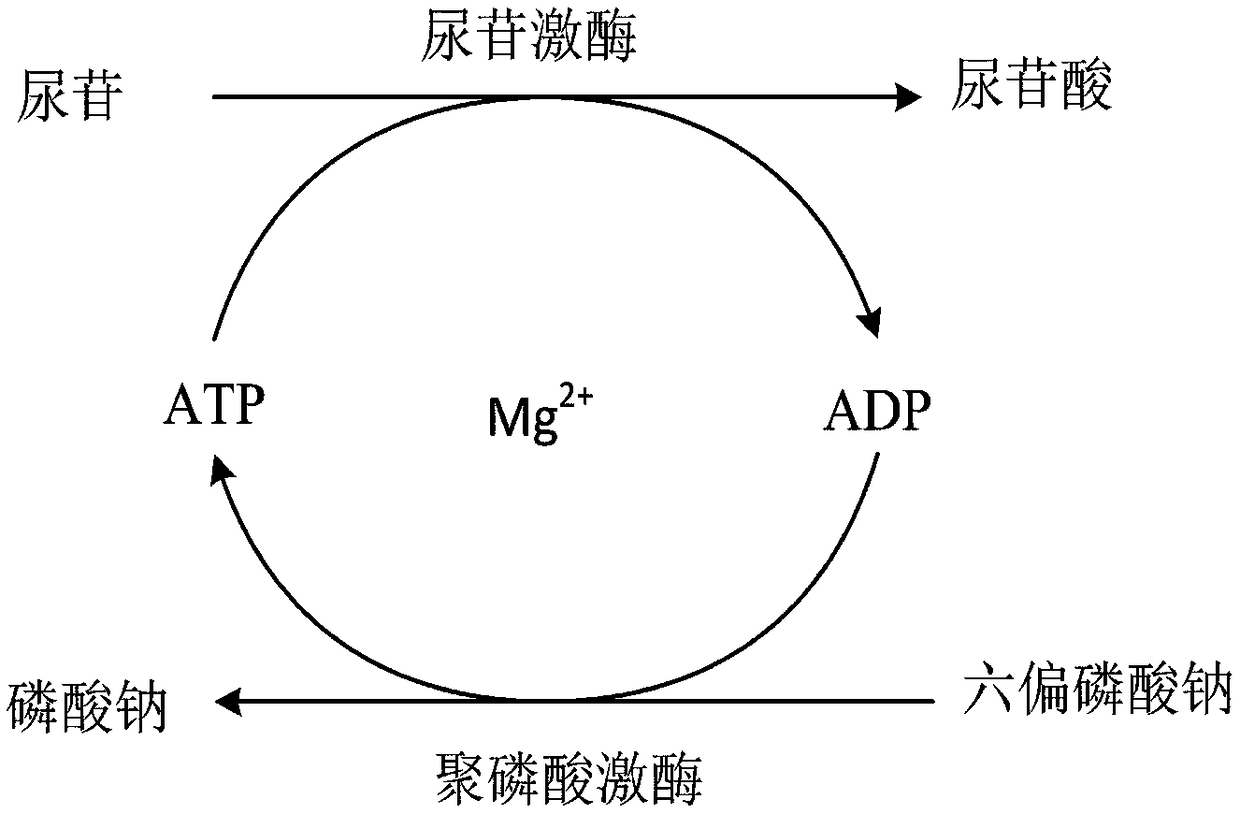

Enzyme preparation for preparing uridylic acid and method for preparing uridylic acid through enzyme catalysis

A technology of uridylic acid enzyme and uridine acid, which is applied in the field of compound biotechnology production, can solve the problems of short conversion cycle, high price, high regeneration cost, etc., and achieve the effects of easy cultivation, reduced production cost and superior yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preferably, the preparation method of above-mentioned uridine acid, concrete steps are as follows:

[0036] (1) Heterologously express the gene encoding uridine kinase in E. coli E. coli BL21 (ACCC11171), and construct a strain E. coli UDK with uridine kinase activity;

[0037] (2) Heterologous expression of polyphosphokinase coding gene in Escherichia coli E.coli BL21 (ACCC11171) to construct a strain E.coli PPK with polyphosphokinase activity;

[0038] (3) Culture the recombinant strains E.coli UDK and E.coli PPK constructed above in culture medium to produce uridine kinase and polyphosphate kinase with high enzymatic activity;

[0039] (4) Breaking the Escherichia coli cells (E.coli UDK and E.coli PPK cells) with uridine kinase and polyphosphokinase activities obtained by culturing in step (3) to obtain a crude enzyme solution;

[0040] (5) Mix the crude enzyme liquid obtained in step (4) with 50-150mM uridine solution or uridine fermentation broth, 50-150mM sodium ...

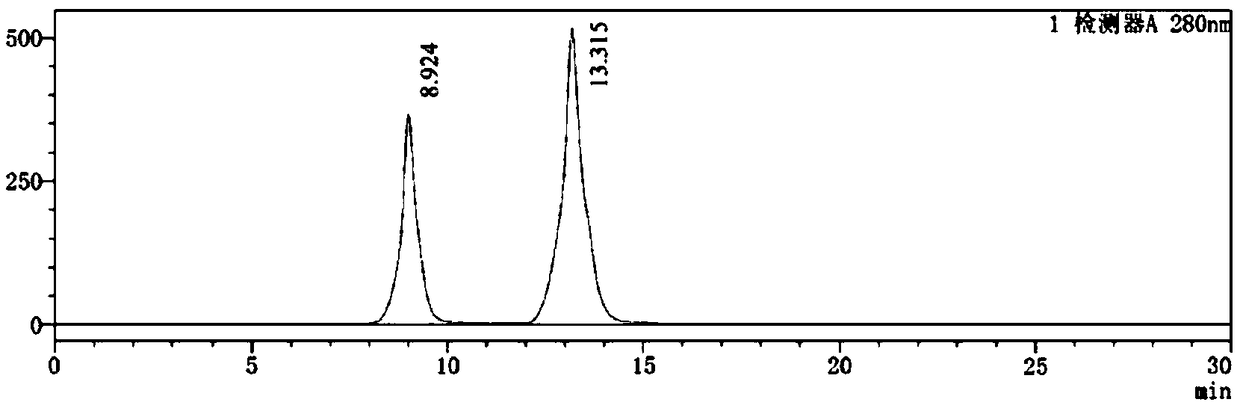

Embodiment 1

[0049] Construction of strain E.coli UDK with uridine kinase activity

[0050] ①According to the nucleotide sequence of the uridine kinase encoding gene udk 1 of Thermus thermophiles (ATCC27634) on Genbank, design a point mutation on the 93rd amino acid sequence to mutate the tyrosine residue to histidine acid residues, and codon-optimize them with common codon optimization methods in Escherichia coli, and send the optimized sequence plus the enzyme cutting sites BamH I and EcoR I (see Appendix ) to Jinweizhi Company for synthesis .

[0051] ②According to the nucleotide sequence of the uridine kinase sequence encoding gene udk2 of Bacillus sp. (NCBI: txid1960589) on Genbank, the codon optimization method was used to optimize the codon in Escherichia coli, and the optimized sequence Plus restriction sites BamH I and EcoR I (see appendix ) were sent to Jinweizhi Company for synthesis.

[0052] ③ Use Takara restriction endonuclease BamH I and EcoR I to double digest the target ...

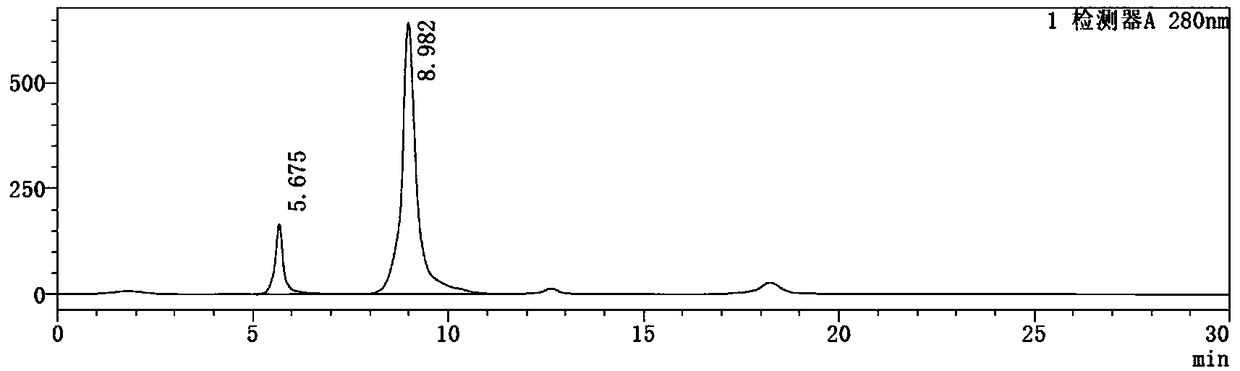

Embodiment 2

[0056] Construction of strain E.coli PPK with polyphosphokinase activity

[0057] ①Using PCR technology to use Rhodobacter sphaeroides (ATCC17023) genome as a template, design a pair of gene amplification primers (see appendix 7>) to amplify and obtain the target gene fragment. The pair of primers respectively comprise enzyme cutting sites EcoR I and Hind III.

[0058] ② Use PCR technology to design a pair of gene amplification primers ( See Appendix ) to amplify and obtain target gene fragments. The pair of primers respectively comprise enzyme cutting sites EcoR I and HindIII.

[0059] ③Use Takara restriction endonuclease EcoR I and Hind III to obtain the target fragment and pET-28a vector plasmid (see Appendix ) in steps ① and ② to obtain the target gene with the same cohesive end and linearize it Plasmid fragments.

[0060] ④ Ligate the gene fragments obtained in step ③ using Takara T4 DNA ligase to obtain two recombinant expression vectors pET-28a-ppk 1 and pET-28a-pp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com