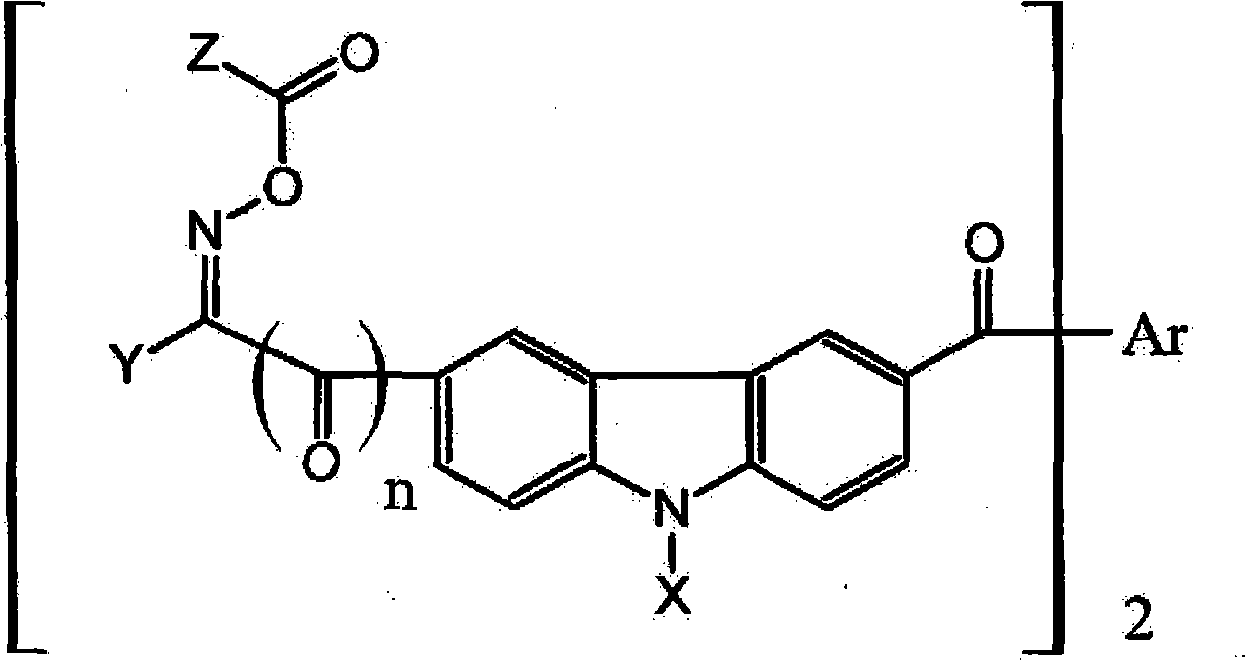

Photo-curable and heat-curable resin composition

A resin composition and photocurable technology, which is applied in the field of photocurable thermosetting resin composition, can solve problems such as difficulty in removing impurities, and achieve the effects of improving hydrophobicity, excellent insulation reliability, and improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

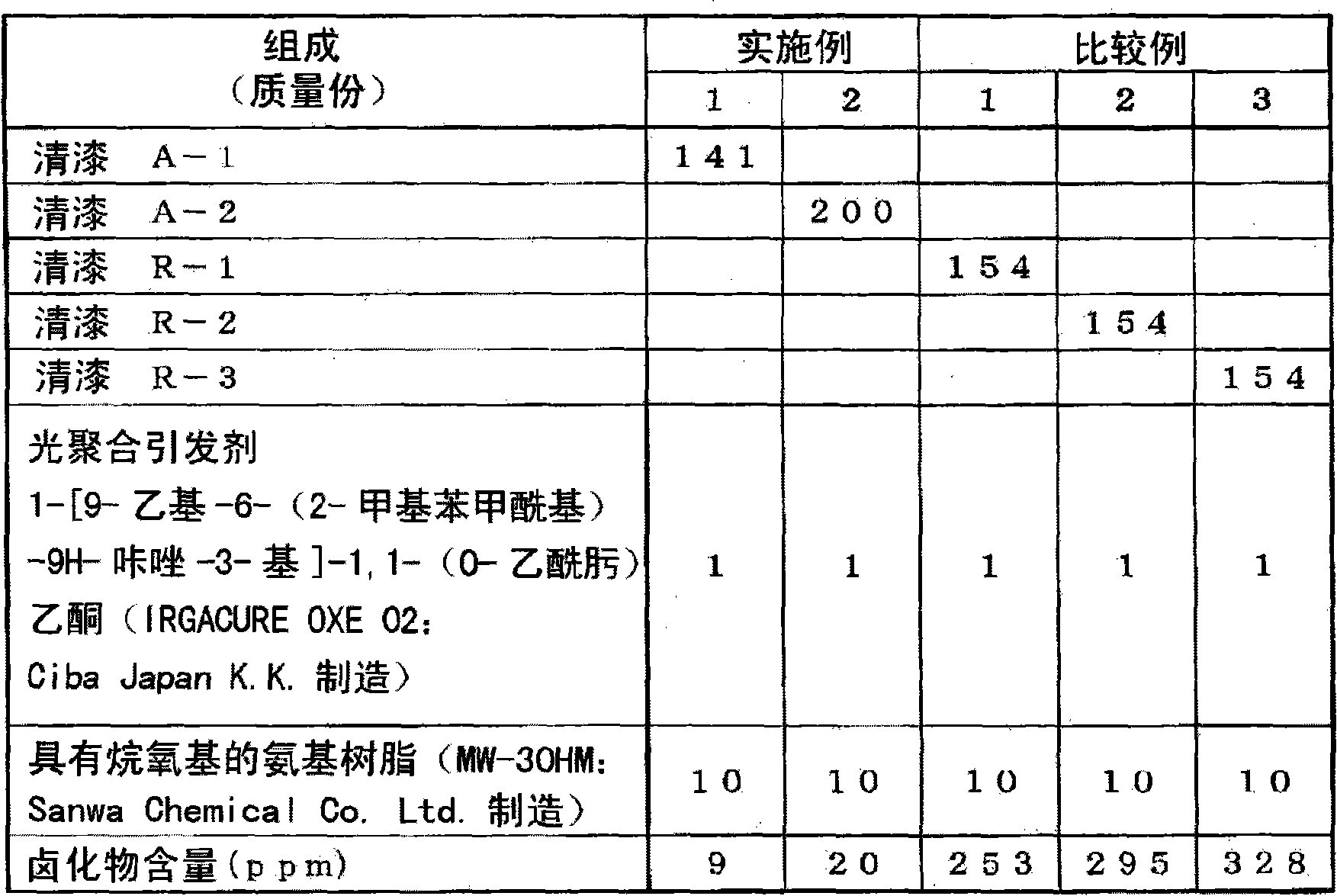

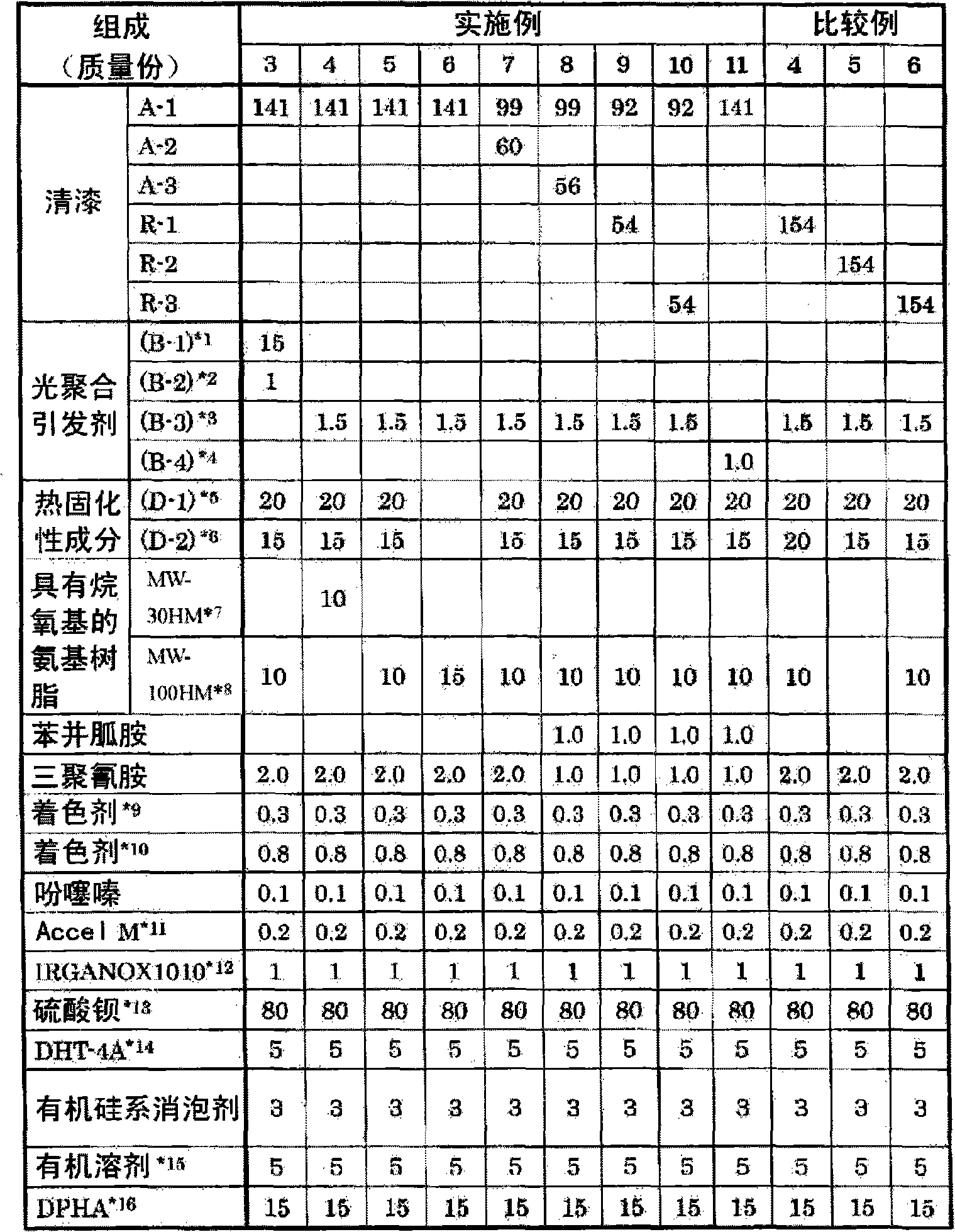

[0167] Examples and comparative examples are shown below to specifically describe the present invention, but the present invention is not limited to the following examples. In addition, the following "parts" and "%", unless otherwise specified, all refer to quality standards.

Synthetic example 1

[0169] In an autoclave equipped with a thermometer, a nitrogen introduction device, an alkylene oxide introduction device, and a stirring device, 119.4 g of novolac type cresol resin (manufactured by Showa Polymer Corporation, trade name "Shonol CRG951", OH equivalent: 119.4) is added, 1.19 g of potassium hydroxide and 119.4 g of toluene were replaced with nitrogen in the system while stirring, and heated. Then, slowly add 63.8g of propylene oxide dropwise, at 125~132℃, 0~4.8kg / cm 2 React for 16 hours. Then, it was cooled to room temperature, and 1.56 g of 89% phosphoric acid was added and mixed in the reaction solution to neutralize potassium hydroxide to obtain a novolac type cresol resin epoxy with 62.1% non-volatile content and 182.2 g / eq. of hydroxyl value. Propane reaction liquid. This is a substance in which 1.08 moles of alkylene oxide are added on average per 1 equivalent of phenolic hydroxyl group.

[0170] Next, 293.0 g of the obtained novolak type cresol resin alkyl...

Synthetic example 2

[0172] In a 5-liter separable flask equipped with a thermometer, a stirrer, and a reflux condenser, 1245 g of polycaprolactone diol (PLACCEL208 manufactured by DDAICEL CHEMICAL INDUSTRIES, LTD., molecular weight 830) as a polymer polyol, and 201 g were put into Dimethylolpropionic acid as a dihydroxy compound having a carboxyl group, 777 g of isophorone diisocyanate as a polyisocyanate, and 119 g of 2-hydroxyethyl acrylate as a (meth)acrylate having a hydroxyl group, and 0.5 g each Of p-methoxyphenol and di-tert-butyl-hydroxytoluene. While stirring, it was heated to 60°C to stop, and 0.8 g of dibutyltin dilaurate was added. If the temperature in the reaction vessel starts to decrease, heat it again, continue stirring at 80°C, and confirm the absorption spectrum of the isocyanate group in the infrared absorption spectrum (2280cm -1 When) disappears, the reaction is stopped, and a viscous liquid urethane acrylate compound is obtained. Carbitol acetate was used to adjust to non-v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com