Application of supported catalyst in continuous preparation of penicillin sulfoxide ester

A supported catalyst, penicillin technology, applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of difficult removal of catalyst metabolites, inability to recycle, increase production costs, etc., to reduce synthesis and purification. Difficulty, fast reaction rate, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

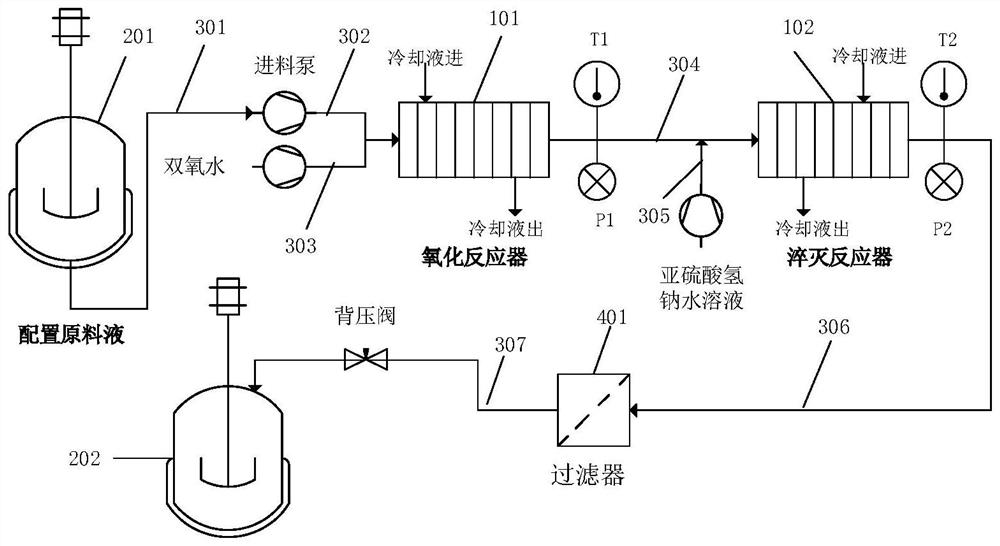

Method used

Image

Examples

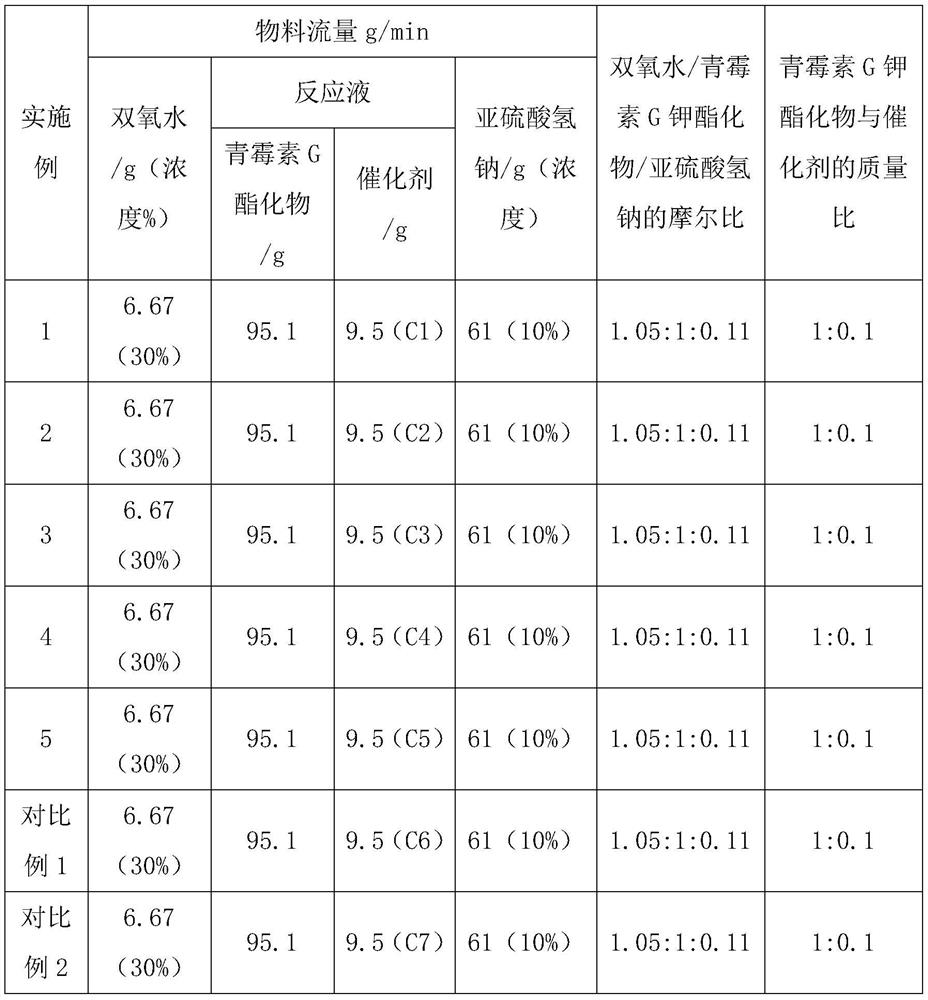

Embodiment 1-13

[0039] 1. Penicillin G potassium ester synthesis:

[0040]4L of dichloromethane, 2Kg of penicillin G potassium, 1.165Kg of p-nitrobenzyl bromide and 100g of triethylbenzyl ammonium chloride were successively added into a 10-liter glass reactor. Stir and heat up, reflux for 6-7 hours, HPLC tracking, after the reaction is completed, cool down to room temperature, add 2L of water, stir evenly, let stand for 30 minutes, and release the organic phase. The aqueous phase was extracted twice with 0.5 L of dichloromethane, the organic phases were combined, and the organic phase was rinsed twice with 0.5 L of water, and the rinsed organic phase was set aside. The concentration of penicillin G potassium ester was 27.66%.

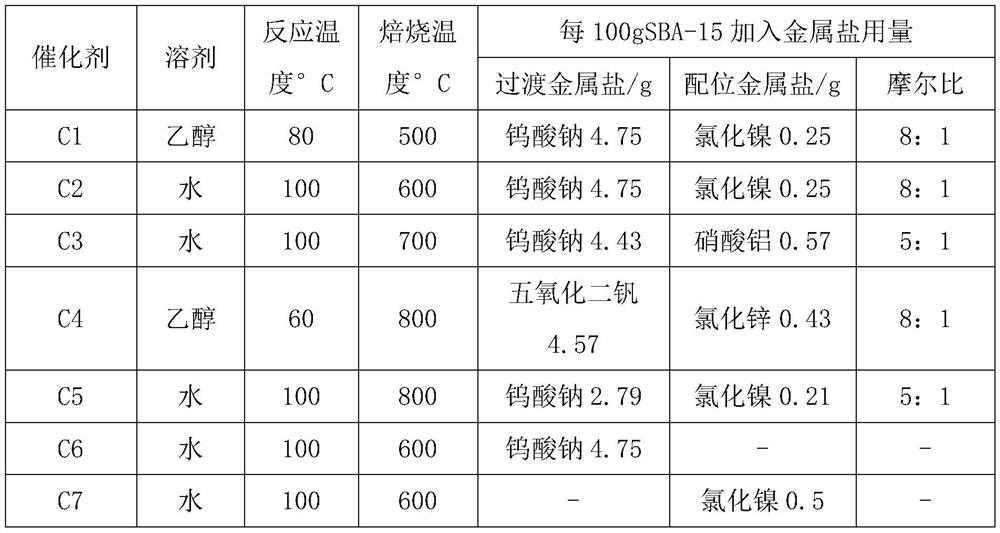

[0041] 2. Preparation of catalyst:

[0042] The supported catalyst is prepared by the impregnation method. Under the protection of nitrogen, the transition metal salt and the coordination metal are added and dissolved in the solvent (the amount of solvent should be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com