Preparation method of highly-effective Cr (VI) absorption carbon-aluminum oxide composite material

A composite material and alumina technology, applied in the field of carbon-alumina composite material preparation, can solve problems such as low adsorption and removal rate, and achieve the effects of simple preparation process, low equipment requirements, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

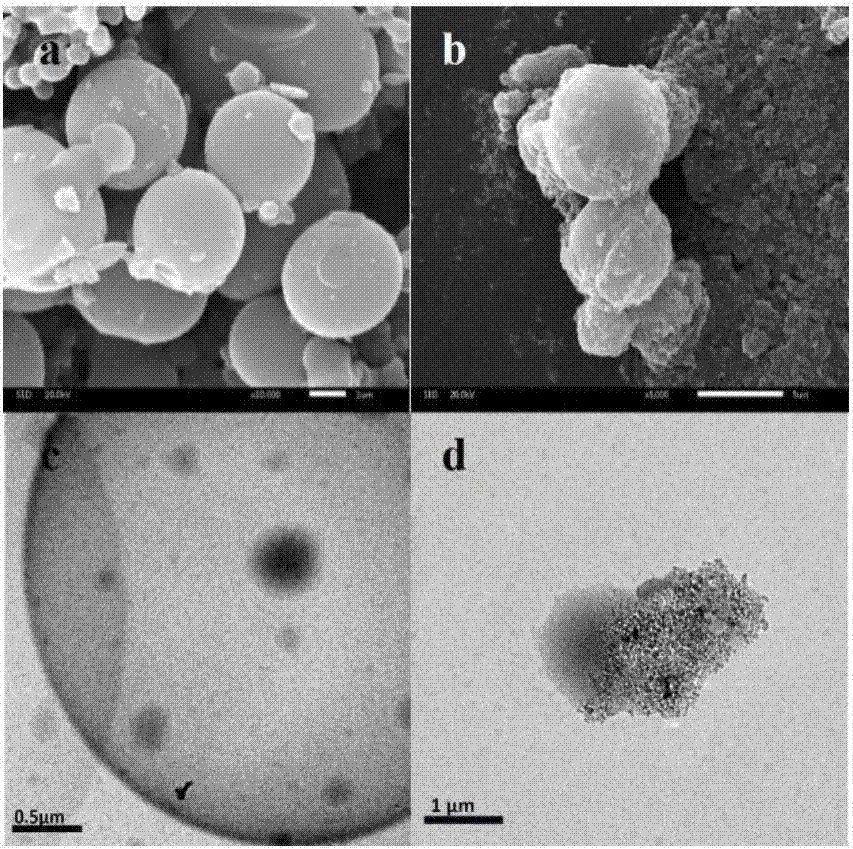

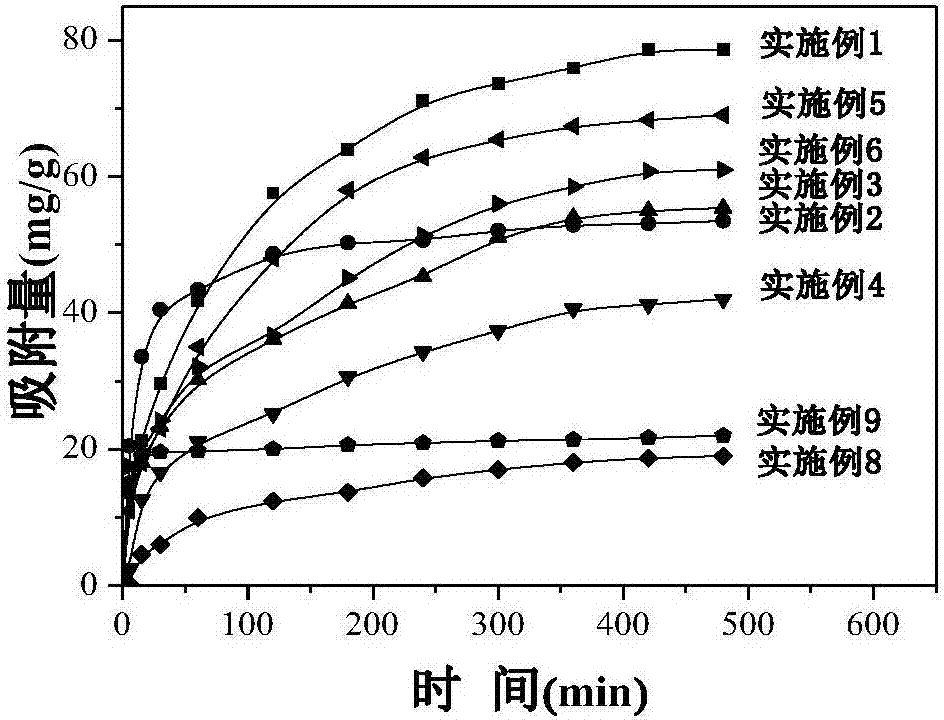

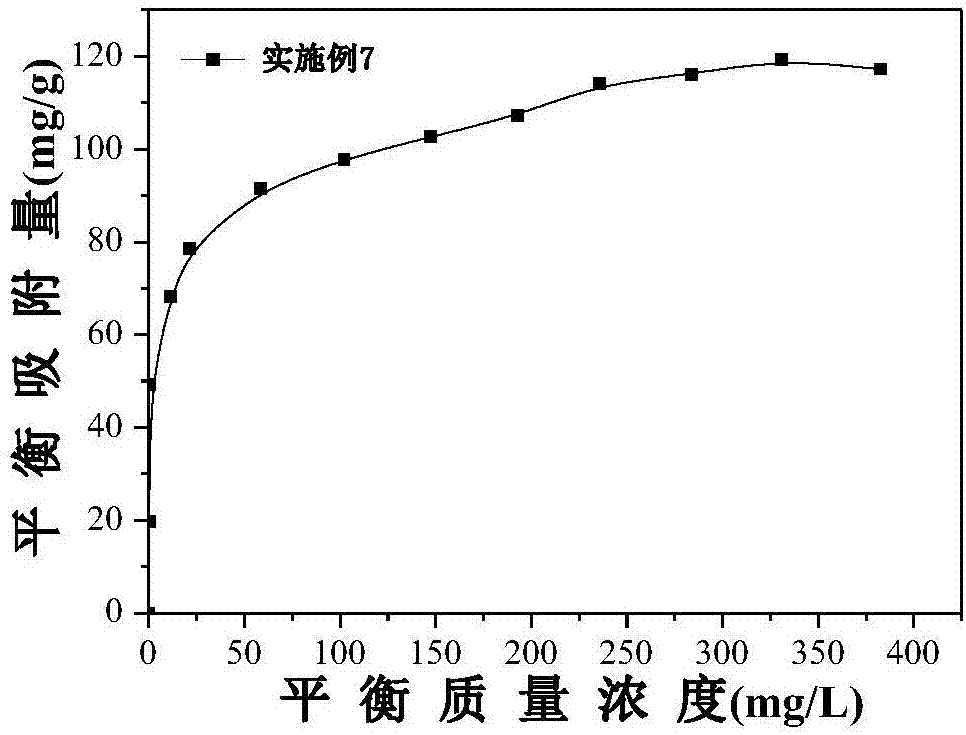

[0030] Slowly add 8.18g of aluminum isopropoxide into 72ml of deionized water, heat the oil bath to 90°C and hydrolyze for 1 hour, add 5ml of 2mol / L nitric acid solution dropwise and keep it at 90°C for condensing and refluxing for 12 hours, then cool to room temperature Pseudoboehmite sol was obtained; another 4g C 6 h 12 o 6 ·H 2Dissolve O in 40ml of deionized water, add 70mg of SDS and stir to form a mixed solution, mix the mixed solution with 10g of pseudo-boehmite sol, add 10ml of dehydrated ethanol with a mass fraction of 99.5%, ultrasonically for 10min, and mix well Place the suspension in a hydrothermal kettle, undergo hydrothermal reaction at 180°C for 12 hours, wash the obtained hydrothermal product alternately with water and absolute ethanol with a mass fraction of 99.5% for three times and centrifuge, and dry the centrifuged product at 80°C for 5 hours , dried product at 500°C, N 2 Roasting under the atmosphere for 4h, the obtained sample is a carbon-alumina co...

Embodiment 2

[0034] Slowly add 8.18g of aluminum isopropoxide into 72ml of deionized water, heat the oil bath to 90°C and hydrolyze for 1 hour, add 5ml of 2mol / L nitric acid solution dropwise and keep it at 90°C for condensing and refluxing for 12 hours, then cool to room temperature Pseudoboehmite sol was obtained; another 4g C 6 h 12 o 6 ·H 2 Dissolve O in 40ml of deionized water, add 70mg of SDS and stir to form a mixed solution, mix the mixed solution with 5g of pseudo-boehmite sol, add 10ml of absolute ethanol with a mass fraction of 99.5%, ultrasonicate for 10min, and mix well to suspend The solution was placed in a hydrothermal kettle, subjected to hydrothermal reaction at 170°C for 12 hours, the obtained hydrothermal product was alternately washed three times with water and absolute ethanol with a mass fraction of 99.5% and centrifuged, and the centrifuged product was generally dried at 90°C for 4 hours, Dry the product at 500°C, N 2 Calcined under atmosphere for 4h to obtain c...

Embodiment 3

[0037] Slowly add 8.18g of aluminum isopropoxide into 72ml of deionized water, heat the oil bath to 90°C and hydrolyze for 1 hour, add 5ml of 2mol / L nitric acid solution dropwise and keep it at 90°C for condensing and refluxing for 12 hours, then cool to room temperature Pseudoboehmite sol was obtained; another 4g C 6 h 12 o 6 ·H 2 Dissolve O in 40ml of deionized water, add 50mg of SDS and stir to form a mixed solution, mix the mixed solution with 10g of pseudoboehmite sol, add 5ml of dehydrated ethanol with a mass fraction of 99.5%, ultrasonicate for 10min, and mix the suspension Place in a hydrothermal kettle, undergo hydrothermal reaction at 160°C for 10 hours, wash the obtained hydrothermal product alternately with water and absolute ethanol with a mass fraction of 99.5% three times and centrifuge, dry the centrifuged product at 80°C for 5 hours, dry Product at 500°C, N 2 Calcined under atmosphere for 4h to obtain carbon-alumina composite material.

[0038] When absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com