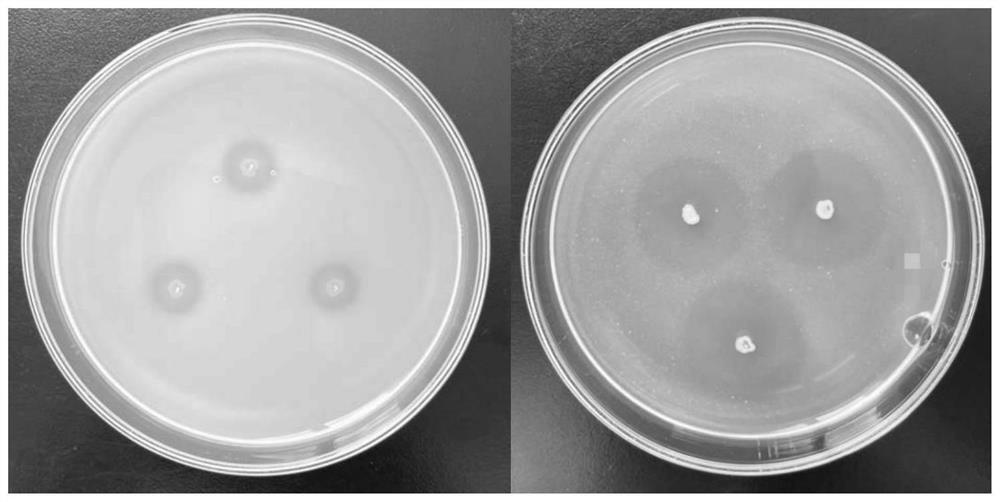

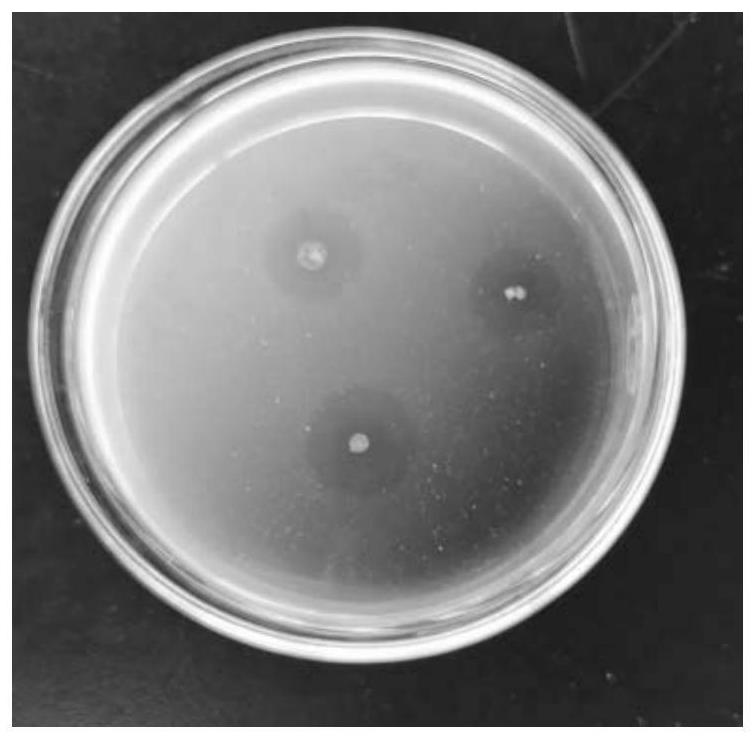

[0100] Antagonism test of embodiment 2 bacterial strain

[0101] Inoculate the activated phosphate solubilizing bacteria, potassium solubilizing bacteria and nitrogen fixing bacteria into sterilized liquid medium (100mL / 250mL) respectively, culture them in a 30°C incubator for 5 days, absorb the fermentation broth and observe the growth of the strains under a high power microscope Are there any exceptions. Test result shows, each single bacterial strain grows well and does not have rejection phenomenon, can symbiosis, does not take place non-antagonistic reaction ( Figure 5 ), indicating that these three bacteria can be mixed cultured. The composition of the liquid culture medium mentioned above is composed of 0.5% of beef extract powder, 1% of peptone, 0.5% of sodium chloride, 1.3-20% of agar, and pH 7.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com