Preparation method for hydrophilia polyvinylidene fluoride hollow fiber membrane

A polyvinylidene fluoride and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as adsorption, solve easy agglomeration, improve hydrophilic persistence, and improve compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

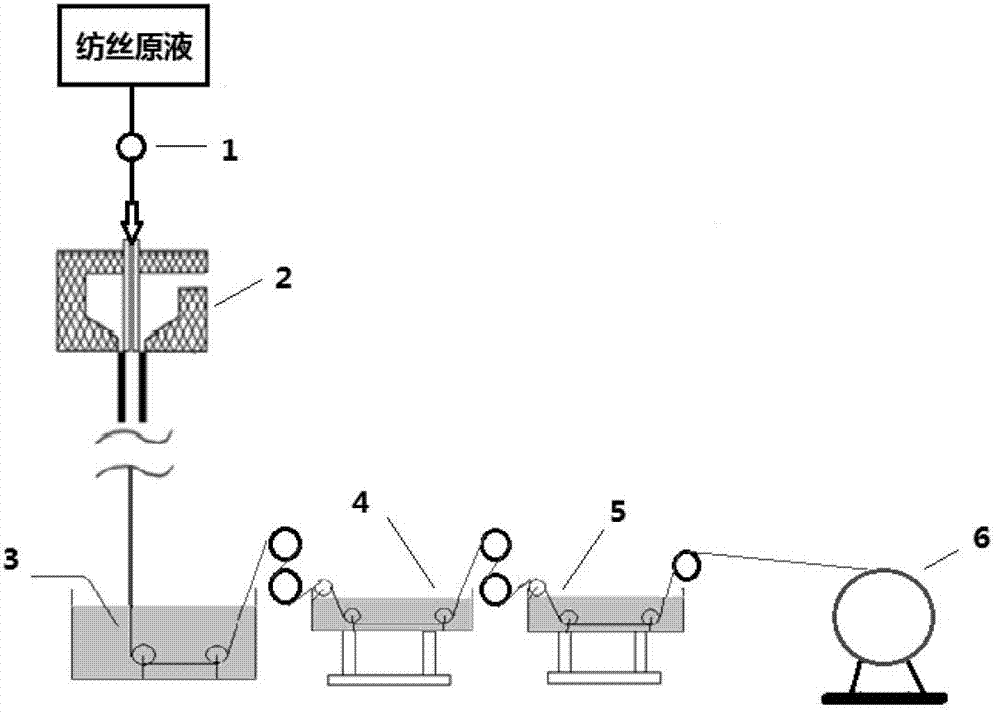

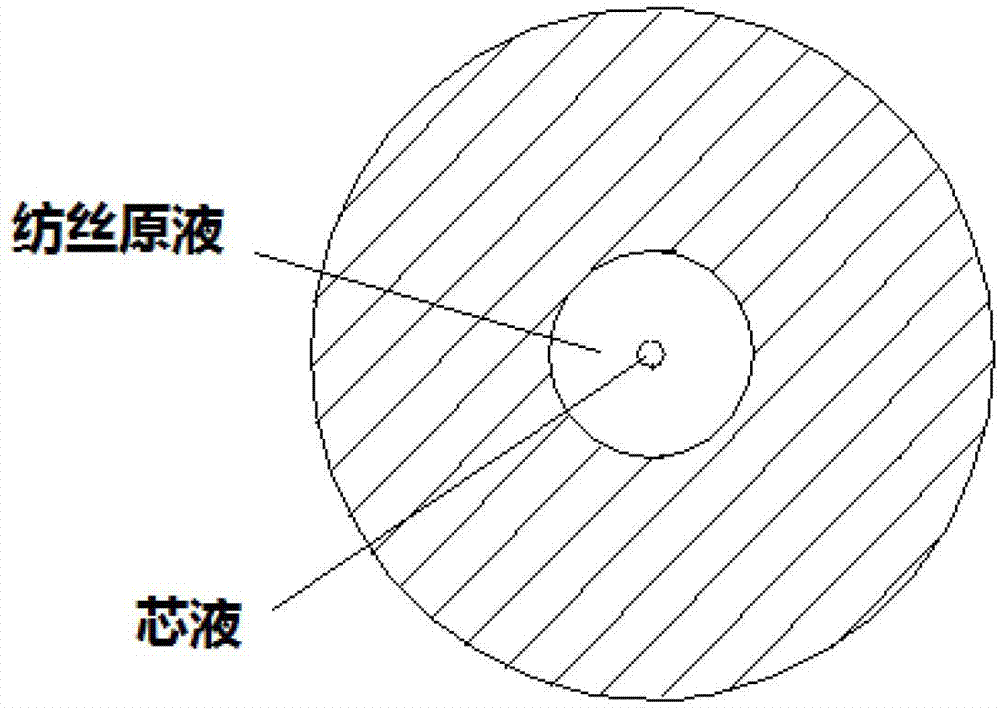

Method used

Image

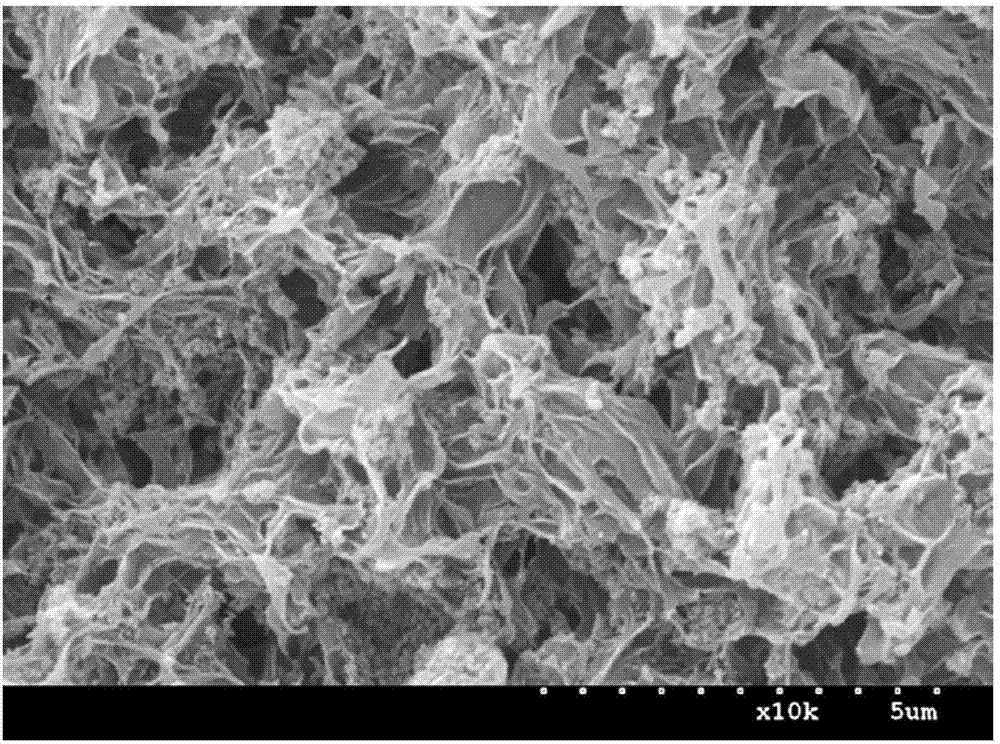

Examples

Embodiment 1

[0047] (1) Dissolve the silane coupling agent (KH570) in water and ethanol solution with a volume ratio of 1 / 9, and prepare a solution with a mass concentration of 9.0%. SiO 2 After the addition of the powder (2 parts), the temperature was gradually raised to 90° C., and the stirring was continued for 3.0 h. Cool down to room temperature and then dry.

[0048] (2) 20 parts of MPEG and 0.161 parts of phase transfer agent tetrabutylammonium bromide (TBAB), dissolved in 50 parts of toluene at 50°C, 14 parts of sodium hydroxide (NaOH), added 4-vinyl under vigorous stirring 0.763 parts of benzyl chloride, the temperature was raised to 65°C, after 5 hours of reaction, cooled to room temperature, 100 parts of extractant dichloromethane was added, the solution was filtered, and then the dichloromethane was removed by rotary evaporation. The product was purified by repeated dissolution with dichloromethane and precipitation in anhydrous ether. The product was dried in a vacuum oven ...

Embodiment 2

[0052] (1) Dissolve the silane coupling agent (A-171) in water and ethanol solution with a volume ratio of 1 / 8, and prepare a solution with a mass concentration of 8.0%. After it is completely dispersed, slowly add it dropwise and stir at high speed at room temperature Quantitative TiO 2 After the addition of the powder (3 parts), the temperature was gradually raised to 100° C., and the stirring was continued for 4.0 h. Cool down to room temperature and then dry.

[0053] (2) 25 parts of MPEG and 0.363 parts of phase transfer agent tetrabutylammonium bromide (TBAB), dissolved in 50 parts of benzene at 55 °C, 60 parts of sodium hydroxide (NaOH), added 4-vinyl under vigorous stirring 19 parts of benzyl chloride, the temperature was increased to 80°C, after 6 hours of reaction, cooled to room temperature, 250 parts of extractant dichloromethane was added, the solution was filtered, and then the dichloromethane was removed by rotary evaporation. The product was purified by repea...

Embodiment 3

[0057] (1) Dissolve the silane coupling agent (KH570) in water and ethanol solution with a volume ratio of 1 / 6, and prepare a solution with a mass concentration of 7.0%. Al 2 o 3 After the addition of the powder (1 part), the temperature was gradually raised to 100° C., and the stirring was continued for 3.0 h. Cool down to room temperature and then dry.

[0058] (2) 30 parts of MPEG and 0.256 parts of phase transfer agent tetrabutylammonium bromide (TBAB), dissolved in 60 parts of toluene / dichloromethane (mass ratio 1:9) at 50 ° C, sodium hydroxide (NaOH) 60 Parts, 15.2 parts of 4-vinylbenzyl chloride was added under vigorous stirring, the temperature was raised to 62 ° C, after 5.5 hours of reaction, cooled to room temperature, 280 parts of extractant dichloromethane was added, and the solution was filtered, then rotary evaporation to remove dichloromethane Chloromethane. The product was purified by repeated dissolution with dichloromethane and precipitation in anhydrous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Bubble point pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com