Photo-assisted wide-temperature solid-state lithium air battery and preparation method thereof

An air battery and solid-state lithium technology, applied in fuel cells, battery electrodes, fuel cell-type half-cells and primary battery-type half-cells, etc. problems, to avoid side reactions, promote reaction kinetics, and reduce interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

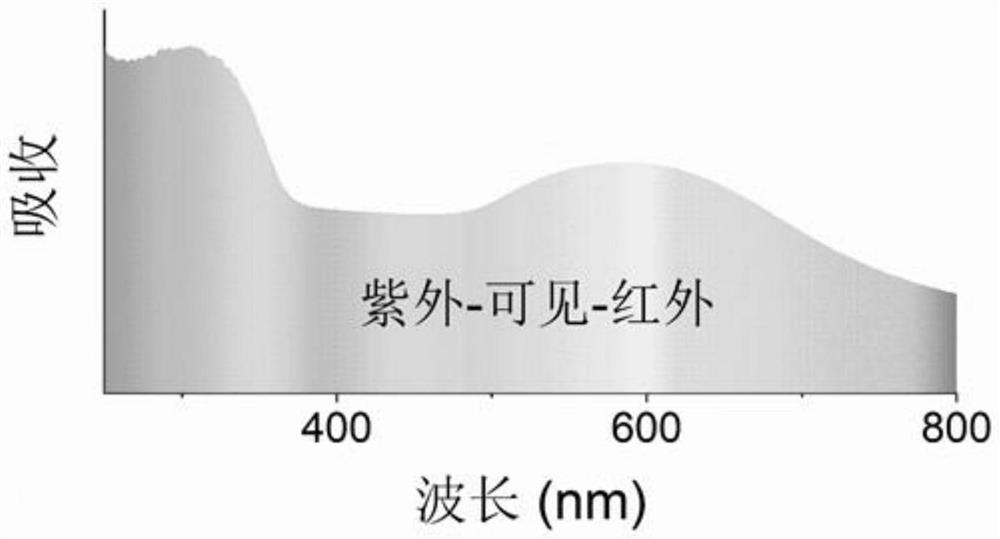

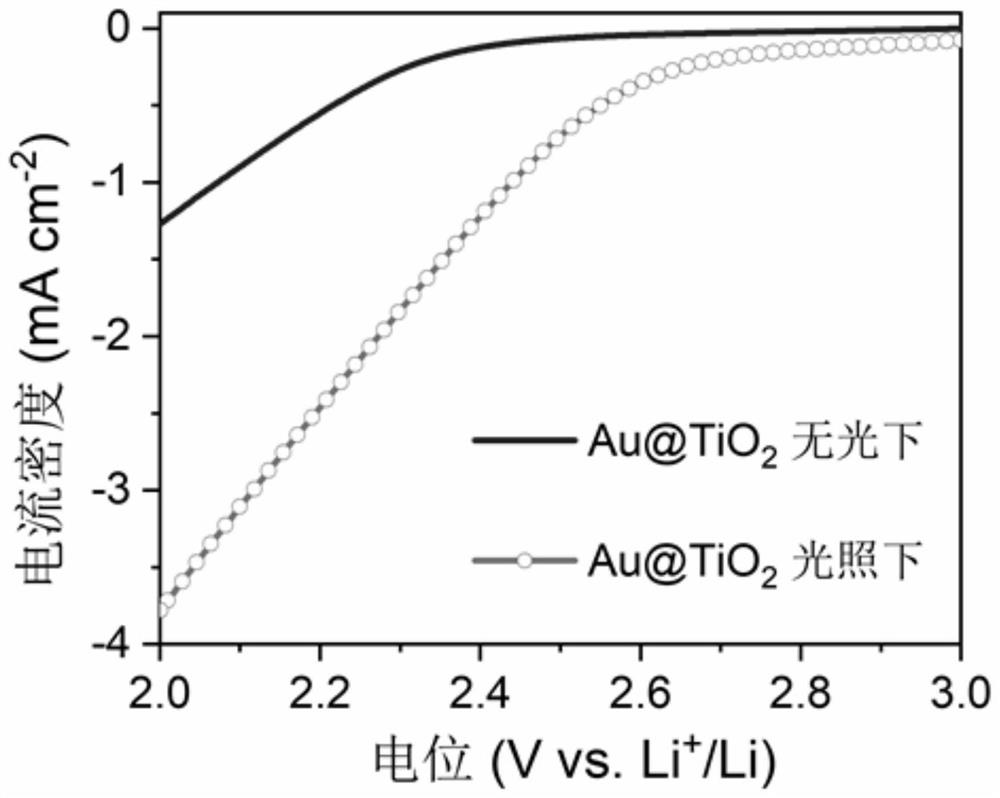

[0084] Preparation of Au@TiO 2 Photocathode:

[0085] 1. Take 0.4175mL of ammonia water, 0.91mL of water, and 5mL of isopropyl titanate and quickly add them to a mixed solution of 150mL of ethanol and 100mL of acetonitrile, stir at a constant speed for 6 hours, centrifuge, and dry to obtain a white powder;

[0086] 2. Dissolve 1.5g of the obtained white powder in 30mL of water, add 0.1167g of ammonium fluoride and 0.15g of polyvinylpyrrolidone (molecular weight 10K) in sequence, transfer to the reaction kettle, store at 110°C for 4 hours, and add 0.36mL of three Ethylamine and 2.25mL acetic acid, stirred evenly, transferred to the reaction kettle, kept at 85°C for 24h, centrifuged, washed with 1mM sodium hydroxide, washed with water and dried to obtain a white sea urchin-shaped spherical shell titanium dioxide powder;

[0087] 3. Disperse 1.5 g of sea urchin-shaped spherical shell titanium dioxide white powder in 50 mL of aqueous solution, add 1 mL of 1 mM chloroauric acid so...

Embodiment 2

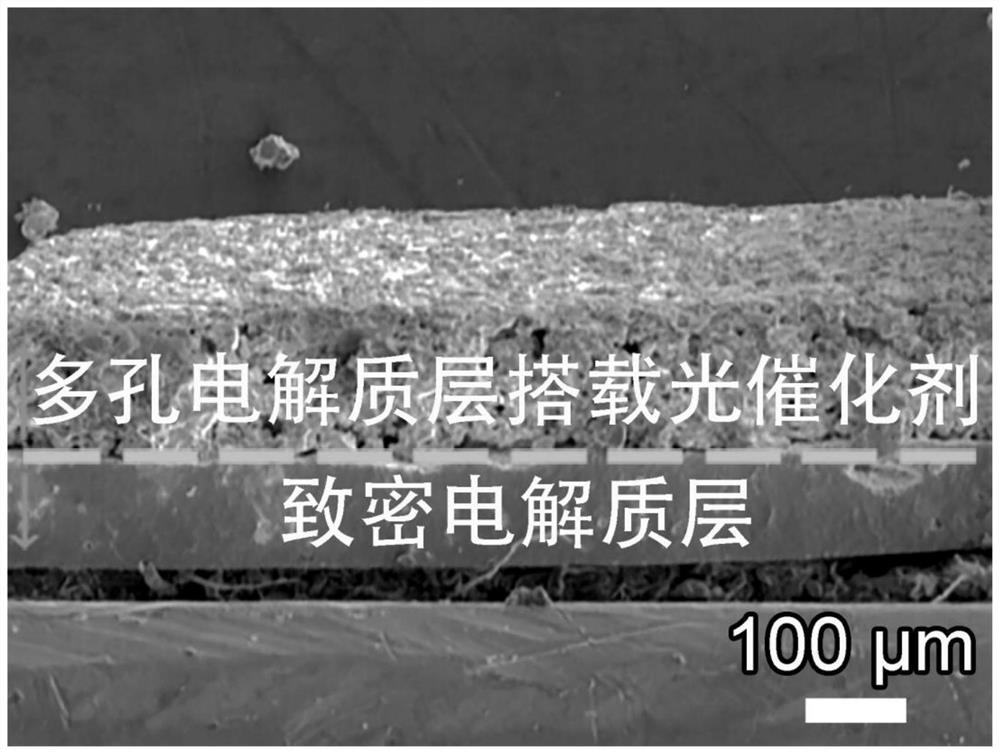

[0098] Preparation of the integrated double-layer ATLL frame:

[0099] 1. Dissolve 0.78g of germanium oxide in 5mL of ammonia water (content 25%) and stir at 60°C to form a homogeneous solution; according to Li3 AlGe 3 (PO 4 ) 6 The lithium carbonate (excessive 10%) that the stoichiometric ratio of equation drops into, aluminum nitrate nonahydrate, ammonium dihydrogen phosphate are dissolved in 175mL 0.2M citric acid aqueous solution, form homogeneous solution;

[0100] 2. Mix the two solutions and add 2mL of ethylene glycol to form a sol-gel at 90°C. The gel was stored at 170°C for 24 hours to obtain.

[0101] 3. Anneal the obtained brown powder at 500°C and 900°C for 6 hours to obtain white powder LAGP;

[0102] 3. Grind LAGP and starch at a weight ratio of 2:1, add the mixed powder and pure LAGP powder in sequence, spread out layer by layer in the mold, and pressurize at 30MPa for 6 minutes. Annealed at 900 °C to obtain a bilayer integrated LAGP framework. ;

[0103]...

Embodiment 3

[0114] Preparation of light-assisted wide-temperature solid-state lithium-air batteries:

[0115] From top to bottom, the positive electrode current collector with a diameter of 10mm window, the integrated double-layer ATLL frame, and the negative electrode lithium sheet are assembled in the 2025 battery. The light-assisted wide-temperature solid-state lithium-air battery was subjected to xenon lamp irradiation tests at room temperature, dry ice, and an oven (150 degrees Celsius).

[0116] The light-assisted wide-temperature solid-state lithium-air battery prepared in Example 3 of the present invention was characterized.

[0117] see Figure 7 , Figure 7 The first charge and discharge voltage curve of the light-assisted solid-state lithium-air battery prepared for the present invention at room temperature.

[0118] Depend on Figure 7 It can be seen that under light conditions, the light-assisted solid-state lithium-air battery can achieve an ultra-low polarization of 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com