Soil remediation fertilizer

A soil remediation and fertilizer technology, applied in the direction of organic fertilizers, inorganic fertilizers, ammonium salt fertilizers, etc., can solve the problems of destroying soil structure, soil fertility decline, and slow growth of super-accumulated plants, so as to repair heavy metal pollution in soil and repair soil Heavy metal, repair effect is remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

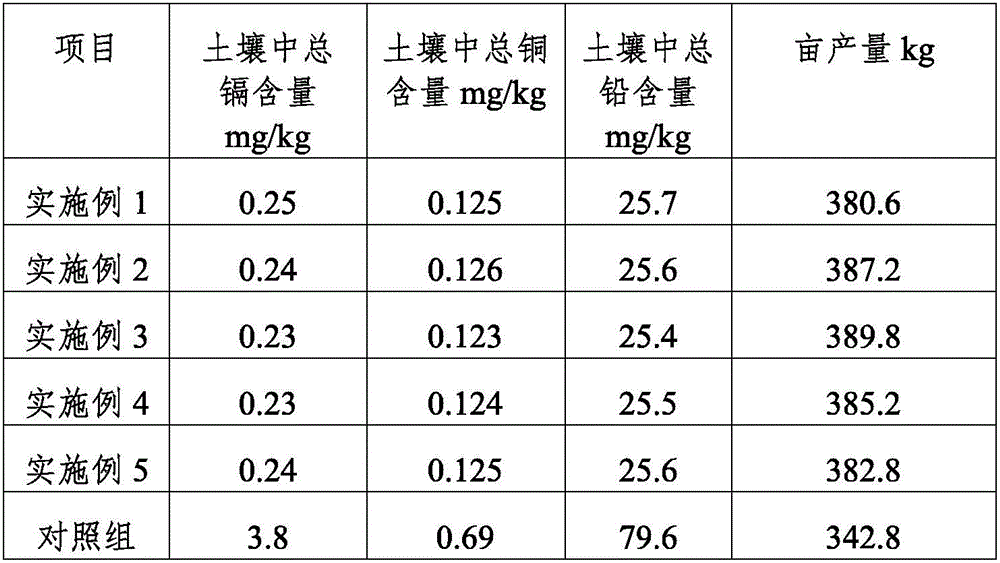

Examples

Embodiment 1

[0022] A soil remediation fertilizer, which is composed of the following raw materials in parts by weight: urea 30kg, sodium nitrate 25kg, ammonium sulfate 20kg, urea phosphate 25kg, calcium phosphate 10kg, potassium dihydrogen phosphate 20kg, potassium sulfate 15kg, clay 8kg, water chestnut Iron slag 10kg, limonite slag 10kg, bagasse 15kg, edible fungi slag 10kg, shell powder 12kg, modified red clay 25kg, modified kaolin 15kg, plant extract 15kg.

[0023] The modified laterite is to remove the impurities of the laterite, soak it in 25% salt water for 25 minutes, remove it, add oxalic acid, stir it with a magnetic stirrer for 2.5 hours at 85°C, and add 0.6 times the weight of the laterite. Sodium sulfonate, stirred for 35 minutes, removed, then calcined at 278°C for 45 minutes, soaked in 25% starch aqueous solution, ultrasonically treated at 200KHz for 10 minutes, dried, crushed through a 20-mesh sieve, and ready to serve .

[0024] Described modified kaolin is that kaolin an...

Embodiment 2

[0033] A soil remediation fertilizer, consisting of the following raw materials in parts by weight: urea 50kg, sodium nitrate 30kg, ammonium sulfate 25kg, urea phosphate 30kg, calcium phosphate 15kg, potassium dihydrogen phosphate 30kg, potassium sulfate 20kg, clay 12kg, water chestnut Iron slag 13kg, limonite slag 13kg, bagasse 20kg, edible fungus slag 18kg, shell powder 16kg, modified red clay 30kg, modified kaolin 20kg, plant extract 25kg.

[0034] The modified laterite is to remove the impurities of the laterite, soak it in 30% salt water for 30 minutes, remove it, add oxalic acid, stir with a magnetic stirrer for 3 hours at 90°C, and add dodecyl sulfonate 0.8 times the mass of the laterite. Sodium acid, stirred for 40 minutes, removed, calcined at 283°C for 55 minutes, soaked in 30% starch aqueous solution, ultrasonically treated at 230KHz for 13 minutes, dried, and crushed through a 40-mesh sieve.

[0035] The modified kaolin is to mix kaolin and 3.5mol / L sodium hydroxid...

Embodiment 3

[0044] It consists of the following raw materials in parts by weight: urea 40kg, sodium nitrate 28kg, ammonium sulfate 23kg, urea phosphate 28kg, calcium phosphate 13kg, potassium dihydrogen phosphate 25kg, potassium sulfate 18kg, clay 10kg, siderite slag 11kg, limonite 11kg of slag, 18kg of bagasse, 14kg of edible fungus slag, 14kg of shell powder, 28kg of modified red clay, 18kg of modified kaolin, and 20kg of plant extract.

[0045] The modified laterite is to remove the impurities of the laterite, soak it in 28% salt water for 28 minutes, remove it, add oxalic acid, stir with a magnetic stirrer for 2.8 hours at 88°C, and add 0.7 times the weight of the laterite. Sodium sulfonate, stirred for 38 minutes, removed, then calcined at 280°C for 50 minutes, soaked in starch aqueous solution with a concentration of 28%, ultrasonically treated at 220KHz for 11 minutes, dried, and crushed through a 30-mesh sieve. .

[0046] Described modified kaolin is that the sodium hydroxide of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com