Method and apparatus for altering material using ion beams

a technology of ion beams and ion beams, which is applied in the field of material modification, can solve the problems of brittle and hard materials, high cost of ion implantation and laser glazing, and inability to scale to common industrial use, and achieves less direct adhesive wear, reduce the amount of self-abrasive wear, and reduce the size of abrasive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

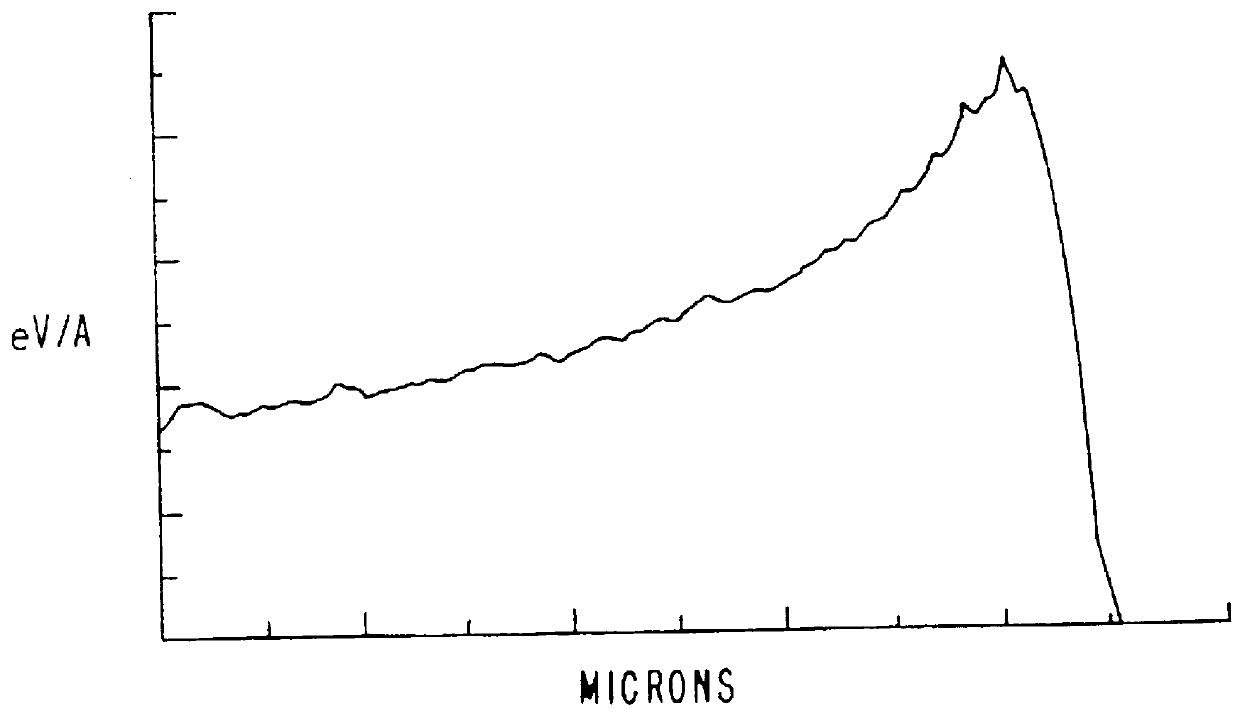

A sample of nominally pure Cu was etched in 1 molar nitric acid for one minute. Scanning electron microscopy (SEM) analysis of the resulting surface showed a roughened surface with hillocks and "sharp" features approximately 3-5 .mu.m in height. These samples were treated using a single pulse of an ion beam generated using a RHEPP prototype power source and a flashover ion source. (In a flashover ion source an electrical discharge volatilizes the surface of a polymer, resulting in the generation of mixed carbon and hydrogen ions.) The beam kinetic energy was 1.0 MeV, the pulse width was approximately 60 ms, and the total pulse energy density at the treated surface was .about.3J / cm.sup.3.

Post-treatment SEM analysis revealed a smoother surface with more gradual changes in surface configuration and an average surface roughness of .about.0.5 .mu.m. In this example the Cu surface was molten for .about.500 ns. The driving force of surface tension during this period was clearly sufficient ...

example 2

A piece of Ti-6Al-4V alloy (a common machinable titanium alloy) was machined using conventional precision machining techniques, leaving a nominally flat surface with machining marks producing a surface roughness of .about.5 .mu.m. This surface was treated by exposure to four pulses, each pulse having a beam kinetic energy of .about.3.0-0.4 MeV, a duration of .about.400 ns, and a total pulse energy density of .about.7 J / cm.sup.2. SEM analysis of the treated surface revealed surface roughness had been reduced to .about.0.1 .mu.m. The time the metal surface was liquid was again some 250-500 ns, suggesting that the effect of multiple pulses in the smoothing process is additive, i.e., that more pulses give a smoother surface.

example 3

One side of an alumina (Al.sub.2 O.sub.3 ceramic) sample was polished using submicron abrasive grit suspensions. Following characterization of the surface with an SEM, the polished surface was subjected to a single ion pulse having a beam kinetic energy of .about.1.0 MeV, a beam duration of .about.60 ns, and a total pulse energy density of .about.10 J / cm.sup.2. Post-treatment analysis showed evidence for melting and resolidification resulting in reduction of surface porosity. There remained, however, some microcracking on a 0.1 .mu.m size scale. It is considered likely that further treatment would yield a uniformly smooth surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com