Medium temperature catalytic denitration and heat storage composite ceramic material

A technology of composite ceramics and ceramic materials, which is applied in the field of composite ceramic materials, can solve the problems of increased electricity cost of induced draft fans, narrow active temperature window, and no heat storage function, so as to improve energy utilization efficiency, improve anti-sintering ability, Wide effect of denitrification activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

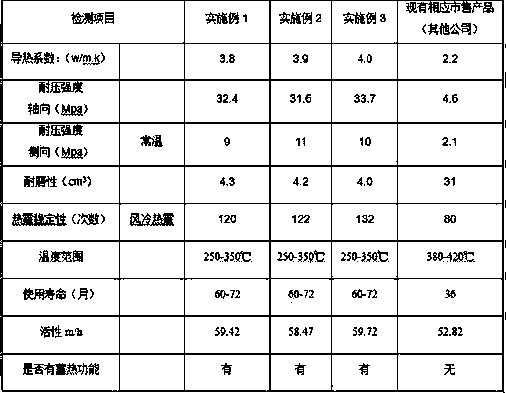

Examples

Embodiment 1

[0028] A medium-temperature catalytic denitrification heat storage composite ceramic material mainly consists of the following components: 20 parts of spodumene, 80 parts of mullite, 5 parts of silicon carbide, 8 parts of alumina micropowder, 10 parts of calcium carbonate whiskers, cellulose fiber 3 parts, 4 parts of carbon fiber, 7 parts of chlorinated polyethylene, 1 part of methyl methacrylate-butadiene-styrene terpolymer, 6 parts of hydroxypropyl methylcellulose, 3 parts of phthalate 1 part, 3 parts of monoethanolamine and 1 part of stearic acid are prepared by kneading mud, stale, extruded, dried and calcined, impregnated with catalytic slurry, dried and calcined again.

[0029] The catalytic slurry is mainly composed of the following components: 5 parts of alumina, 10 parts of ferric nitrate, 15 parts of manganese nitrate, 5 parts of mullite, 5 parts of ammonium dihydrogen phosphate, 2 parts of polydimethylsiloxane, 10 parts of aluminum stearate, 5 parts of yttrium nitra...

Embodiment 2

[0043] A medium-temperature catalytic denitrification heat storage composite ceramic material mainly consists of the following components: 22 parts of spodumene, 75 parts of mullite, 6 parts of silicon carbide, 7 parts of alumina micropowder, 13 parts of calcium carbonate whiskers, cellulose fiber 2 parts, 4 parts of carbon fiber, 9 parts of chlorinated polyethylene, 2 parts of methyl methacrylate-butadiene-styrene terpolymer, 5 parts of hydroxypropyl methylcellulose, 3 parts of phthalate 2 parts, 2 parts of monoethanolamine and 2 parts of stearic acid are prepared by kneading mud, stale, extruded, dried and calcined, impregnated with catalytic slurry, dried and calcined again.

[0044] The catalytic slurry is mainly composed of the following components: 6 parts of alumina, 8 parts of iron nitrate, 10 parts of manganese nitrate, 9 parts of mullite, 8 parts of ammonium dihydrogen phosphate, 1.3 parts of polydimethylsiloxane, 7 parts of aluminum stearate, 4 parts of yttrium nitr...

Embodiment 3

[0058] A medium-temperature catalytic denitrification heat storage composite ceramic material mainly consists of the following components: 23 parts of spodumene, 70 parts of mullite, 7 parts of silicon carbide, 5 parts of alumina micropowder, 15 parts of calcium carbonate whiskers, cellulose fiber 2 parts, 5 parts of carbon fiber, 10 parts of chlorinated polyethylene, 2 parts of methyl methacrylate-butadiene-styrene terpolymer, 3 parts of hydroxypropyl methylcellulose, 2 parts of phthalate 2 parts, 2 parts of monoethanolamine and 3 parts of stearic acid are prepared by kneading mud, stale, extruded, dried and calcined, impregnated with catalytic slurry, dried and calcined again.

[0059] The catalytic slurry is mainly composed of the following components: 8 parts of alumina, 5 parts of iron nitrate, 5 parts of manganese nitrate, 10 parts of mullite, 10 parts of ammonium dihydrogen phosphate, 0.5 parts of polydimethylsiloxane, 6 parts of aluminum stearate, 3 parts of yttrium ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com