Ceramic membrane, application of ceramic membrane to battery and battery comprising ceramic membrane

A ceramic diaphragm and diaphragm material technology, applied in the field of electrochemistry, can solve problems affecting the performance of ceramic diaphragms, powder dropping, and poor wetting ability of diaphragm substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

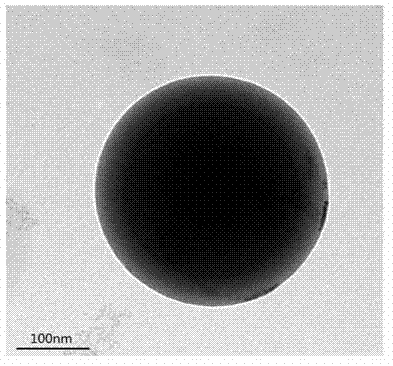

Embodiment 1

[0042] Add 30ml of tetraethyl orthosilicate to 350mL of absolute ethanol at room temperature, then quickly add 30ml of water and 12ml of 14mol / L ammonia water mixture, stir and react at a speed of 200r / min for 3h to obtain a silica particle dispersion, two Silicon oxide particles are around 400nm. in N 2 Under the protection of air, add the above-mentioned nano-silica particle dispersion, deionized water and methyl acrylate monomer into the reactor with condensing device, stir for 60 minutes and start to heat up, and add an appropriate amount of persulfuric acid at 75°C Ammonium, after constant temperature for 6h, the temperature is raised to 85°C to continue the reaction for 60min, and then the temperature is lowered to obtain a silica / methyl acrylate core-shell composite. Characterized by transmission electron microscopy, the thickness of the shell layer can be controlled by adjusting the input amount of methyl acrylate monomer. 2nm-1μm. Take 4g of core-shell complex and 1...

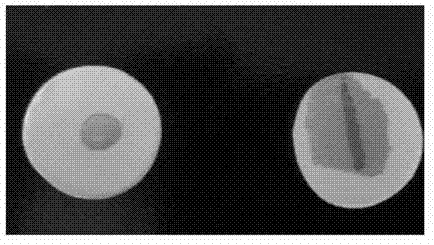

Embodiment 2

[0051]Mix 1000ml of deionized water, 10g of titanium dioxide and 0.1g of sodium dodecylbenzenesulfonate with a particle size of 50nm in a three-necked flask with a capacity of 2000ml, under nitrogen protection, mechanically stir for 1 hour, add 0.3g of ammonium persulfate and 0.3g sodium sulfite, heat up to 80°C, add 15g butyl methacrylate, react for 2 hours, add 1.5g polyethylene glycol dimethacrylate with a molecular weight of 1500 for chemical crosslinking, continue to react for 2 hours and then stop After the reaction, the obtained product is centrifuged, washed three times with ethanol and water respectively, and dried at room temperature under vacuum conditions to obtain a titanium dioxide / butyl methacrylate core-shell complex. Take 8g of core-shell compound and 2g of polyvinylidene fluoride-hexafluoropropylene (binder) and disperse them in 100ml of acetone. 2 Coated on the polypropylene diaphragm, and after drying, the ceramic diaphragm was obtained.

Embodiment 3

[0053] Mix 3000ml of deionized water, 100g of zirconium dioxide and 1g of sodium dodecylbenzenesulfonate with a particle size of 10 μm in a three-necked flask with a capacity of 5000ml, under nitrogen protection, mechanically stir for 1 hour, add 3g of ammonium persulfate and 3g sodium sulfite, be warming up to 80 DEG C, add 100g ethylene glycol methyl methacrylate, stop reaction after reacting for 4 hours, the product that obtains is centrifuged, washes respectively three times with ethanol and water, dries under room temperature, vacuum condition, A zirconium dioxide / polyethylene glycol methyl methacrylate core-shell composite was obtained. Take 10g of core-shell composite, 0.2g of hydroxymethyl cellulose and 0.3g of styrene-butadiene rubber and disperse them in 100ml of water, coat them on a 20cm×6m polyethylene diaphragm with a small coating machine, and obtain a ceramic diaphragm after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com