Silicon nitride powder for solar polysilicon ingot casting and preparation method thereof

A technology of silicon nitride powder and silicon nitride micropowder is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc. Small coefficient, promoting directional growth and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

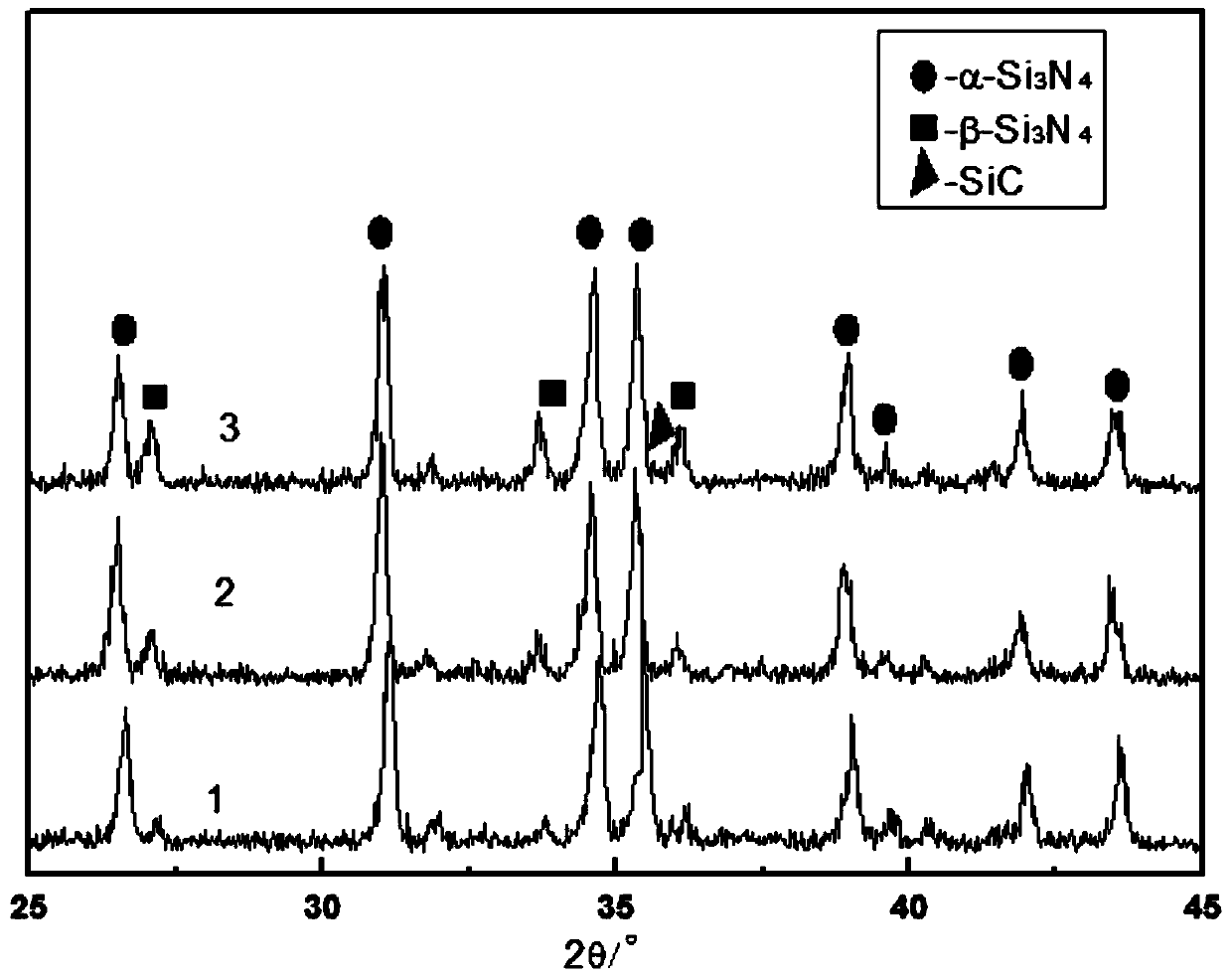

Image

Examples

Embodiment 1

[0027] 1) Take silicon powder, silicon nitride powder and ammonium carbonate in proportion, wherein the weight of silicon powder accounts for 30% of the total weight of silicon powder, silicon nitride powder and ammonium carbonate, and the weight of silicon nitride powder accounts for 30% of the total weight of silicon powder. , 60% of the total weight of silicon nitride powder and ammonium carbonate, and the weight of ammonium carbonate accounts for 10% of the total weight of silicon powder, silicon nitride powder and ammonium carbonate,

[0028] The purity of the silicon powder is ≥99.99%, the particle size is 0.1-25 μm, and the median particle size is 3.5 μm;

[0029] The silicon nitride powder has a purity ≥ 99.99%, an α-phase content of 90%, a particle size of 0.1-50 μm, and a median particle size of 5.0 μm;

[0030] The purity of the ammonium carbonate is more than or equal to 99%;

[0031] 2) Use the "V" type mixer to mix the material weighed in 1) evenly, and the mixi...

Embodiment 2

[0040]1) Take silicon powder, silicon nitride powder and ammonium bicarbonate in proportion, wherein, the weight of silicon powder accounts for 35% of the total weight of silicon powder, silicon nitride powder and ammonium bicarbonate, and the weight of silicon nitride powder accounts for 55% of the total weight of silicon powder, silicon nitride powder and ammonium bicarbonate, and the weight of ammonium bicarbonate accounts for 10% of the total weight of silicon powder, silicon nitride powder and ammonium bicarbonate,

[0041] The purity of the silicon powder is ≥99.99%, the particle size is 0.1-25 μm, and the median particle size is 4.0 μm;

[0042] The silicon nitride powder has a purity ≥ 99.99%, an α-phase content of 90%, a particle size of 0.1-50 μm, and a median particle size of 5.8 μm;

[0043] The purity of the ammonium carbonate is more than or equal to 99%;

[0044] 2) Use the "V" type mixer to mix the material weighed in 1) evenly, and the mixing time is 15 minut...

Embodiment 3

[0053] 1) Weigh silicon powder, silicon nitride powder, ammonium carbonate and urea in proportion, wherein the weight of silicon powder accounts for 30% of the total weight of silicon powder, silicon nitride powder, ammonium carbonate and urea, and silicon nitride powder The weight accounts for 56% of the total weight of silicon powder, silicon nitride powder, ammonium carbonate and urea, the weight of ammonium carbonate accounts for 7% of the total weight of silicon powder, silicon nitride powder, ammonium carbonate and urea, and the weight of urea accounts for silicon powder, 7% of the total weight of silicon nitride powder, ammonium carbonate and urea,

[0054] The purity of the silicon powder is ≥99.99%, the particle size is 0.1-25 μm, and the median particle size is 3.5 μm;

[0055] The silicon nitride powder has a purity ≥ 99.99%, an α-phase content of 90%, a particle size of 0.1-50 μm, and a median particle size of 6.0 μm;

[0056] The purity of the ammonium carbonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com