Novel synthesis method for 4,4,4-trifluorobutanol

A technology of trifluorobutanol and a synthesis method, which is applied in chemical instruments and methods, preparation of hydroxy compounds, preparation of organic compounds, etc., can solve the problems of complicated operation, difficult processing, low yield and the like, and achieves cheap and easy-to-obtain raw materials, The effect of simple post-processing and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

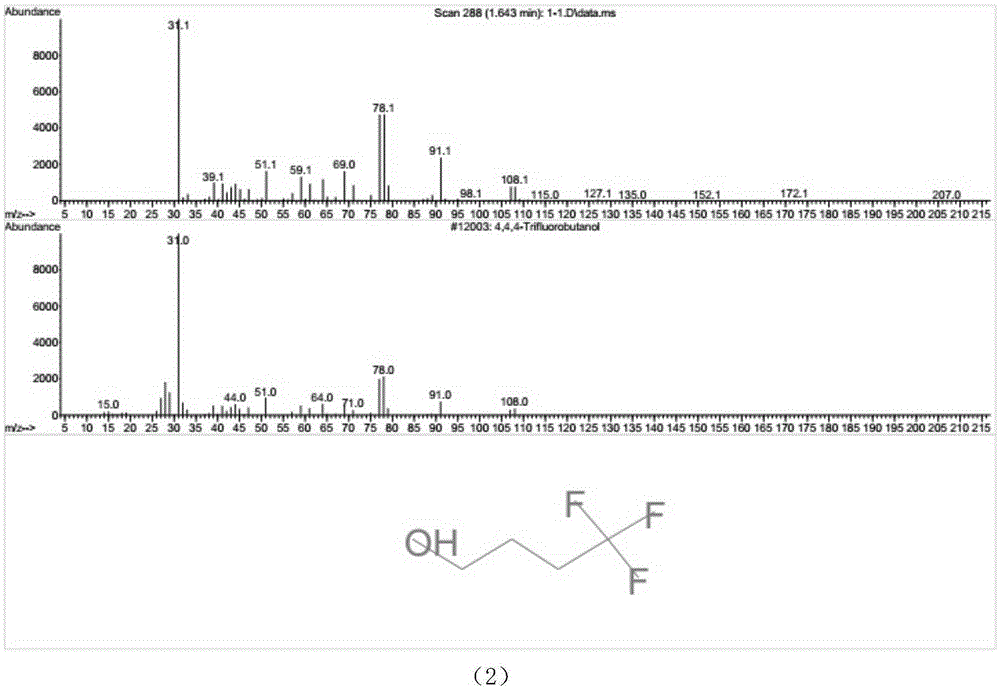

Image

Examples

Embodiment 1

[0052] step 1

[0053]

[0054]Add 900ml of methanol into a 2L three-neck flask, add 160.17g of diethyl malonate to dissolve, add 81.03g of sodium methoxide at 25°C, raise the temperature to 40°C, and add 2,2,2-trifluoro-p-toluenesulfonic acid in batches A total of 254.22g of ethyl ester was added. After the addition, the reaction was maintained at a temperature of 65°C and monitored by GC until the reaction was complete. After the reaction was complete, it was concentrated under reduced pressure. The pH of the concentrated system was adjusted to pH=6-7, and 500ml of ethyl acetate was added to extract After drying the organic phase, the solvent was recovered to obtain 238.43 g of 2-(2,2,2-trifluoroethyl)-diethyl malonate, the GC content was 97.82%, and the yield was 96.3%.

[0055] step 2

[0056]

[0057] Add 600ml of DMSO to a 1L three-neck flask, add 123.79 (97.82%) g of 2-(2,2,2-trifluoroethyl)-diethyl malonate, add 40g of sodium chloride and 123.79ml of water at 25...

Embodiment 2

[0065] The difference between the preparation process and Example 1 is:

[0066] In step 1, the basic catalyst is sodium ethylate, and the extraction solvent is dichloromethane, with a yield of 95.84%;

[0067] In step 2, the reaction solvent is DMF, the reaction temperature is 120°C, and the yield is 93.17%;

[0068] In step 3, the reaction solvent is methanol, and the yield is 76.24%;

Embodiment 3

[0070] The difference between the preparation process and Example 1 is:

[0071] In step 1, the molar ratio of diethyl malonate to ethyl 2,2,2-trifluoro-p-toluenesulfonate is 1:1.2, and the yield is 96.47%;

[0072] In step 2, the salt is calcium chloride, and the weight ratio between it and ethyl 2,2,2-trifluorotoluenesulfonate is 1:0.2, the reaction time is 16 hours, and the yield is 94.38%;

[0073] In step 3, the reducing agent is potassium borohydride, and the molar ratio of it to ethyl 4,4,4-trifluorobutyrate is 1.2:1, and the yield is 80.36%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com