Self-assembly heavy metal adsorbent as well as preparation method and application thereof

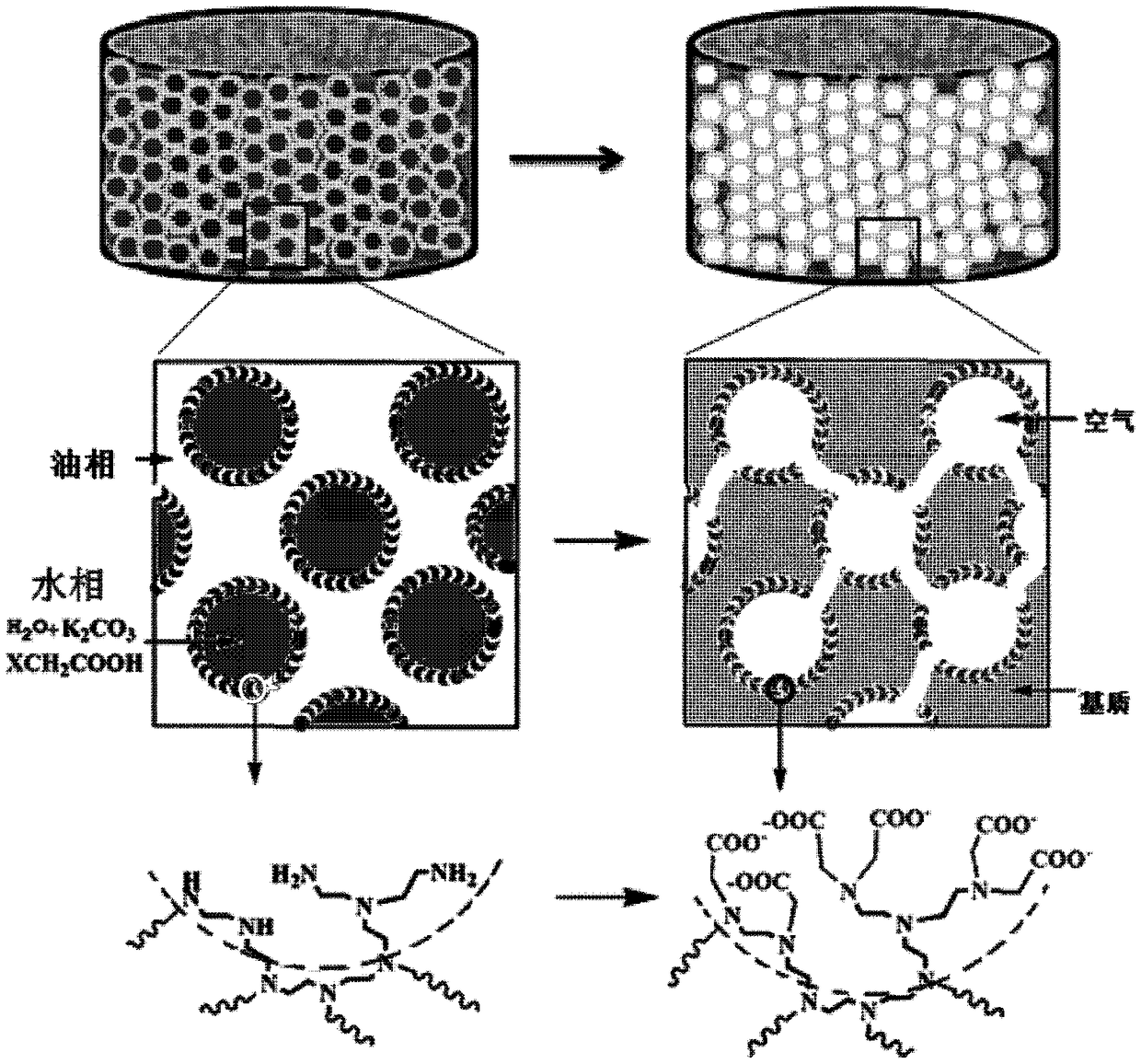

An adsorbent and heavy metal technology, which is applied in the field of self-assembled heavy metal adsorbent and its preparation, can solve the problems of low processing efficiency, harsh operating conditions, low-density slurry, etc., and achieve the effect of high density and surface coverage and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Synthesis of dendritic amphiphiles. Weigh hyperbranched polyethyleneimine, referred to as PEI (M n =10000, product of Sigma Company, vacuum-dried at 60°C in advance to remove possible absorbed carbon dioxide) (2.88g, 0.067mol equivalent of NH) was dissolved in chloroform (30mL), added hexadecyl glycidyl ether, referred to as C16 (7.04 g, 0.0235mol), stirred at room temperature for 3 days, chloroform was removed by rotary evaporation, or precipitated with ethanol and dried to obtain a white solid (9.92g, 100%), named PEI@C16 0.35 (0.35 means that 35% of amino hydrogens are alkylated, the same below). The amphiphile is apparently soluble in non-polar or weakly polar solvents such as chloroform, toluene, methylene chloride, carbon tetrachloride, cyclohexane, n-hexane, ether, and insoluble in ethanol, N,N-dimethyl Non-polar solvents such as methylformamide, dimethylsulfoxide, water, etc. The binding energy and mole fraction of carbon, nitrogen and oxygen measured by ...

Embodiment 2

[0058] (1) The dendritic amphiphile is the same as in Example 1, which is PEI@C16 0.35 .

[0059] (2) Synthesis of bulk adsorbent

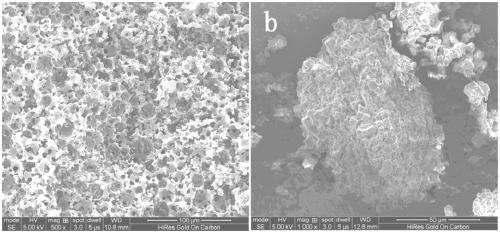

[0060] Styrene (1.8g), divinylbenzene (0.36g), azobisisobutylcyanide (12mg), PEI@C16 0.35 (0.24 g, ~1.05 mmol NH) were mixed to form an oil phase. Water (10 mL), chloroacetic acid (0.17 g, 1.8 mmol), potassium carbonate (0.5 g, 3.6 mmol) were mixed to form an aqueous phase. Add the water phase to the vigorously stirred oil phase, drop it within 20 minutes, and continue stirring for 15 minutes to form a creamy viscous emulsion. Transfer the paste into a polyethylene plastic cup, and heat it at 70-80°C for 24 hours to obtain a solid block. Washed with water and ethanol in turn, dried, named PolyHIPE-2, its partial scanning electron microscope picture is as follows figure 2 Shown in a.

[0061] Mercury porosimetry (generally can only measure large pores) to measure the specific surface is 46m 2 / g, the pore size is mainly distributed in the r...

Embodiment 3

[0068] Same as Example 2, except that bromoacetic acid was used instead of chloroacetic acid when the porous block was synthesized to obtain the block adsorbent PolyHIPE-3, similar to Table 2 for metal adsorption, the results are shown in Table 3.

[0069] Table 3 Adsorption of several metal ions by the adsorbent PolyHIPE-3 (unit: ppm), pH=6.0-7.0

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com