Mulberry enzymatic hydrolysate and prepared mulberry rice vinegar

A mulberry enzymatic hydrolysate, mulberry rice technology, applied in the preparation of vinegar, microorganism-based methods, biochemical equipment and methods, etc., can solve problems such as poor effect, and achieve improved taste and flavor, rich nutrition, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 Aspergillus mularis enzymatic hydrolyzate

[0026] Described Aspergillus mulberry enzymolysis solution, its preparation method is as follows:

[0027] 1) destemming fresh mulberries, crushing and beating to make slurry;

[0028] 2) inserting the Aspergillus FJ036 strain into the sterilized mulberry pulp, and carrying out fermentation culture; after the fermentation, centrifuging to obtain the Aspergillus FJ036 enzyme fermentation liquid;

[0029] 3) Add 0.5 g / kg pectinase (50,000 U / g) to the sterilized mulberry fruit pulp in a 50°C water bath for 1.5 hours, cool down to 30°C, insert Aspergillus FJ036 enzyme fermentation broth, and perform enzymatic treatment; After the enzymatic hydrolysis, the Aspergillus FJ036 enzymatic hydrolyzate was prepared.

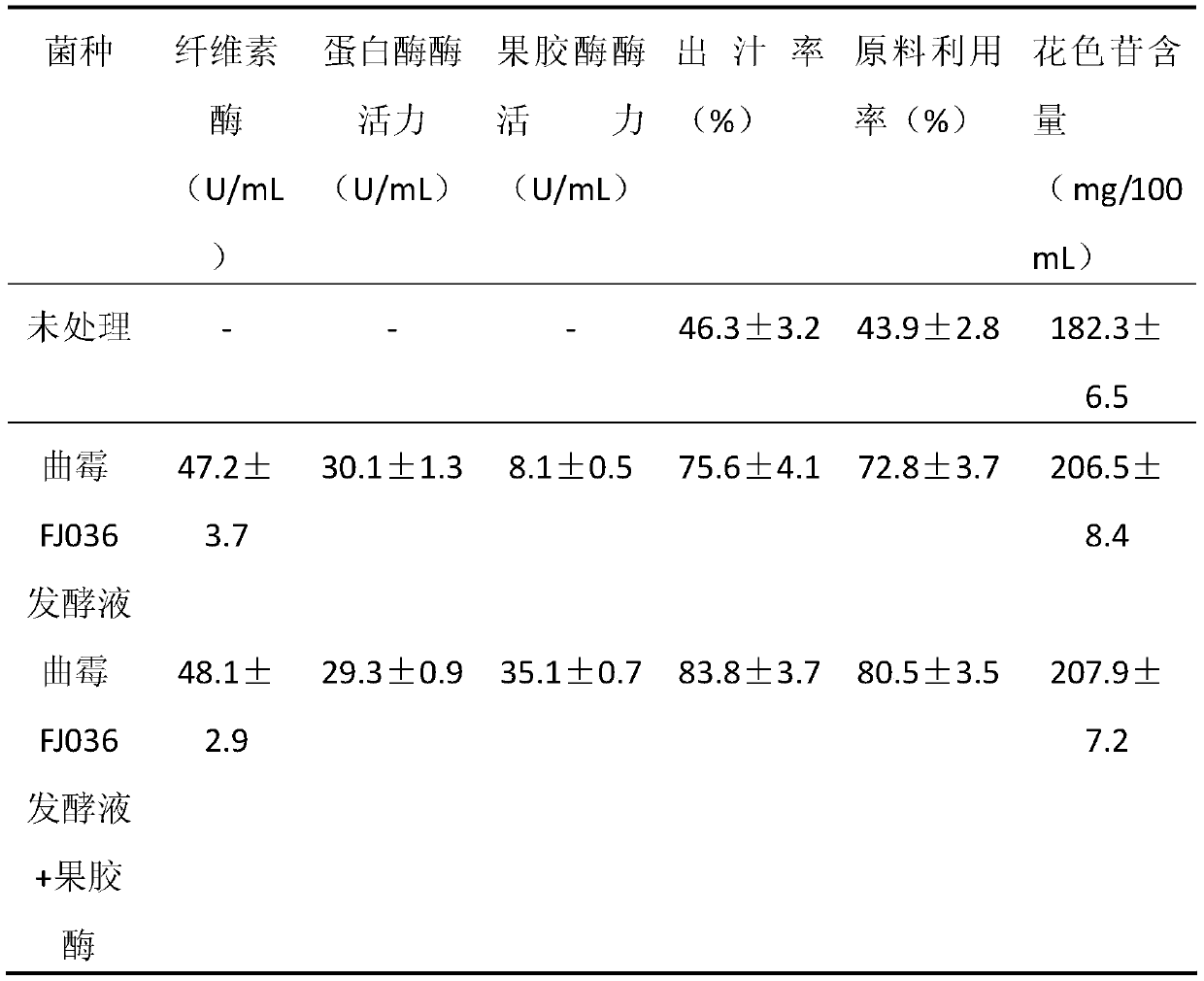

[0030] Table 1: Comparison table of enzymatic hydrolyzate results after different enzymatic hydrolysis treatments of mulberries

[0031]

[0032] It can be seen from Table 1 that the cel...

Embodiment 2

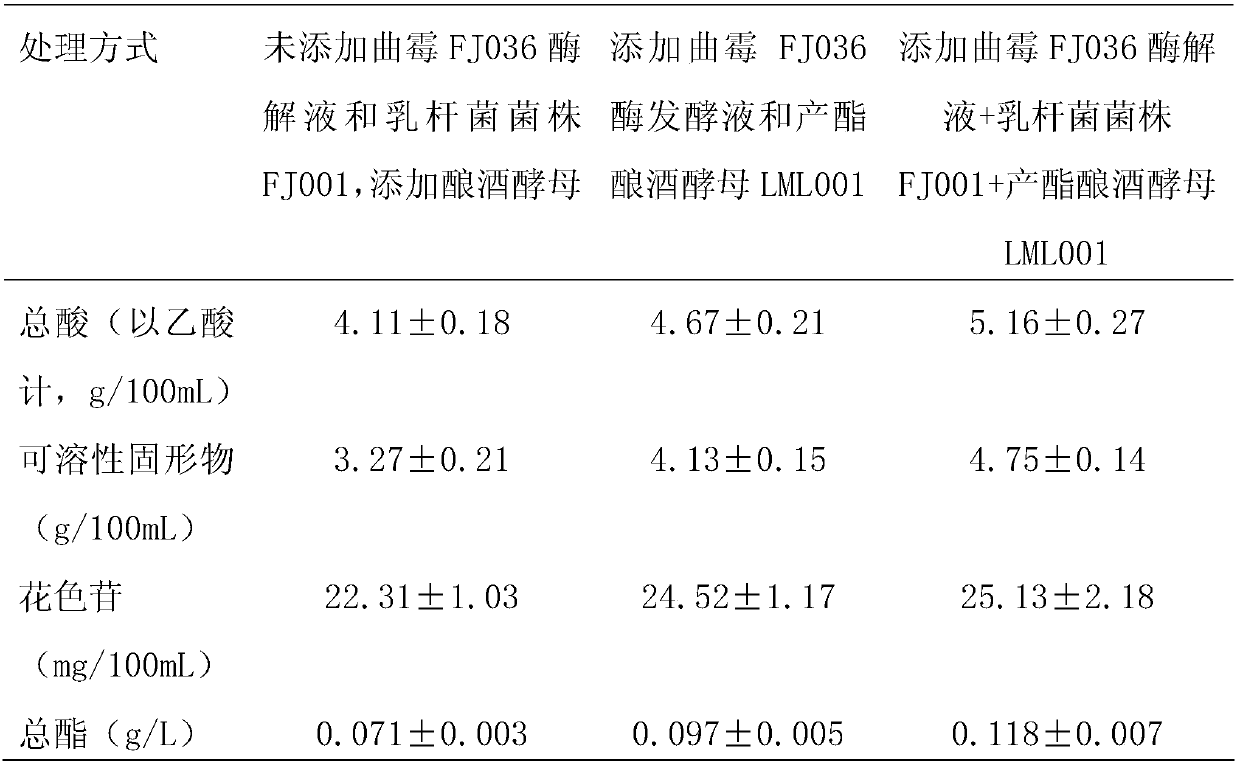

[0033] Embodiment 2: the preparation of mulberry rice vinegar

[0034] The parts by weight of each component of the raw material are:

[0035] 15 parts of mulberry enzymatic hydrolysis solution, 45 parts of glutinous rice, 0.9 part of Jimo old wine koji, 3 parts of ester-producing Saccharomyces cerevisiae seed solution, 0.5 part of Lactobacillus seed solution, 3 parts of Shanghai brewing 1.01 seed solution, and purified water to 100 parts.

[0036] The production steps are:

[0037] 1. Selection and treatment of glutinous rice: uniform glutinous rice particles, 110% to 120% moistening, steaming conditions: 100°C, 20min.

[0038] 2. Selection of mulberries: Choose fresh mulberries with a maturity of more than 90% that are disease-free, insect-free, rot-free, odor-free, pesticide residues and harmful metals do not exceed the standard, and cleaned.

[0039] 3. Beating of mulberries: Destemming and beating of fresh mulberries.

[0040] 4. Preparation of Aspergillus FJ036 enzyme...

Embodiment 3

[0053] A kind of mulberry rice vinegar, the weight portion of each component of raw material is:

[0054] 50 parts of mulberry enzymatic hydrolysis solution, 10 parts of glutinous rice, 0.2 parts of Jimo old wine koji, 3 parts of ester-producing Saccharomyces cerevisiae seed solution, 0.3 parts of Lactobacillus seed solution, 3 parts of Hu Niu 1.01 seed solution, and purified water to make up to 100 parts.

[0055] A kind of mulberry rice vinegar, preparation technology is:

[0056] The preparation method of above-mentioned mulberry rice vinegar, its preparation steps are:

[0057] 1. Material selection and processing of glutinous rice: the glutinous rice particles are uniform, the moisturizing amount is 110% to 120%, and the steaming conditions: 100 ℃, 20min.

[0058] 2. Material selection of mulberries: choose fresh mulberries with a maturity of more than 90% that are free of disease, no insects, no decay, no peculiar smell, no pesticide residues and harmful metals exceedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com