Method for synthesizing cyclic carbonate through polyionic liquid nanometer catalysis cycloaddition reaction

A polyionic liquid, cyclic carbonate technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems to be further improved and improved, etc., Achieve thermal stability and good solvent resistance, good reproducibility, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

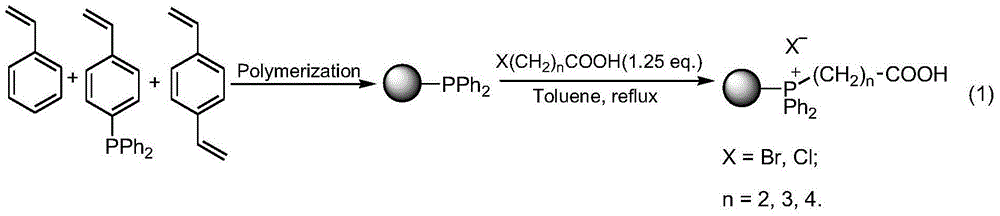

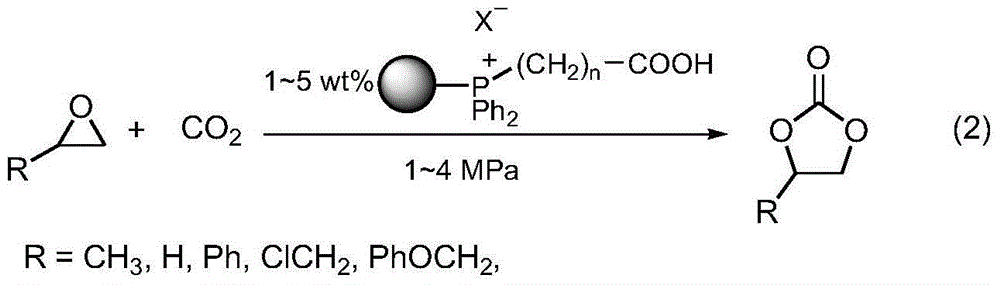

[0021] Embodiment 1 synthetic catalyst

[0022]A mixed solution containing 30% of 4-diphenylphosphine styrene, 60% of styrene, 10% of divinylbenzene and 1.0% of azobisisobutyl cyanide As the dispersed phase, the aqueous solution containing 1.0% polyethylene glycol and 0.03% sodium lauryl sulfate is the continuous phase, wherein the dispersed phase is dispersed through a metal braided membrane with a 4-stage pore size of 1.0 μm to form microemulsion droplets; then, Raise the temperature to 75°C to thermally initiate free radical polymerization to obtain phosphine-functionalized polymer nanoparticles. The average particle size of the nanoparticles is 110 nm, and the dispersion index is 15%. Add it into a three-necked round-bottomed flask with a reflux condenser, heat and reflux for 24 hours to prepare a carboxylic acid quaternary phosphine polyionic liquid nanocatalyst.

Embodiment 2

[0024]

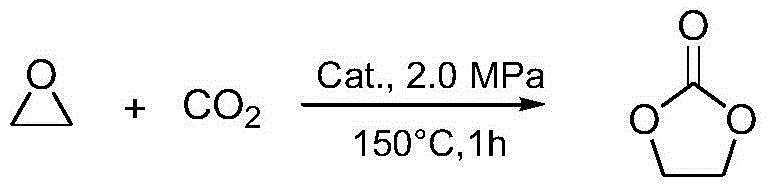

[0025] Add 20mg of carboxylic acid quaternary phosphine polyionic liquid nanocatalyst and 14.3mmol of ethylene oxide into a 75mL stainless steel autoclave equipped with a magnet, heat it to 150°C with an electric heating furnace, and then feed 2.0MPaCO into the reactor 2 After 1 hour of reaction, when the pressure no longer drops, the reaction is considered to be terminated, stop heating, cool to room temperature, and release unreacted CO 2 Gas gets back to normal pressure; Finally, in autoclave, add internal standard thing biphenyl, utilize Agilent gas chromatograph 6820GCTCD detector to carry out quantitative analysis to it, the styrene carbonate yield that obtains is 99.9%, and its selectivity is 99.9%. %.

Embodiment 3

[0027]

[0028] Add 10mg of carboxylic acid quaternary phosphine polyionic liquid nanocatalyst and 14.3mmol of propylene oxide into a 75mL stainless steel autoclave equipped with a magnet, heat it to 150°C with an electric heating furnace, and then feed 2.0MPaCO into the reactor 2 After 4 hours of reaction, stop the reaction when the pressure in the autoclave no longer drops, cool to room temperature, slowly open the autoclave and bring it back to room temperature; finally, add internal standard biphenyl to the autoclave, and use Agilent gas chromatograph A 6820GCTCD detector was used for quantitative analysis, and the yield of propylene carbonate was 99.0%, and its selectivity was 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com