One-step synthesized double perovskite potassium ion battery anode material and preparation method thereof

A double perovskite, battery negative electrode technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of slow potassium ion migration, material lattice transformation, and electrode material particle breakage, etc. Electron migration resistance, improving electron conductivity, and reducing the effect of grain boundary resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

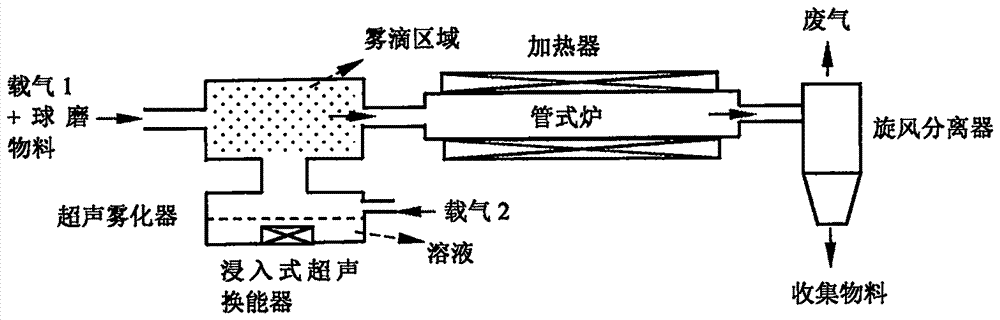

[0023] Embodiment 1: potassium nitrate, sodium nitrate, silver nitrate, zinc nitrate hexahydrate, zirconium nitrate pentahydrate, tantalum pentoxide are according to stoichiometric formula KNaTa 0.8 Zn 0.1 Ag 0.1 ZrO 6 Put into a ball mill, the mass ratio of the ball mill and the material is 20:1, and ball mill for 11 hours at a speed of 200 rpm. The ball-milled material is fed into such as figure 1 In the synthesizer shown, the flow velocity of the air is 0.5m 3 min -1 ; The synthesis device consists of four parts: an ultrasonic atomizer, a droplet area, a tube furnace and a cyclone separator; at the same time, start the ultrasonic atomizer and immerse in 1.0mol L -1 An immersion ultrasonic transducer with a power of 250W in potassium nitrate aqueous solution produces a large number of mist droplets and the flow rate is 0.5L min -1 The mixed gas of oxygen and argon with a volume ratio of 20:80 is carried from below to the droplet area; the air carries the ball-milled ma...

Embodiment 2

[0024] Embodiment 2: potassium nitrate, sodium nitrate, silver nitrate, zinc nitrate hexahydrate, zirconium nitrate pentahydrate, tantalum pentoxide are according to stoichiometric formula KNaTa 0.8 Zn 0.1 Ag 0.1 ZrO 6 Put into the ball mill, the mass ratio of the ball mill and the material is 20:1, and ball mill for 19 hours at a speed of 400 rev / min. The ball-milled material is fed into such as figure 1 In the synthesizer shown, the air velocity is 3.5m 3 min -1 ; The synthesis device consists of four parts: ultrasonic atomizer, drop zone, tube furnace and cyclone separator; at the same time, start the ultrasonic atomizer and immerse in 1.5mol L -1 An immersed ultrasonic transducer with a power of 250W in potassium nitrate aqueous solution produces a large number of mist droplets and the flow rate is 3.5L min -1 The mixed gas of oxygen and argon with a volume ratio of 20:80 is carried from below to the droplet area; the air carries the ball-milled material through the ...

Embodiment 3

[0025] Embodiment 3: potassium nitrate, sodium nitrate, silver nitrate, zinc nitrate hexahydrate, zirconium nitrate pentahydrate, tantalum pentoxide are according to stoichiometric formula KNaTa 0.8 Zn 0.1 Ag 0.1 ZrO 6 Put into ball mill, the mass ratio of ball mill and material is 20: 1, with the speed ball mill of 300 rev / mins 15 hours. The material after ball milling is sent into such as figure 1 In the synthetic device shown, the flow rate of nitrogen is 3.0m 3 min -1 ; The synthesis device consists of four parts: an ultrasonic atomizer, a droplet area, a tube furnace and a cyclone separator; at the same time, start the ultrasonic atomizer and immerse in 1.2mol L -1 An immersion ultrasonic transducer with a power of 250W in potassium nitrate aqueous solution produces a large number of droplets and the flow rate is 2.5L min -1 The mixed gas of oxygen and argon with a volume ratio of 20:80 is carried from below to the droplet area; nitrogen carries the ball-milled mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com