A kind of peek denture tooth composite material and preparation method thereof

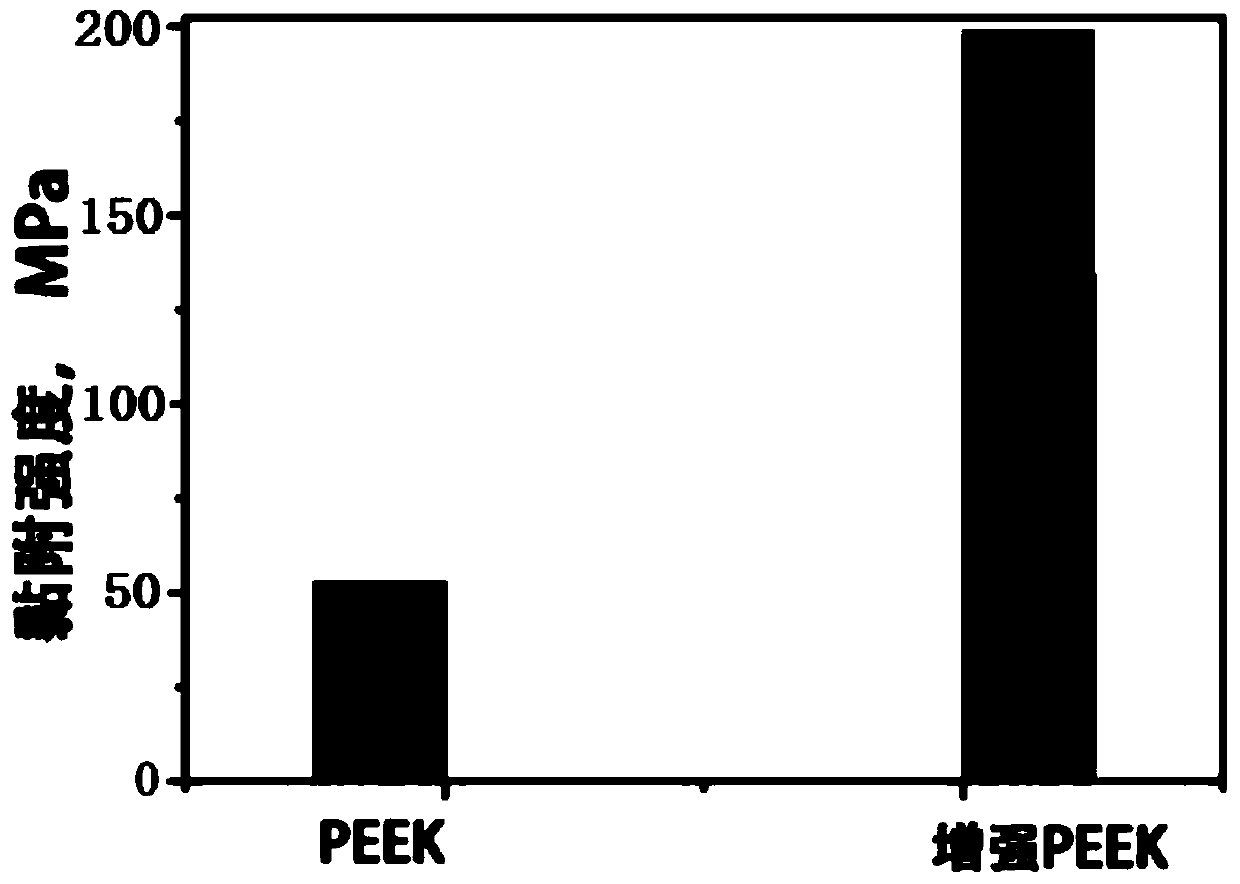

A composite material and denture technology, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of surface biological activity, physical and chemical properties of PEEK materials, pollution of PEEK materials, and high equipment requirements. The effect of bone potency and surface activity, strong abrasion resistance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] According to one aspect of the present invention, this embodiment provides a PEEK denture tooth composite material, and the PEEK denture tooth composite material is composed of the following raw materials in parts by weight: 150 parts of polyether ether ketone, 10 parts of nano calcium silicate, hydroxyl 8 parts of phosphate lime, 4 parts of short barium glass fiber, 15 parts of organic solvent, 8 parts of refined paraffin, 1 part of caking agent, 8 parts of binder, 2 parts of antibacterial agent, 6 parts of carbide and 15 parts of oxide. In this embodiment, the carbide is a mixture of tungsten carbide, titanium carbide, zirconium carbide, tantalum carbide, niobium carbide, hafnium carbide, chromium carbide and vanadium carbide, and the oxide is zirconia, titanium dioxide, silicon dioxide and the mixture of magnesium oxide; the component weight ratio of the mixture in the carbide described in this embodiment is: 0.4:2:1:0.3:0.7:0.6:0.5:0.5; the weight ratio of the mixtur...

Embodiment 2

[0034] According to one aspect of the present invention, this embodiment provides a kind of PEEK denture tooth composite material, and described PEEK denture tooth composite material is made up of the raw material of following parts by weight: polyetheretherketone 110 parts, nanometer calcium silicate 20 parts, hydroxyl 12 parts of phosphate lime, 8 parts of short barium glass fiber, 22 parts of organic solvent, 18 parts of refined paraffin, 4 parts of caking agent, 12 parts of binder, 6 parts of antibacterial agent, 10 parts of carbide and 11 parts of oxide. In this embodiment, the carbide is a mixture of titanium carbide, zirconium carbide, tantalum carbide, vanadium carbide and niobium carbide; the weight ratio of the mixture in the carbide is 4:2:1:2:1; the The oxide is a mixture of zirconia, titanium dioxide, silicon dioxide, tantalum pentoxide, magnesium oxide and calcium oxide, and the weight ratio of the mixture in the oxide is 3:4:1:0.4:0.6:2. Described organic solven...

Embodiment 3

[0042] According to one aspect of the present invention, this embodiment provides a PEEK denture tooth composite material, and the PEEK denture tooth composite material is composed of the following raw materials in parts by weight: 130 parts of polyether ether ketone, 16 parts of nano calcium silicate, hydroxyl 10 parts of apatite, 6 parts of short barium glass fiber, 18 parts of organic solvent, 15 parts of refined paraffin, 3 parts of caking agent, 10 parts of binder, 5 parts of antibacterial agent, 8 parts of carbide and 12 parts of oxide. In this embodiment, the carbide is a mixture of titanium carbide, zirconium carbide, chromium carbide, and vanadium carbide; the weight ratio of the mixture in the carbide is 3:4:2:1; the oxide is zirconia , titanium dioxide, magnesium oxide, calcium oxide, and tantalum pentoxide, and the weight ratio of the mixture in the oxide is 4:2:3:2:1. Described organic solvent is the mixture of tert-butyl hydroquinone and sulfolane, wherein, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com