A preparation method of micron-sized copper-germanium-zinc-tin-sulfur single crystal particles, single crystal particles and solar cells

A technology of solar cells and single crystal particles, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of small diffusion length, difficulty in growing large-size single crystals, difficulty in improving device conversion efficiency, etc., to achieve Effects of improving conversion efficiency, advanced optical characteristics, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

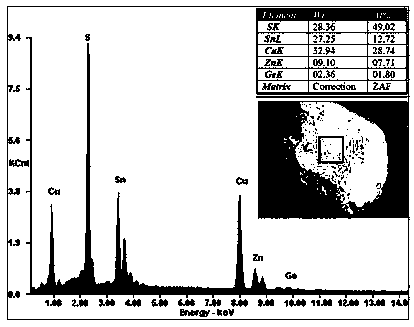

[0049] Weigh 18mmol CuS, 12mmol ZnS, 5mmol Ge, 5mmol SnS, 15mmol S and flux 120mmol CsCl as the reaction raw materials, mix and grind thoroughly to make it evenly mixed; put the mixed sample into a quartz bottle, and use a vacuum pump unit to evacuate Reach 10~10 2 Pa (can also be protected with an inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with the mixed sample in a common heating furnace and heat it from normal temperature to 800 Keep at ℃ for 72 hours, then cool down to 600℃, take out the quartz bottle and quickly cool it down to room temperature (put in water); finally take out the sample in the quartz bottle, wash it with ultrasonic water several times to remove the flux CsCl, and then put the sample in a drying oven at 80℃ After drying for 2 hours, micron-sized CGZTS single crystal particles with crystal luster on the surface were obtained, about 65 micr...

Embodiment 2

[0052] Weigh the reaction raw materials 22mmol Cu, 15mmol Zn, 5mmol Ge, 8mmol Sn, 50mmol S and flux 120mmol KI, mix and grind thoroughly to make it evenly mixed; put the mixed sample into a quartz bottle, and use a vacuum pump unit to evacuate Reach 10~10 2 Pa (can also be protected with an inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with the mixed sample in an ordinary heating furnace and heat it from normal temperature to 850 Keep the temperature at ℃ for 66 hours, then cool down to 600℃, take out the quartz bottle and quickly cool it down to room temperature (put it in water); finally take out the sample in the quartz bottle, wash it with ultrasonic water several times to remove the flux KI, and then put the sample in a drying oven at 80℃ After drying for 2 hours, micron-sized CGZTS single crystal particles with crystal luster on the surface were obtained, a...

Embodiment 3

[0055] Utilize the monocrystalline particle described in embodiment 1 to prepare solar cell, comprise the following steps:

[0056] 1. Prepare a layer of gum arabic film with a thickness of 15 μm on the substrate by pulling method;

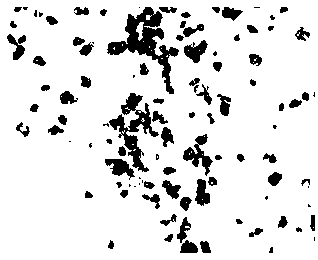

[0057] 2. After the gum arabic layer is cured, coat a layer of epoxy resin with a thickness of 80 μm on the gum arabic layer, and then weigh 20 g of CGZTS single crystal particles with a particle size of about 65 μm. When the epoxy resin layer is semi-cured, put The single crystal particles are uniformly embedded in the epoxy resin layer; the volume ratio of the single crystal particles to the epoxy resin is 1:1.7;

[0058] 3. After the epoxy resin is cured, use a grinder to grind off the 55 μm epoxy resin on the surface to expose the surface of the CGZTS single crystal particles;

[0059] 4. Clean the exposed surface of the CGZTS single crystal particles with HCl and deionized water, and dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com