Biomass granular carbon-based fertilizer and preparation method thereof

A biomass granular carbon and fertilizer technology, which is applied in the direction of fertilizers made of biological waste, biofuels, calcium fertilizers, etc., can solve the problem of the inability to inhibit the enrichment of pathogenic microorganisms and harmful substances in carbon powder, and the unresolved micropores of biomass carbon. , Defective lesions of corn plants and other problems, to achieve the effect of increasing added value, increasing added value of biomass, and improving the ability to resist adverse environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

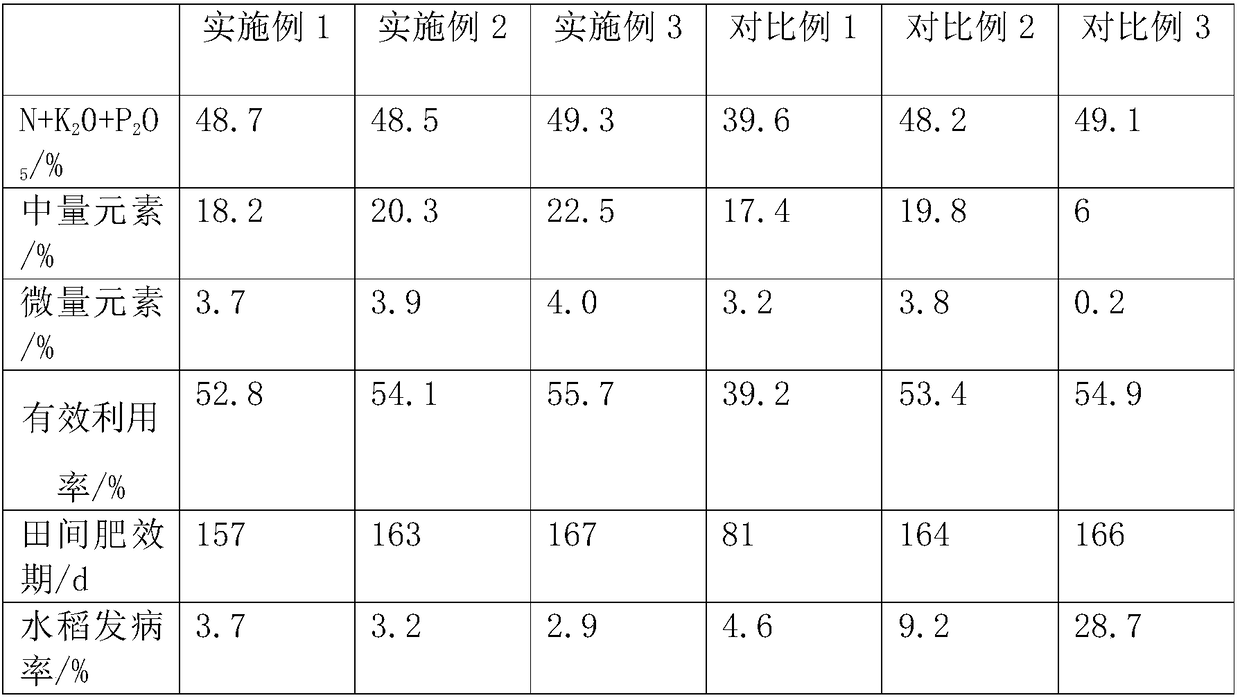

Examples

Embodiment 1

[0027] A biomass granular carbon-based fertilizer, comprising the following components in parts by weight: 20 parts of manure residue, 35 parts of straw mixture, 12 parts of castor meal, 15 parts of furfural residue, 7 parts of sulfonated lignin-vinyl acetate, and arbuscular 6 parts of mycorrhizae, 21 parts of medium elements, and 4 parts of trace elements.

[0028] In the present embodiment, the preparation method of above-mentioned a kind of biomass granular carbon-based fertilizer comprises the following steps:

[0029] Step 1: Mix corn stalks and wheat stalks to obtain a straw mixture, crush it to 60 mesh, dry it until the moisture content is lower than 20%, and heat it up to 500°C at 8°C / min under 60KPa nitrogen conditions, carbonize and pyrolyze 6h, and separate the biomass gas whose main components are methane, hydrogen and carbon monoxide, which can be applied to clean energy and produce straw charcoal;

[0030] Step 2: Mix sheep manure, cow manure, and chicken manure...

Embodiment 2

[0034] 25 parts of dung, 38 parts of straw mixture, 14 parts of castor meal, 19 parts of furfural residue, 8 parts of sulfonated lignin-vinyl acetate, 7 parts of arbuscular mycorrhiza, 23 parts of medium elements, and 4.5 parts of trace elements.

[0035] Preparation method is with embodiment 1, difference is:

[0036] Step 1: The straw mixture includes corn straw, wheat straw, and cotton straw, the crushing fineness is 70 mesh, the nitrogen pressure is 70KPa, the heating rate is 10°C / min, and the maximum temperature is 550°C;

[0037] Step 2: The weight ratio of the components of dung is 1:0.7:1.4, the liquefaction temperature and days are 25-30°C, 2-3d, and the biogas fermentation temperature and days are 45°C, 11d;

[0038] Step 3: The concentration of potassium hydroxide is 0.15mol / L, the steam expansion pressure and temperature are 0.6-1.8MPa, 138°C, and the total expansion time is 13min;

[0039] Step 4: The homogenization speed is 8000r / min.

Embodiment 3

[0041] 30 parts of dung, 40 parts of straw mixture, 16 parts of castor meal, 23 parts of furfural residue, 9 parts of sulfonated lignin-vinyl acetate, 8 parts of arbuscular mycorrhiza, 25 parts of medium elements, and 5 parts of trace elements.

[0042] Preparation method is with embodiment 1, difference is:

[0043] Step 1: The straw mixture includes corn straw, wheat straw, cotton straw, and peanut straw, the crushing fineness is 80 mesh, the nitrogen pressure is 80KPa, the heating rate is 12°C / min, and the maximum temperature is 600°C;

[0044] Step 2: The weight ratio of the components of dung is 1:0.8:1.6, the liquefaction temperature and days are 30°C and 3 days, and the biogas fermentation temperature and days are 55°C and 12 days;

[0045] Step 3: The concentration of potassium hydroxide is 0.2mol / L, the steam expansion pressure and temperature are 1.8MPa, 140°C, and the total expansion time is 15min;

[0046] Step 4: The homogenization speed is 10000r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com