Enzyme amino acid nano-selenium micro-fertilizer for degrading grain pesticide residues, preparation method and application

A technology of amino acid and nano-selenium, applied in the field of plant nutrition, can solve the problems of inability to supplement SOD and degrade drug residues, and achieve the effect of reducing pesticide residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

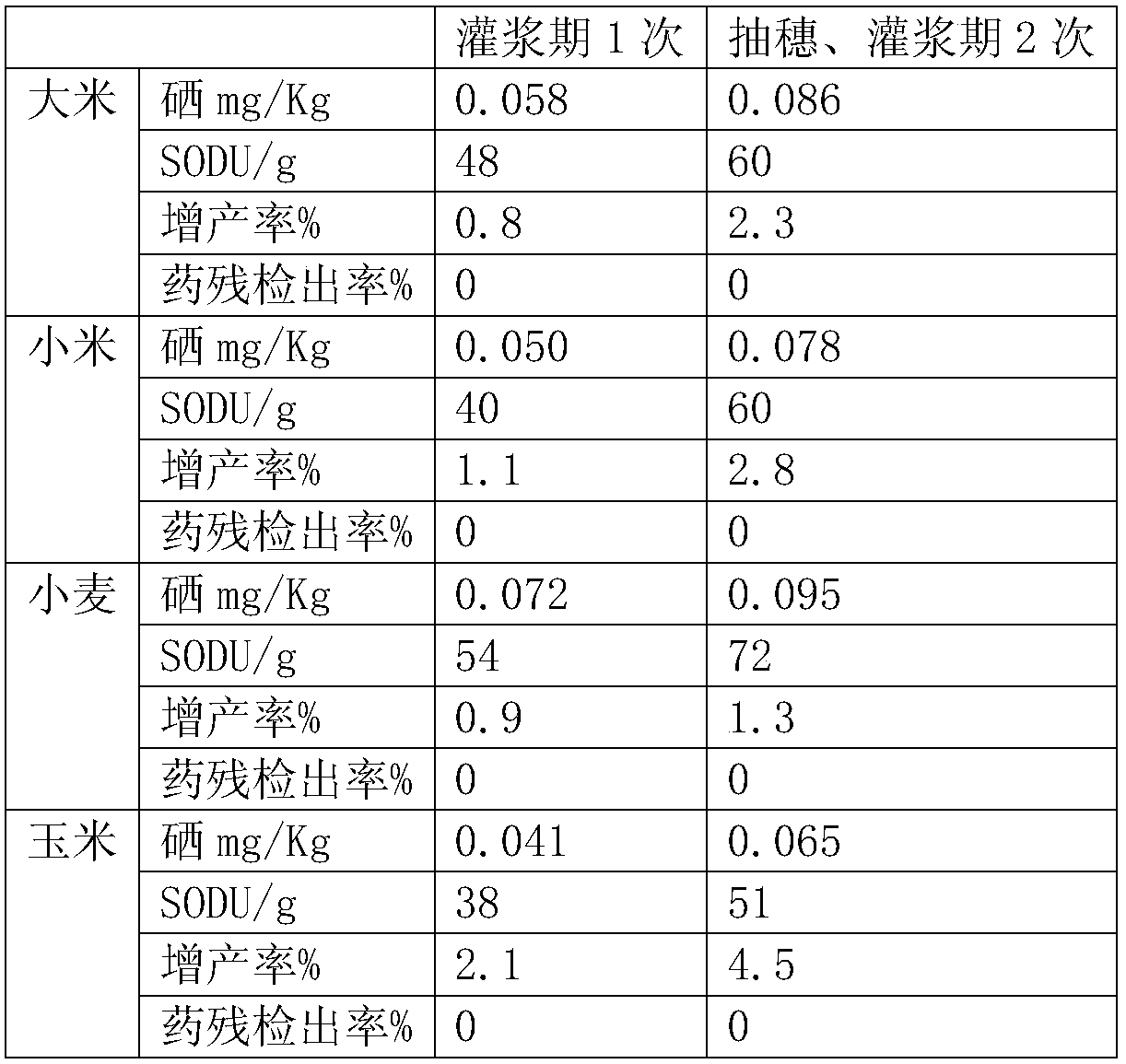

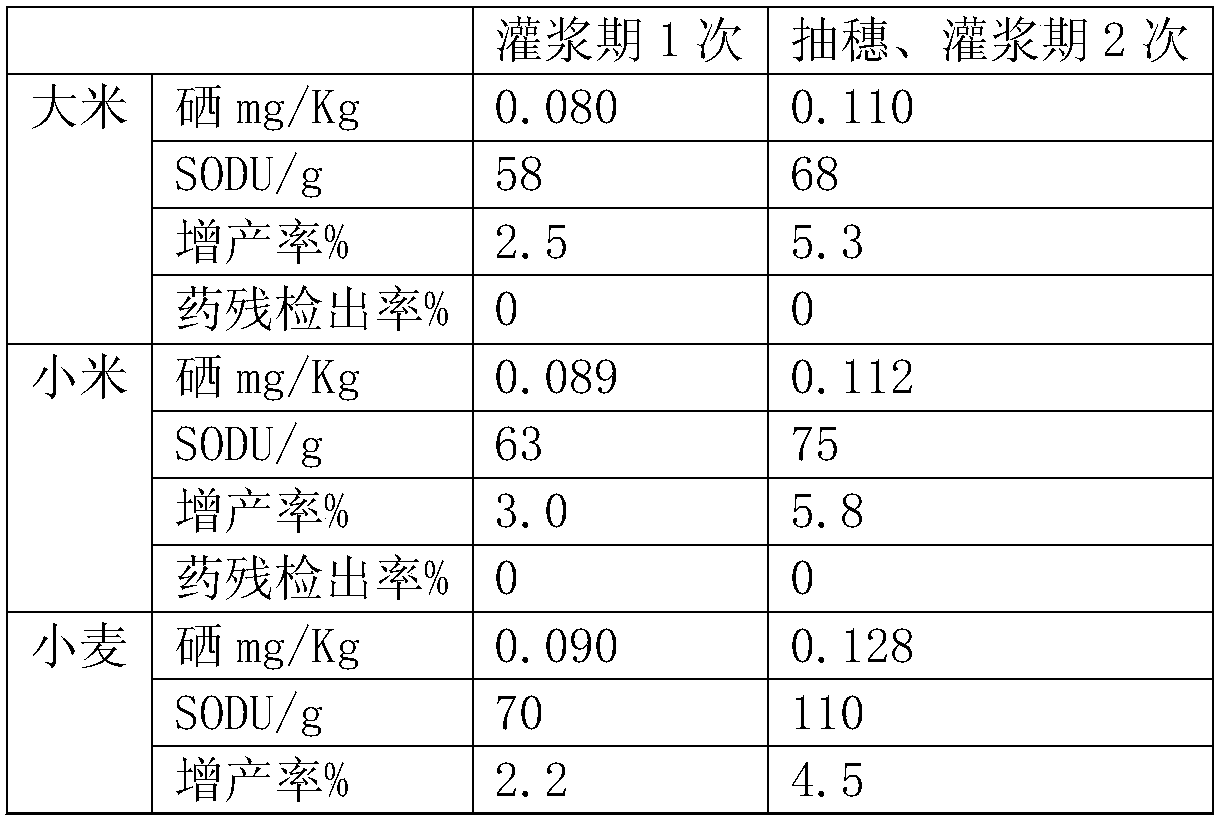

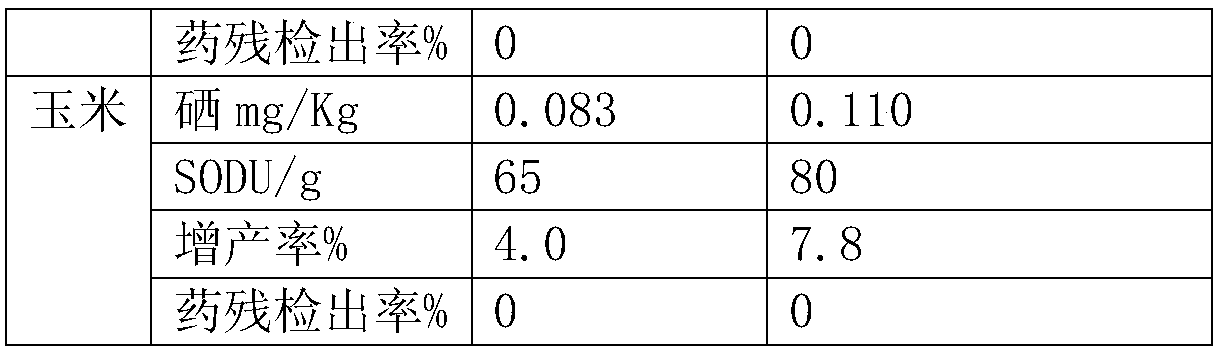

Examples

Embodiment 1

[0041]Take 15g of sodium selenobisulfate, 500g of water-soluble fertilizer containing amino acid trace elements, 120g of electrolyte pH buffer, including 45g of potassium dihydrogen phosphate, 45g of dipotassium hydrogen phosphate, 30g of calcium chloride, 20g of magnesium sulfate; 50g of amino acid raw powder, Organic base material 230g, including peptone 10g, brown sugar 200g, glucose 20g, selenium-enriched SOD nutrition material 255g, including selenium-enriched SOD honey 50g, selenium-enriched SOD blueberry juice puree 100g, selenium-enriched SOD miscellaneous grain enzyme 100g; α-starch, Protein, xylan mixed enzyme 5g; probiotics 255g, including 250g of microselenium, 5g of solid microselenium; growth regulator 10g, including 5g of alginic acid polysaccharide, 5g of biochemical potassium fulvic acid; EDTA disodium chelation Stabilizer 50g; purified water 48495g. Put it in a clean plastic bucket, stir and dissolve until it turns slightly brown, and the pH is 6.2-7.2, cover...

Embodiment 2

[0050] Take 30g of sodium bisulfate selenide, 800g of amino acid trace element water-soluble fertilizer, 180g of electrolyte pH buffer solution, including 60g of potassium dihydrogen phosphate, 60g of dipotassium hydrogen phosphate, 35g of calcium chloride, 25g of magnesium sulfate; 80g of amino acid raw powder, organic matter Base material 305g, selenium-enriched SOD nutritional material 380g, that is, selenium-enriched SOD honey 75g, selenium-enriched SOD blueberry juice puree 150g, selenium-enriched SOD miscellaneous grain enzyme 150g; α-starch, protein, xylan mixed enzyme 5g, probiotics 510g , including 500g of Yiwei bacteria, 10g of solid Yiwei; 20g of growth regulators, including 10g of alginic acid polysaccharide, 10g of biochemical potassium fulvic acid; 80g of disodium EDTA chelating stabilizer, and 47615g of purified water. Preparation operation is the same as example 1. The nano-selenium particle size is 20-40nm, the selenium content of the nano-selenium is 263mg / kg...

Embodiment 3

[0059] Enzyme amino acid nano-selenium micro-fertilizer was diluted 15 times, sprayed twice at the pod setting stage and 15 days before harvesting of soybeans, mung beans and red beans respectively, the selenium content of selenium-enriched SOD soybeans, mung beans and red beans can be seen from Table 5 4.4 times, 4.9 times and 4.8 times of the control value respectively, SOD is 3.5 times, 3.6 times and 3.2 times of the control value respectively, and the yield increase rate is 8.5%, 5.8% and 6.3% respectively; The selenium content, SOD and yield increase rate of the 200Kg selenium-enriched organic fertilizer as the base fertilizer are significantly higher than those of only two leaf sprays. The selenium content of selenium-enriched SOD soybeans, mung beans and red beans are 6.2 times, 7.0 times and 6.7 times the control value, respectively. SOD is 5.5 times, 5.7 times and 5.0 times of the control value respectively, and the yield increase rate is 14.4%, 9.0% and 10.6% respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com